Firmware Version 3/4.31.37

3.13.2 CONNECTION TO THE MULTILOAD II

Setup a connection to the MultiLoad II via serial, tms5/6 or Ethernet

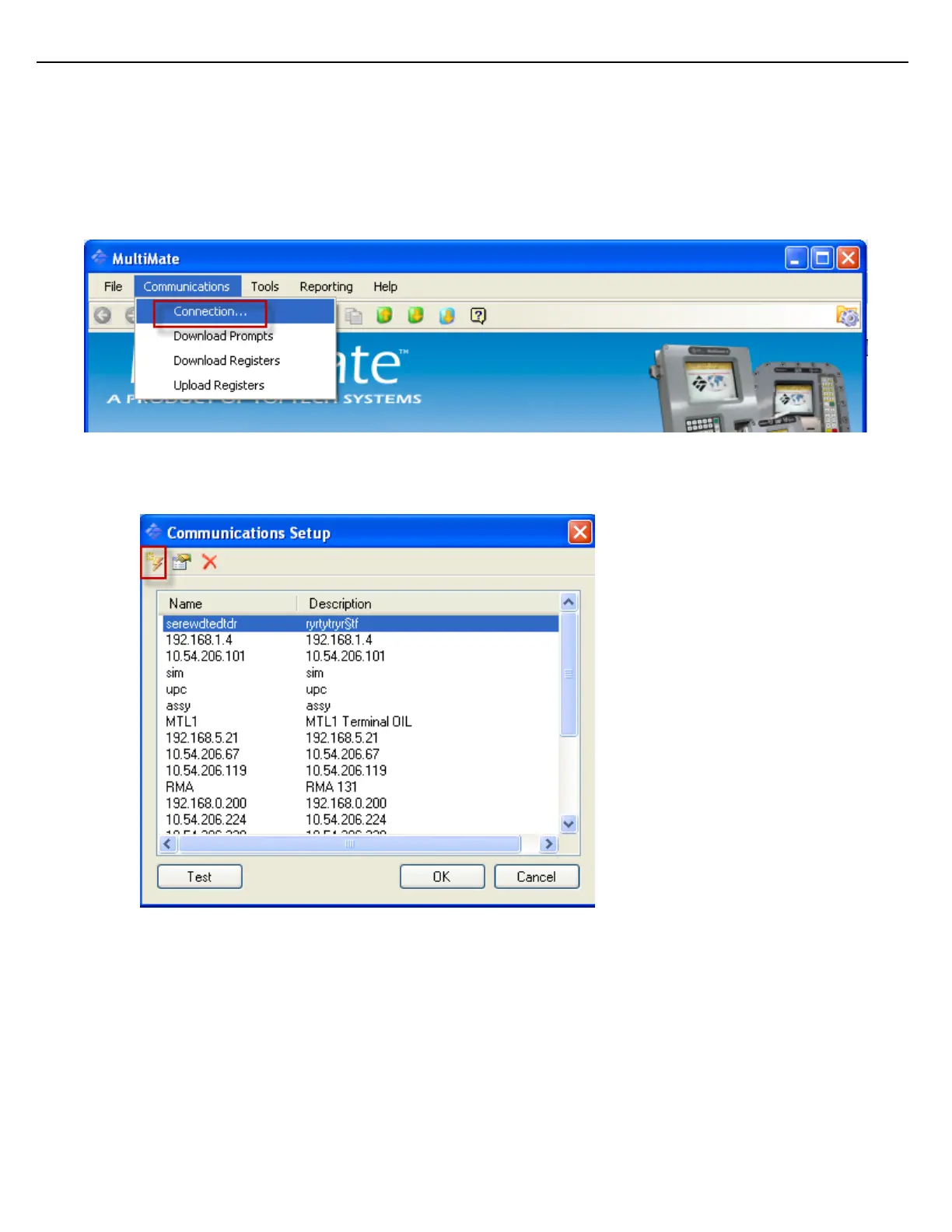

