Firmware Version 3/4.31.37

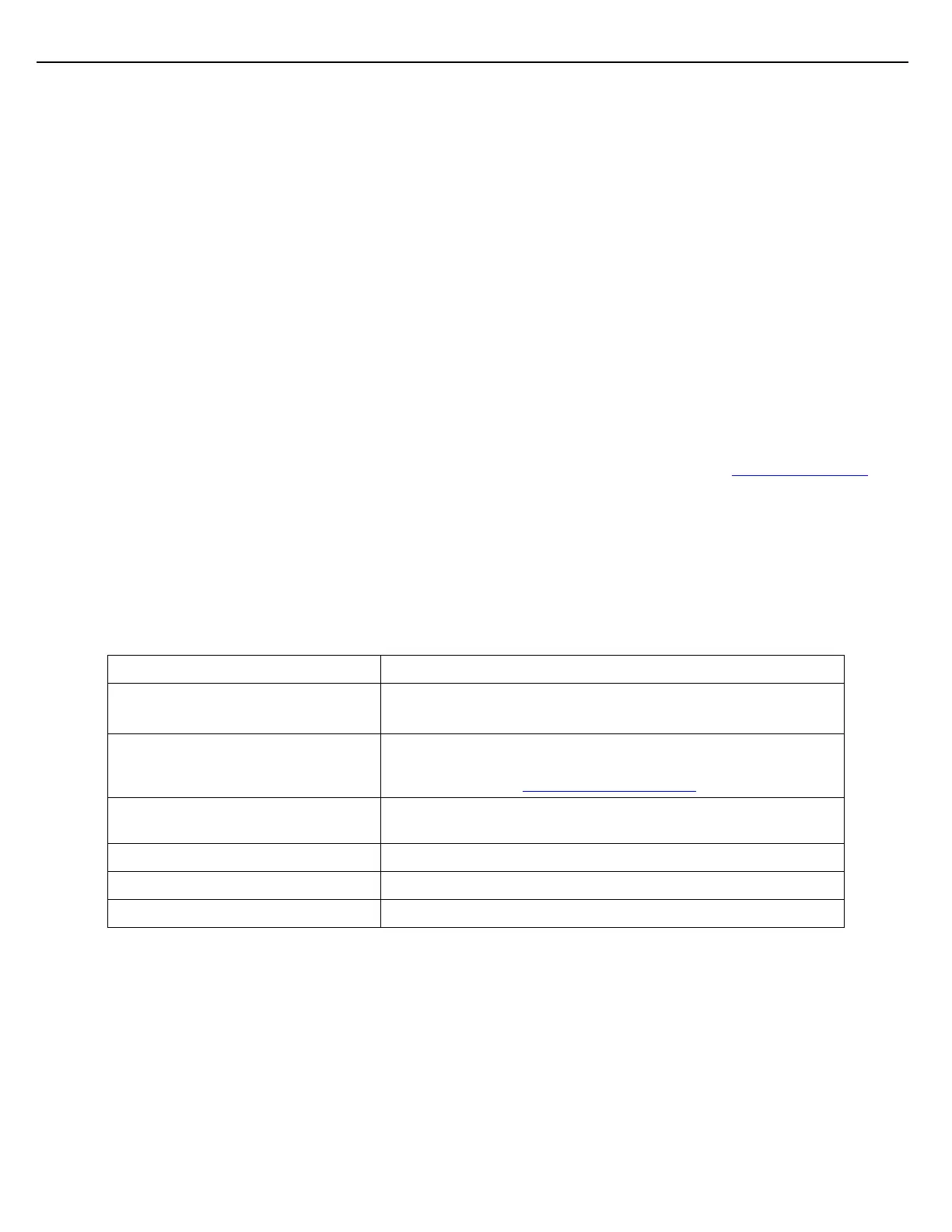

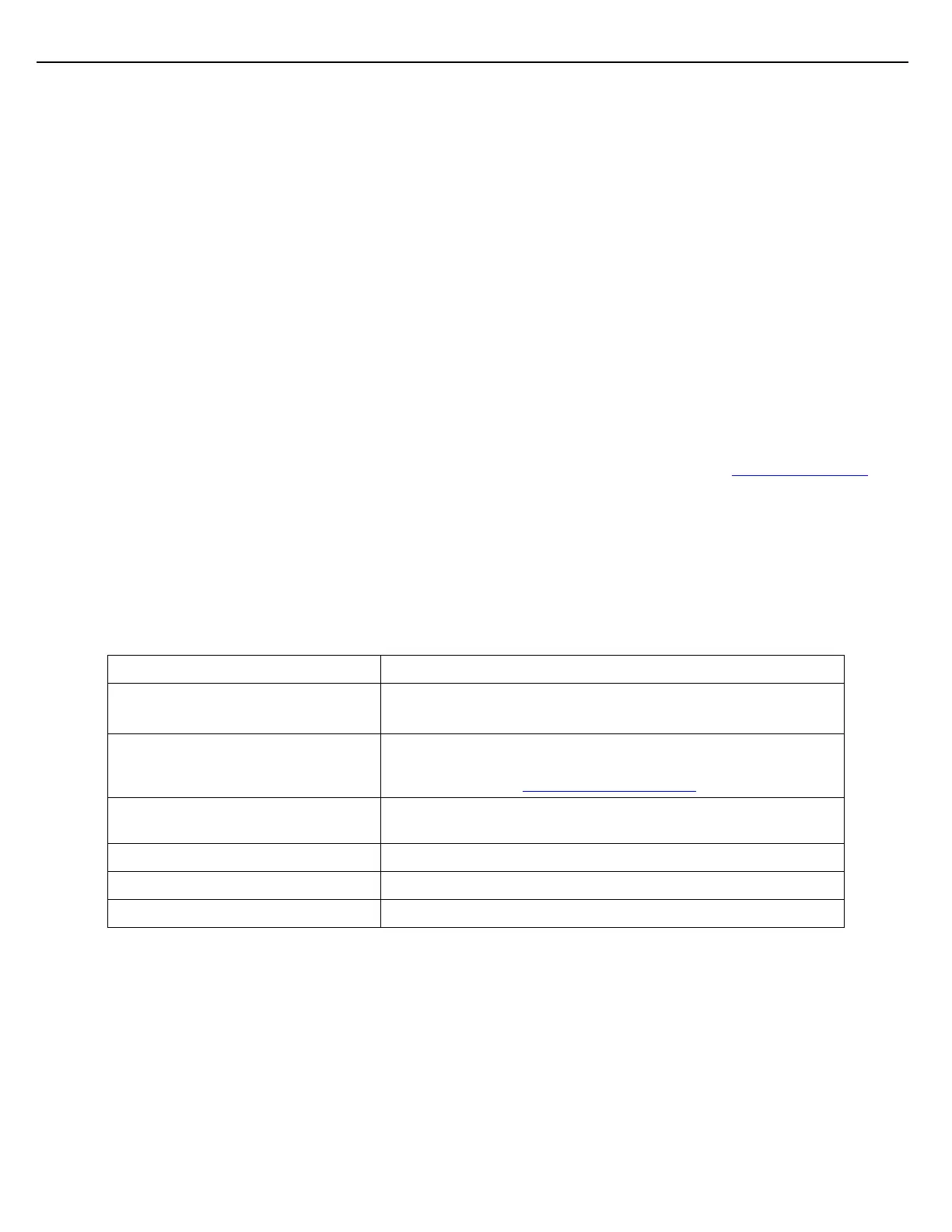

The “Parameters for Additive Methods” table identifies the parameters that apply to this method.

6.5.5 METHOD 3 – PULSER INPUT

This configuration assumes that a flow measurement device is metering the amount of additive entering the

product stream. It is assumed that there is no piston/cylinder and that the additive output port is commanding a

solenoid operated valve, which controls the delivery of additive. Instead of incrementing the additive totalizer at

each injection or upon receipt of a feedback signal, this feature updates the additive totalizers based upon

measured flow.

Because the physical limitations of a piston/cylinder injector are eliminated, the Throw Time parameter is

irrelevant. The Volume Per Injection parameter is still valid, however. The Volume Per Injection parameter sets a

target pace that the system will inject, if necessary, in order to eliminate a deficit.

The Solenoid Shut Pulses parameter applies only to the Pulser Input additive method. Its purpose is to

compensate for the closing speed of the solenoid valve, which may allow a slight, but consistent over-delivery of

additive (non-cumulative). Compensation is accomplished on a pulse basis rather than a volumetric basis. This

feature is intended to eliminate the remaining over-delivery, assuming mechanical adjustments to the solenoid

valve's closing speed have already been made. The quantity of pulse overruns due to valve action can be

determined by performing the Additive Calibration test or the Additive Diagnostic Test Injection. The quantity of

excess pulses delivered for each test injection can be observed. When the number of overrun pulses is

determined, enter the number into this parameter to further reduce the overrun. (See the Additive Calibration

topic later in this chapter for details.)

6.5.6 CONFIGURING A PULSER INPUT ADDITIVE

This topic describes the minimum configuration needed to get an additive to operate using this method.

Configuration of the following parameters is mandatory. You can accomplish this using the MultiLoad II

Configuration Tool or the MultiLoad II keypad in Program mode. Select the preset and additive desired.

The remaining parameters that apply to this additive method are optional. They are used to set up alarming,

pump outputs and permissive inputs. Some of the remaining parameters affect how the additive is delivered at

different stages of the load cycle. All Additive configuration screens and parameter descriptions are found in the

‘General Additive Setup’ section that follows.

The “Parameters for Additive Methods” table lists the parameters that apply to this method.

Loading...

Loading...