Firmware Version 3/4.31.37

When an injection is commanded, the piston must leave its starting position before the Throw Time has elapsed.

The Piston Input (feedback switch) should indicate a change of state when the piston has been launched. The

default state is high when the piston is in the starting position, changing to a low state as the piston travels away

from its seat. If the Piston Input signal changes to a low state before the Throw Time elapses, the Throw Time

timer is reset, pending a command for the piston to return. If the state does not change within the Throw Time, a

missed injection will be logged internally. The load can be programmed to raise an alarm after a number of

missed injections are logged.

When the Throw Time has elapsed, the additive output (injection) signal will be removed, permitting the piston to

return to the starting position. After the output signal has been removed, the Throw Time timer is restarted. The

piston must return to the starting position before the Throw Time has elapsed. If the piston returns to its starting

position before the Throw Time elapses, the state should change to a high condition. The system would assume

that the injection was successful and it would increment the additive totalizer by the quantity specified in the

Volume per Injection parameter. If the signal did not change to a high state before the Throw Time elapsed, a

missed injection would be logged internally. The system will immediately attempt another injection, assuming that

the previous attempt delivered no additive. When the number of missed injections equals the value entered for the

Max Pstn Missed Inj (Maximum Piston Missed Injections) parameter, an Injection Fault alarm will be raised and

the load will be stopped.

If the piston has successfully returned to its starting position, as determined by the feedback signal, the piston will

sit idle until another injection signal is received from the additive output port. Another injection command signal

shall be sent to the injector when the demand for additive, based on product delivery, becomes 50% of one

injection volume.

