Chapter 5 – Product Flow Control

Firmware Version 3/4.31.37

5.2.5 2”-3” DIGITAL CONTROL VALVES

Once the digital control valve, needle valve adjustments are correctly set, digital valve control is not a problem.

But with small 2”-3” digital valves or valves that do not contain needle valve adjusters, these valves tend to react

very quickly and sometimes result in constant overshooting of the target flow rate, especially at low flow rates.

This can be observed as the valve fails to lock into a steady flow rate while the solenoids continue to click

throughout the load.

To prevent this problem an alternative flow algorithm can be configured. This algorithm makes small steps in the

adjustment of the digital control valve eliminating the overshoot and allowing a reduction in the flow deadband

values. Changing the length of time the solenoid is strobed (Valve Dwell Time) will allow software adjustment of

the valve speed similar to the way a needle valve adjusts the valve speed.

MultiLoad can be configured to use this alternate digital control valve algorithm by configuring as follows:

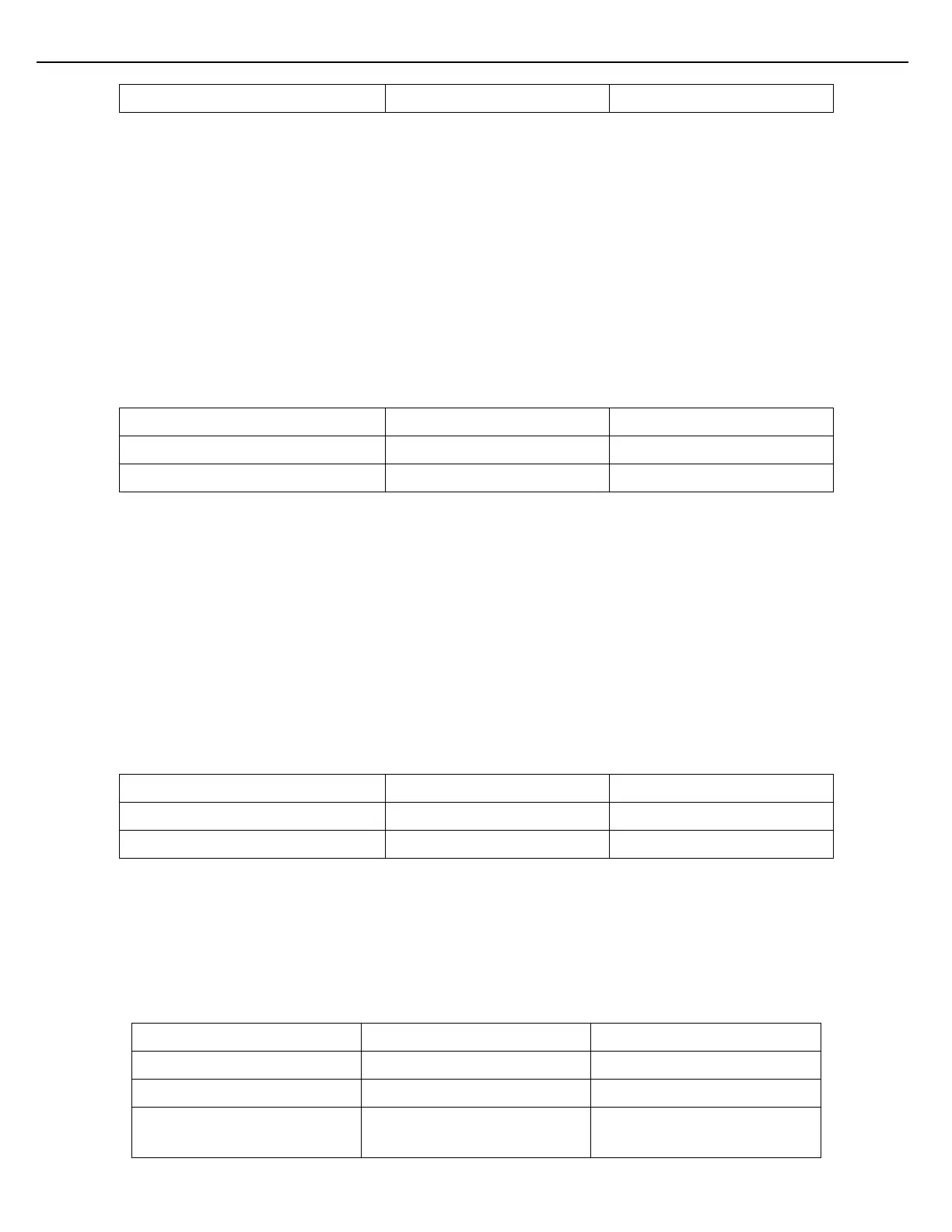

Navigate to: Program Mode->Configuration->Equipment Setup and configure the following parameters:

To increase the speed of adjustment, increase the Valve Dwell Time by 0.005 up to no more than 0.170 seconds.

To decrease the speed of adjustment, decrease the Valve Dwell Time by 0.005 down to no less than 0.030

seconds.

