Firmware Version 3/4.31.37

6.11.2 TECHNIQUES FOR FLUSHING DYE

Front Loading Dye

The flush cycle can be maximized by injecting the load’s entire dye requirement at the very beginning of the

delivery cycle. Flushing will occur for the majority of the load; the load will be over additized during most of the

delivery. The Last Injection From End Volume can be set to a number that is equal to the maximum allowable

preset quantity. This will cause the final injection to occur as soon as the batch is started. The Shutoff Volume

From End should be set to a volume that is less than the Last Injection From End Volume. It may be necessary to

experiment with this value. Find a volume range that provides enough time for the entire dye requirement to be

delivered.

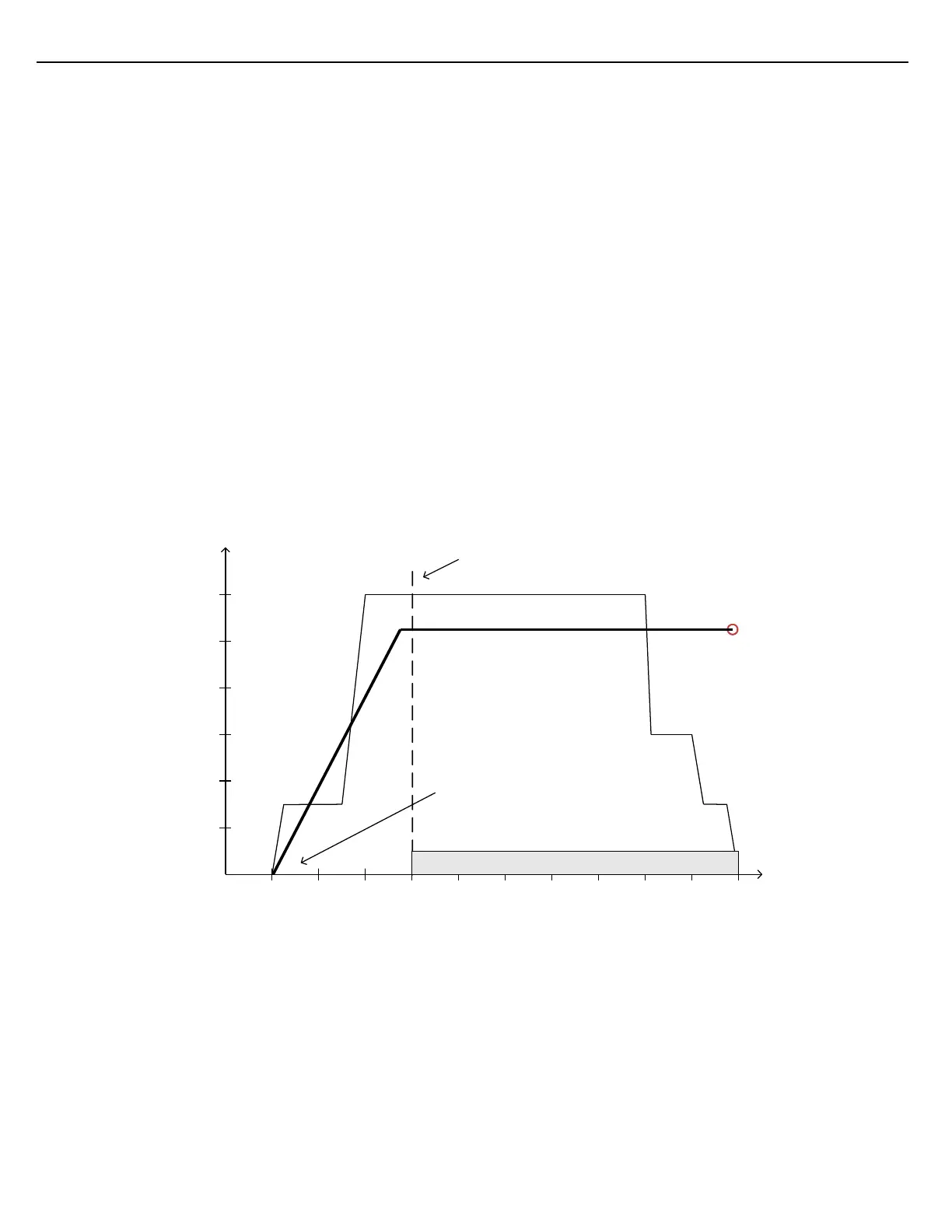

