Firmware Version 3/4.31.37

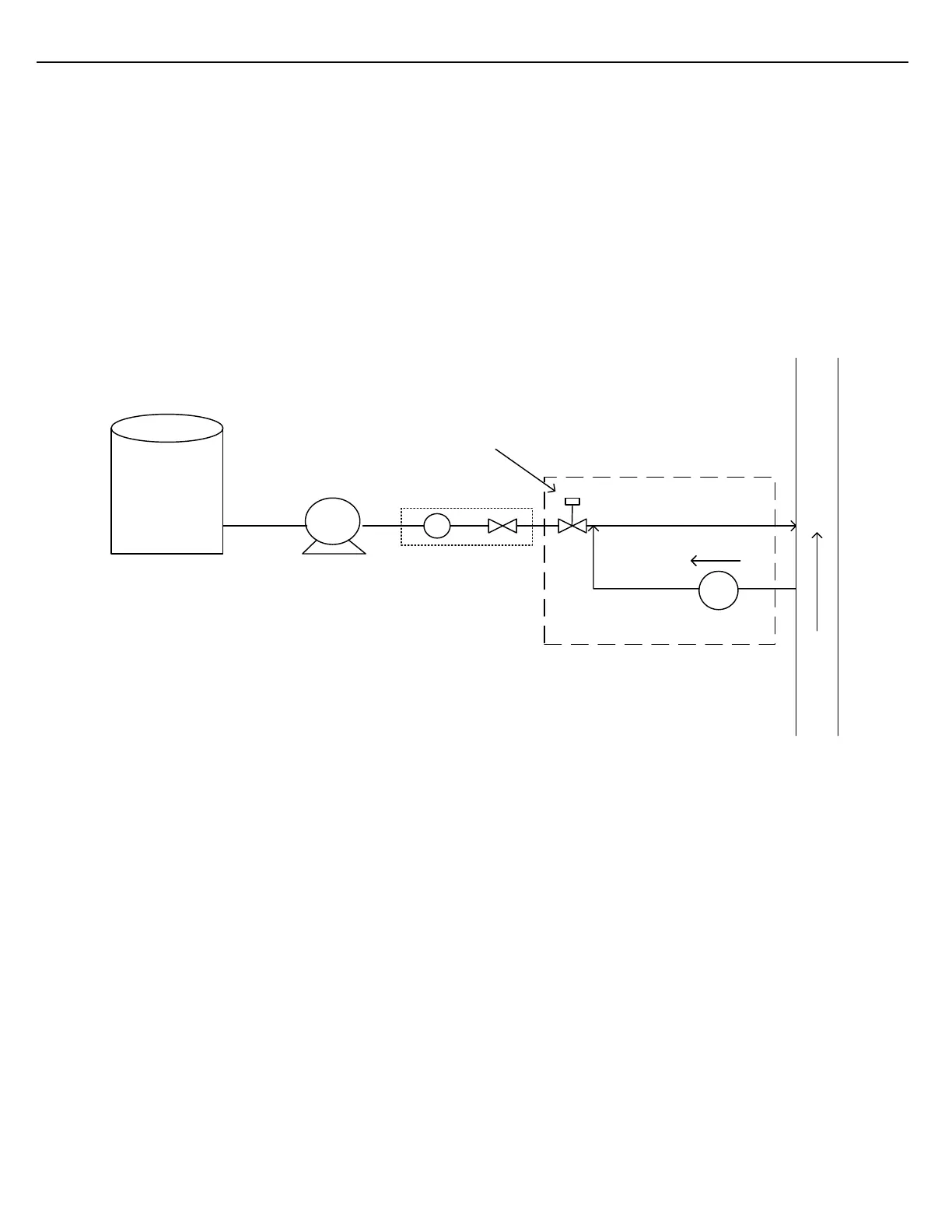

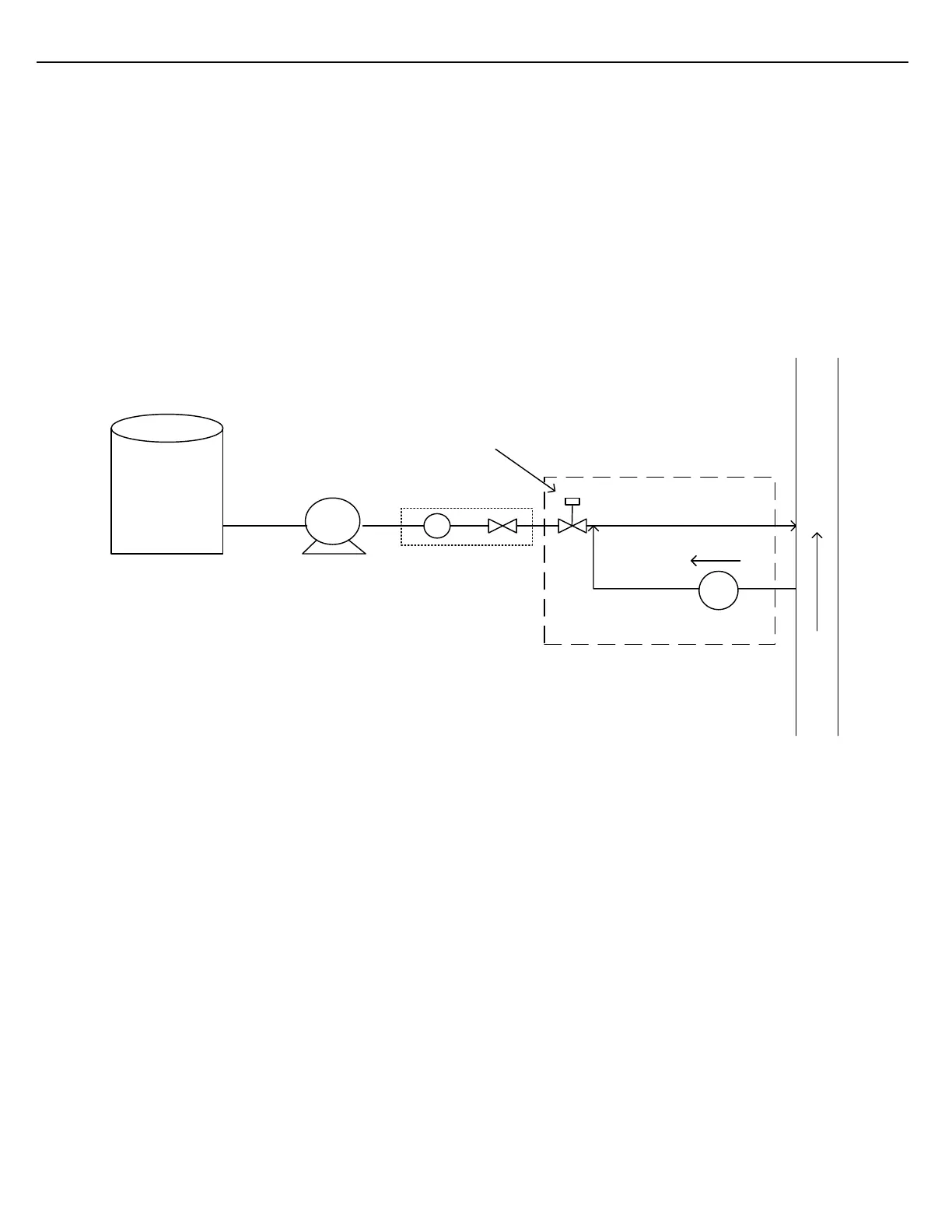

6.11.3 BLOCK VALVES AND FLUSH PUMPS

Functionality exists in the MultiLoad II to support additive Block Valves and/or Flush Pumps. The Block Valves

are mounted downstream of the additive meter and injector valve. The additive meter and injector valve are often

integrated into a mono-block assembly. The Block Valve will reside downstream of the mono-block assembly as

insurance against dye leaking past the assembly, while in an idle state.

The Block Valve will open when the MultiLoad II’s Start button is pressed. The Block Valve will close as soon as

the volume specified by the Shutoff Volume From End parameter is reached.

Flush Pumps have been devised to prevent dye from clinging to the output orifice of the Block Valve. After the

final injection has been made and the Block Valve closes, the Flush Pump will activate for a pre-programmed

period. The Flush Pump will circulate product across the Block Valve orifice, dislodging residual dye.

Figure 6.11 Mono-block Injector & Dye Point Assembly

To configure for a Block Valve, find the Open Blk Val FCM# parameter in the additive section. Assign an FCM

and port to perform this function. For valves that require a separate closing signal and/or a valve status signal,

ports can also be assigned for these functions.

To configure for a Flush Pump, find the Flush Pump Run FCM# parameter to assign a port for this function.

Determine the amount of time required for an adequate flush and enter this value, in seconds, into the Flush

Pump Run Time parameter.

Loading...

Loading...