Firmware Version 3/4.31.37

5.9 RATIO BLENDING CONSIDERATIONS (EXCLUDING SMP)

When Ratio Blending, all product recipe components are flowing simultaneously. Any time Ratio Blending is

occurring, a flush requirement appears on the Status screen, since a mixture of components exists in the line.

Before the ratio-blended load begins, the algorithm decides which component to short. When the remaining

preset quantity is equal to the Line Flush Volume, the flow of all blended components is stopped. Then the flush

stage will begin, where only the Line Flush Component is flowing. All non-flush components in the product recipe

must have delivered their required volumes by this time. When blends are aborted before flush occurs or before

the Line Flush Minimum Volume has been delivered, the Line Flush alarm is activated. The volume of flush error

will be displayed on the Status screen.

If flush is involved with ratio blending, the setting of the Blend Check Alarm % can prevent loads of certain

quantities from being delivered, because the blend will be forced to be temporarily out of specification prior to

beginning the flush phase. This determination is made before loading starts.

Example

The Blend Check Alarm % is set to 5% and a preset of 1000 gallons is selected for a 60/40 load in which

component #2 is the flush component. The Flush Volume is 100 gallons. The 600 gallon requirement of

component #1 has to be completely delivered by the time the last 100 gallons of flush is started. When ratio flow

stops to begin the flush phase and before the flush is started the ratio will be 600/300. This will result in a 6.7%

error until the flush begins. The load will be stopped for a blend specification violation. To deliver 1000 gallon

loads in this case, the Blend Check % alarm setting will have to be relaxed to 7%.

Review the section on Ratio Blending in this chapter for configuration details.

