Chapter 5 – Product Flow Control

Firmware Version 3/4.31.37

5.2.8 ANALOG VALVES

Analog valves are control valves that operate from a 4-20mA signal that indicates the proportional opening of the

valve.

An analog signal of less than or equal to 4mA will drive the valve completely closed (0%).

An analog signal of greater than or equal to 20mA will drive the valve completely open (100%).

An analog signal between 4mA and 20mA will drive the valve to a percent open between 0% and 100%.

An analog valve by itself does not target a flow rate, so the valve control signal will be adjusted by MultiLoad to

target a flow rate profile.

With FCM or I/O Board versions 037 and later, MultiLoad can handle analog valves through proper configuration

as follows:

Navigate to: Program Mode->Configuration->Equipment Setup and configure the following parameters:

To change the speed of positive flow changes, modify the 4-20mA Increase Step.

To change the speed of negative flow changes, modify the 4-20mA Decrease Step.

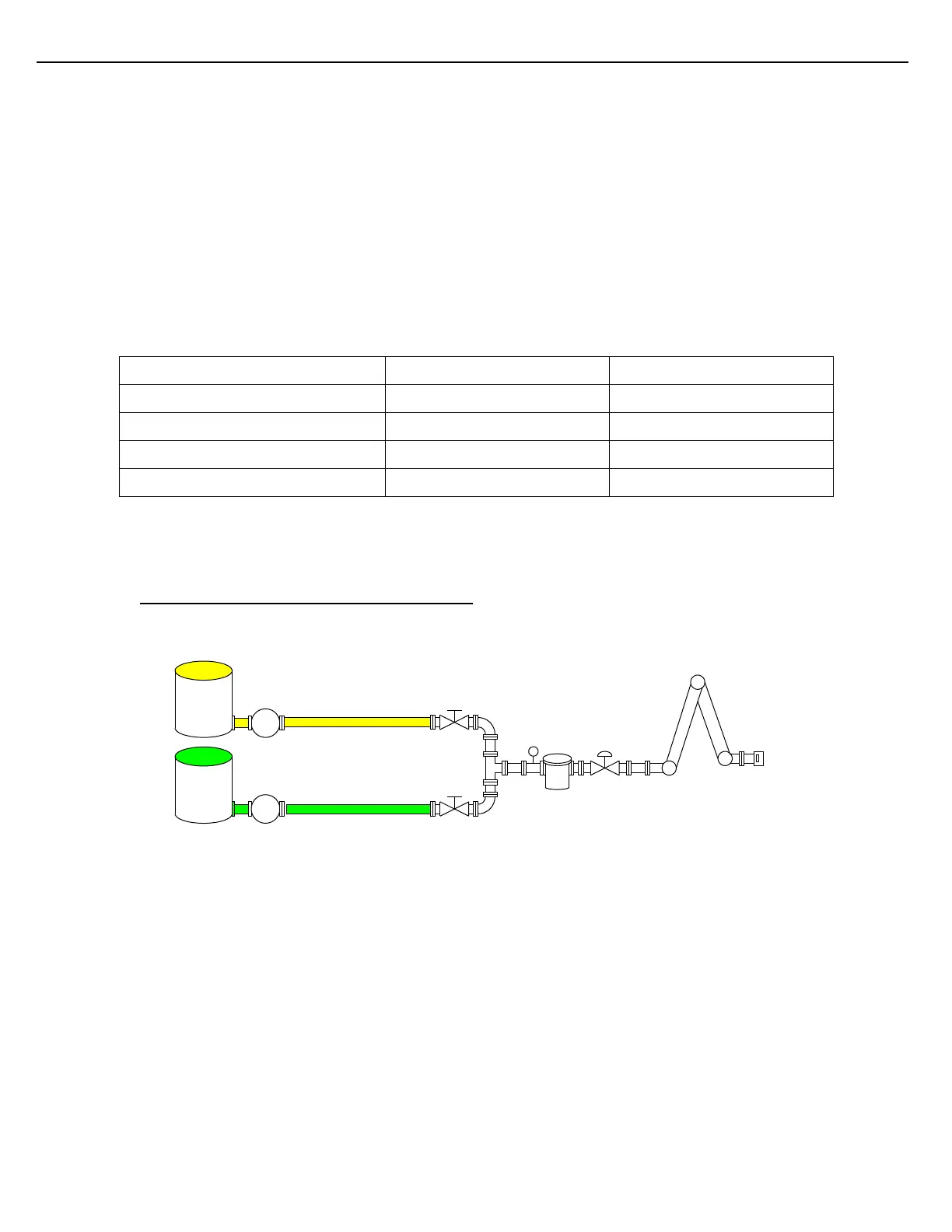

5.3 SEQUENTIAL BLENDING (EXCLUDING SMP)

P

P

Premium

Regular

BV

T1

CV

M1

BV

Comp #1

Comp #2

Figure 5.3 Sequential Blending Application

The Sequential Blending feature is used when loading two to eight (2 – 8) components together in a compartment

to make a single product. Typically the components will be delivered one at a time through the same load arm,

using one flow meter and one digital control valve.

Block valves, which serve as component selection valves, must be used to ensure loading of the proper

component in the proper sequence. These valves can be motor operated (MOV) or they can be manually

operated. In case, a block valve status or feedback signal can be employed to verify that the valves are in the

proper position at all times during the loading sequence.

The flow profile control sequence used in Sequential Blending is very similar to the sequence used for single

product loading. The sequence is repeated for each component that is used in the product recipe. The first

component of the blend will cycle through the following phases:

- Low Flow Start

- High Flow

- 1st Stage Trip

Loading...

Loading...