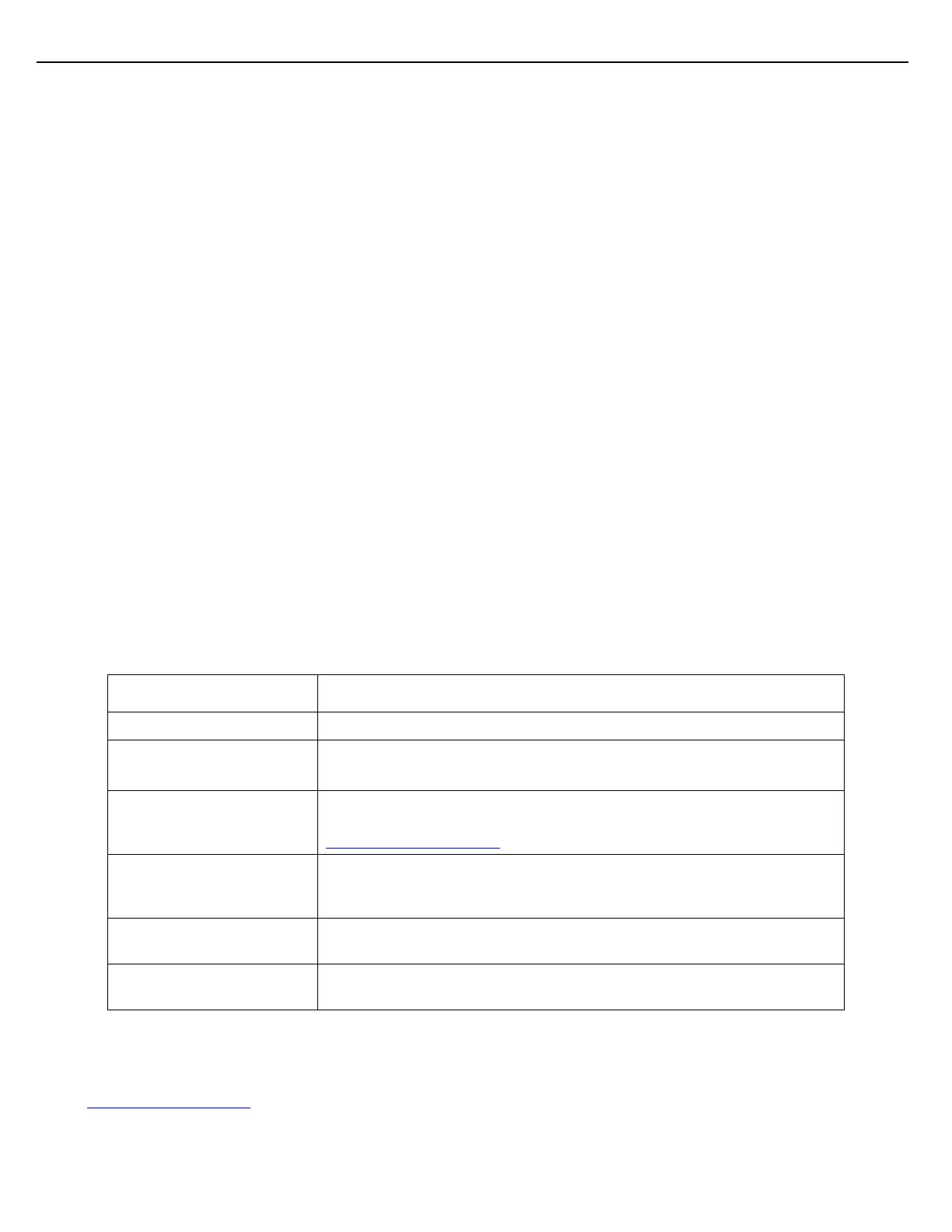

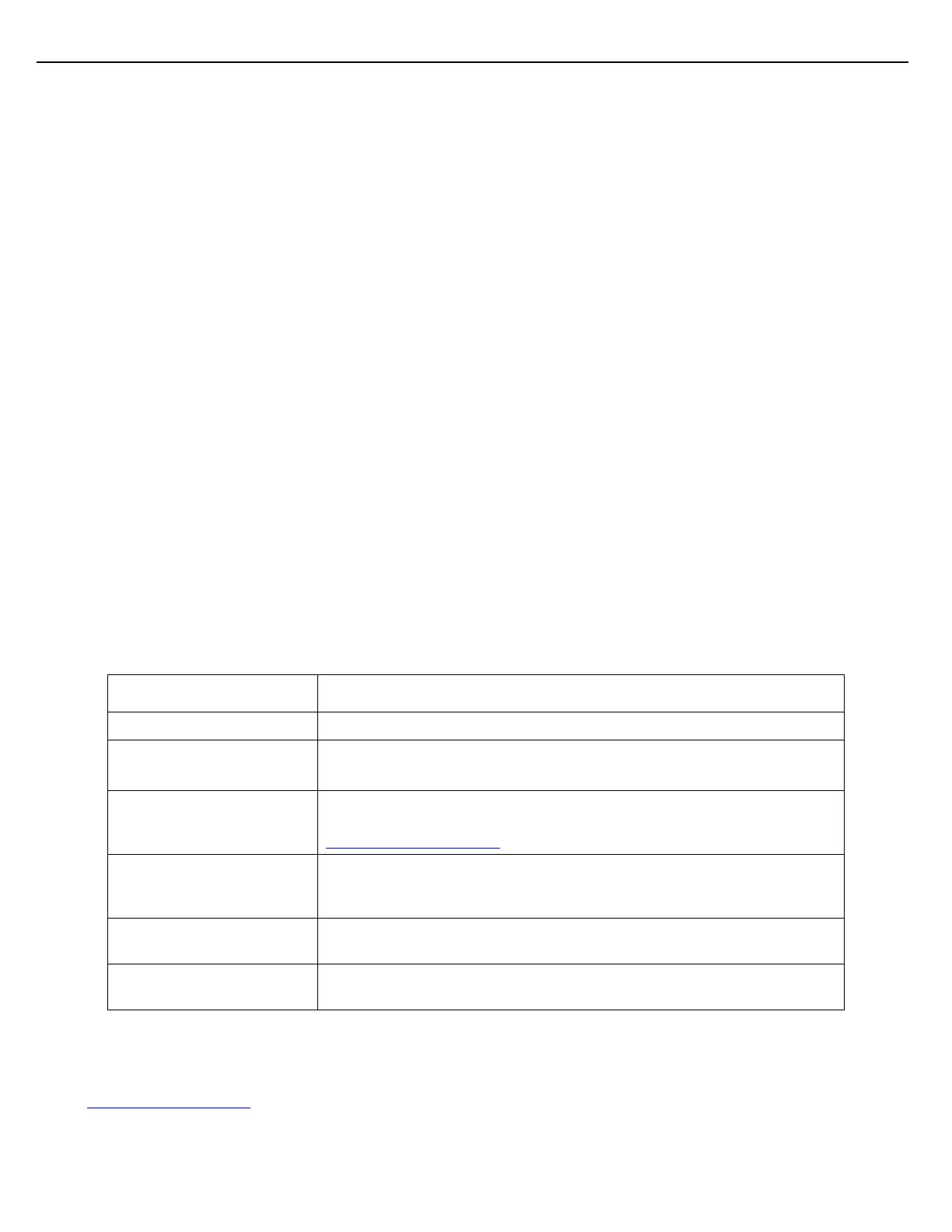

6.5.4 CONFIGURING A PISTON WITH INPUT ADDITIVE

This topic describes the minimum configuration required to get an additive to operate using this method.

Configuration of the following parameters is mandatory. Using the MultiLoad II Configuration Tool or the Remote

Control Unit keypad in Program mode, select the preset and additive desired.

Loading...

Loading...