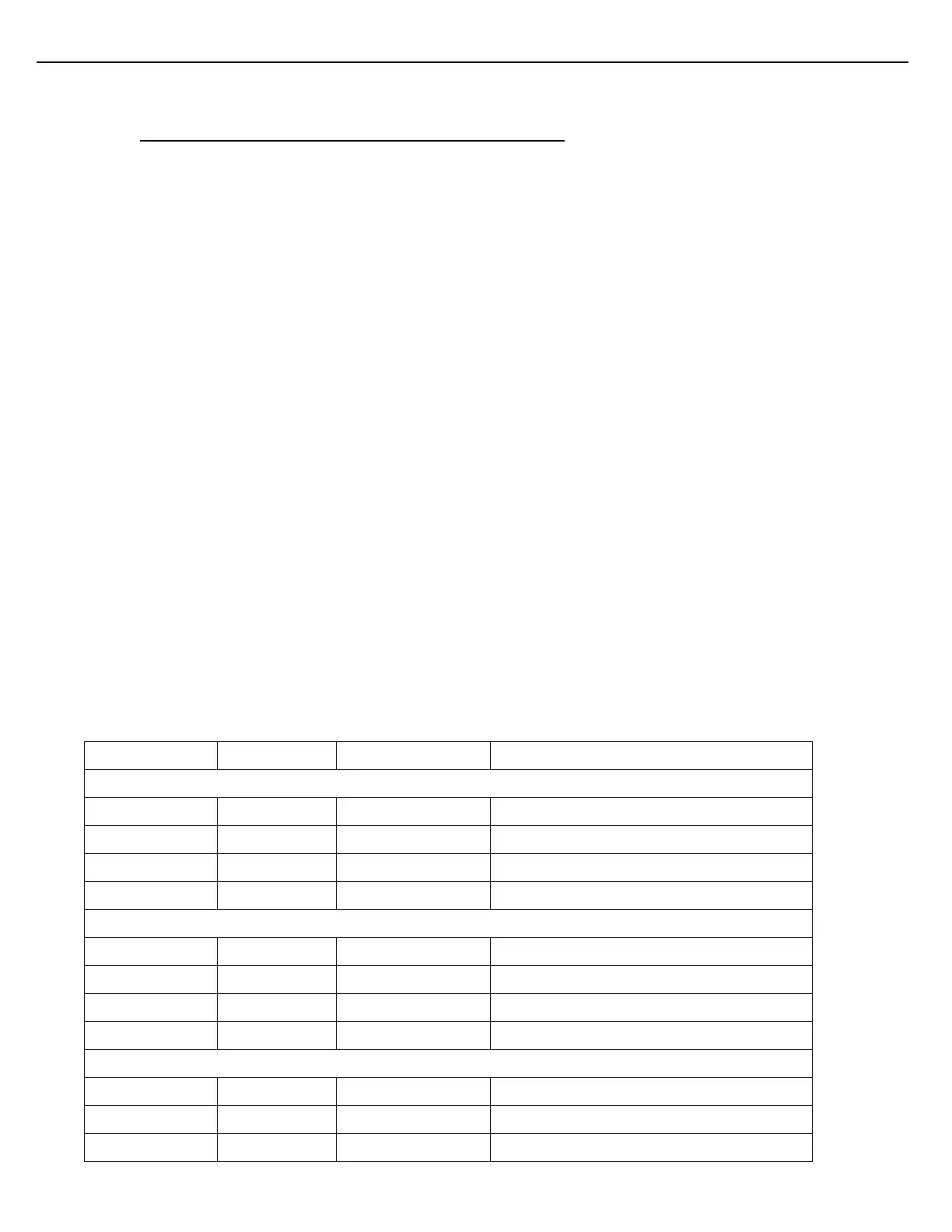

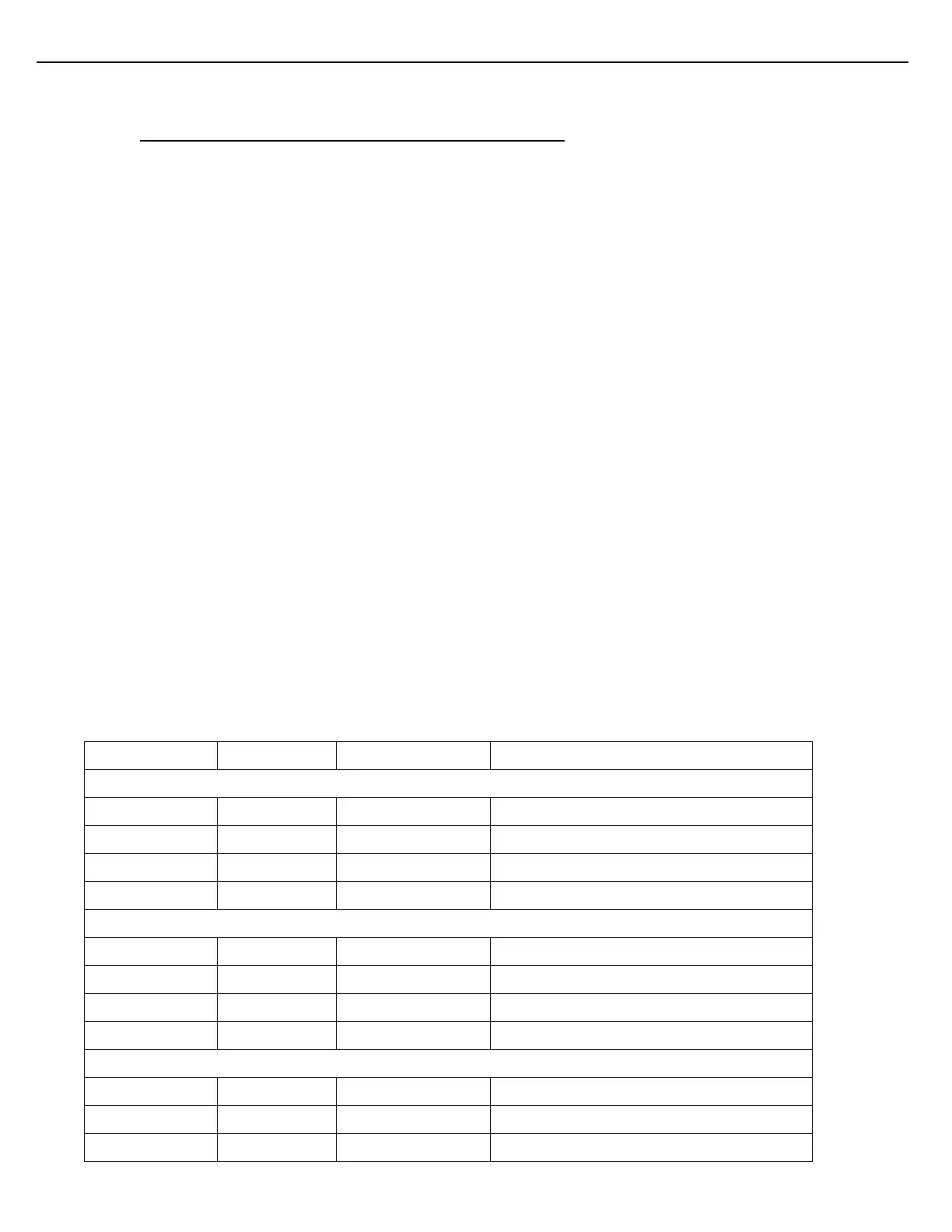

The following table shows how a 1000 gallon load is affected by each of the decision parameters. The product is

a 60/40 blend. Component #1 is 60% of the total and component #2 is 40% of the total. The Line Flush

Component is component #2. The Line Flush Volume is 100 gallons.

Line Flush Delivery for Various Line Flush Options – Ratio Blending

Loading...

Loading...