5.2.6 ADAPTIVE DIGITAL CONTROL ALGORITHM

To increase the accuracy of targeting flow rates, an Adaptive Digital Control Valve Algorithm has been developed.

This algorithm notes the adjustment speed of the digital control valve with the current flow and valve conditions,

and adjusts its control method to target as close as possible to the target flow rate. Once locked into this target

flow rate the next adjustment will not occur until the current flow rate falls outside the target deadband.

With FCM or I/O Board versions 037 and later, MultiLoad can be configured to use this Adaptive Digital Control

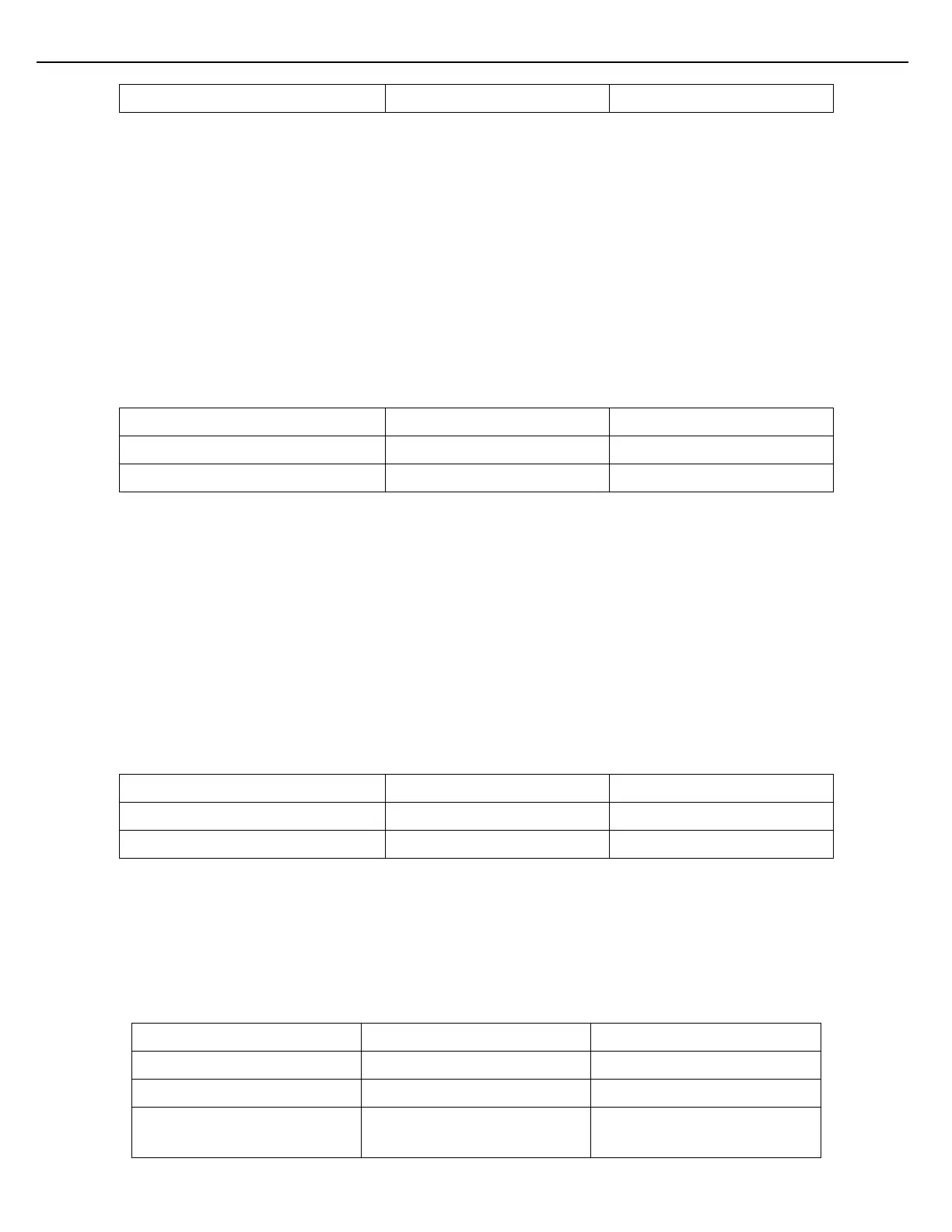

Valve Algorithm by configuring as follows:

Navigate to: Program Mode->Configuration->Equipment Setup and configure the following parameters:

5.2.7 TWO STAGE VALVES

Two stage valves are similar to Digital control valves in that they both operate using Normally Open (NO) and

Normally Closed (NC) solenoids. The two stage valve provides only two flow rates however, Low and High.

MultiLoad can handle two stage valves through proper configuration as follows:

Navigate to: Program Mode->Configuration->Equipment Setup and configure the following parameters:

1st Stage Flow Rate: 5000

Excess Flw Alrm Rate:

> Max anticipated flow rate

2nd Stage Trip Vol: 0

Fallback Time: 0

Loading...

Loading...