1. Go to the menu Communications and select Connection…

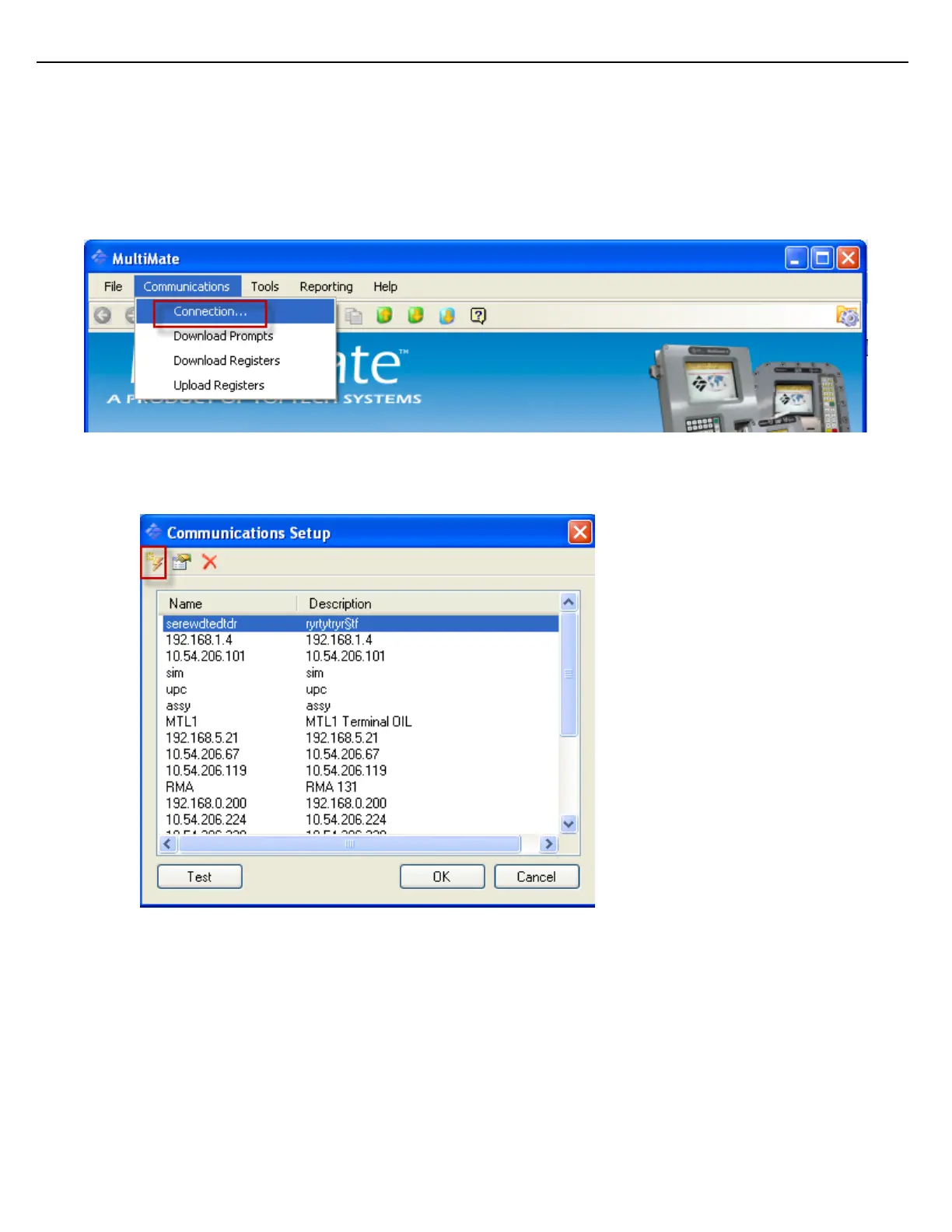

2. A new screen will pop up. In this screen in the left upper corner the button new connection should be

pushed.

Loading...

Loading...