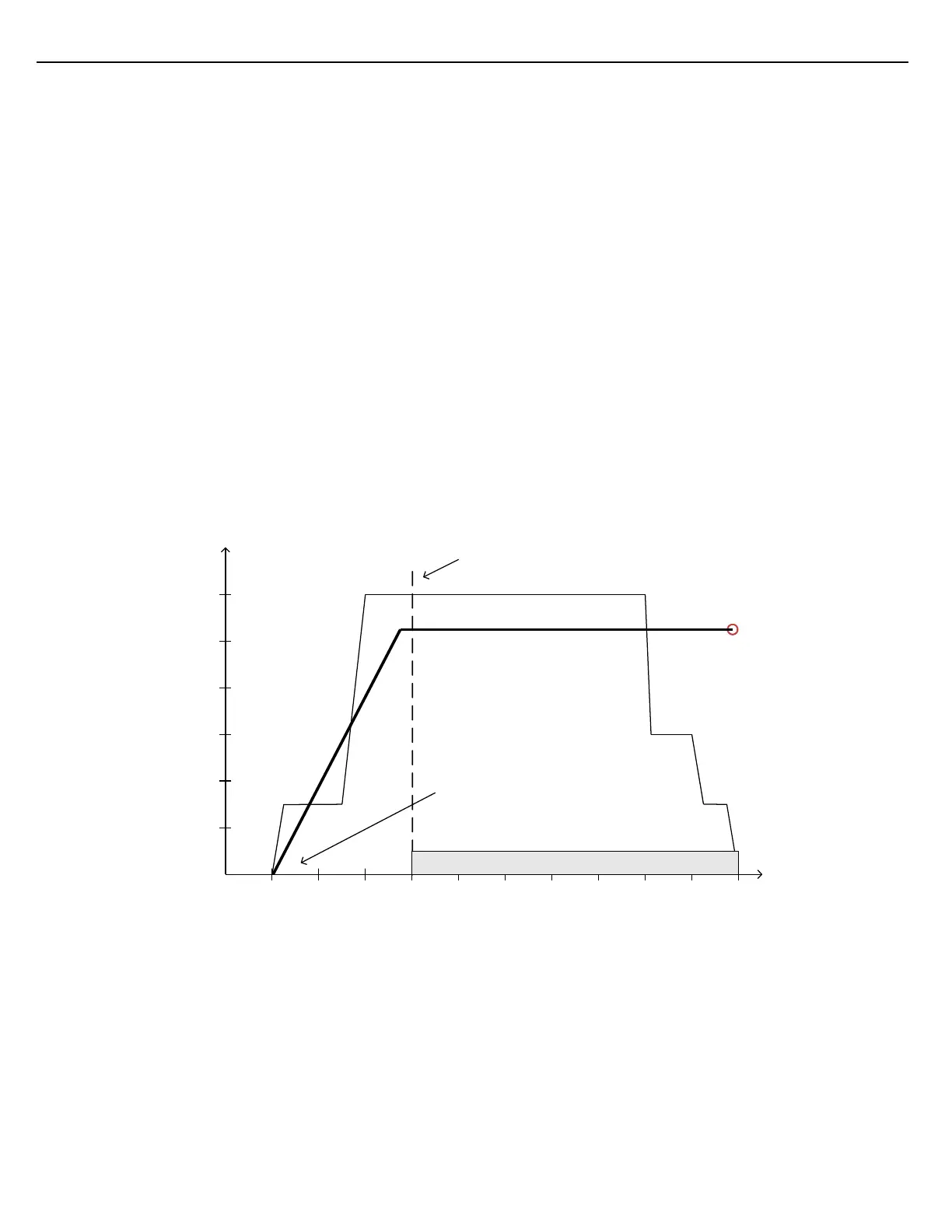

Consider the example in the diagram below. The Last Injection Volume From End is set at 1000 gallons. In a

1000 gallon batch, the dye will begin its final injection immediately. Since the additive Shutoff Volume is set to

700 gallons, the entire volume of dye required for a 1000 gallon batch must be delivered within the first 300

gallons of the load. This example may or may not be practical depending on the recipe amount and the hydraulic

characteristics of the system. The remaining volume of the load can be used to flush the line. The Minimum

Flush Volume can be extended to 700 gallons or less. If the load is aborted before a minimum amount of flush

volume has passed, an Additive Flush alarm will occur.

Loading...

Loading...