Setting up Compax3 C3F_T40

100 192-121102 N04 June 2008

Before the activation, please notice the following:

Correct connection of the pressure sensors to the controller.

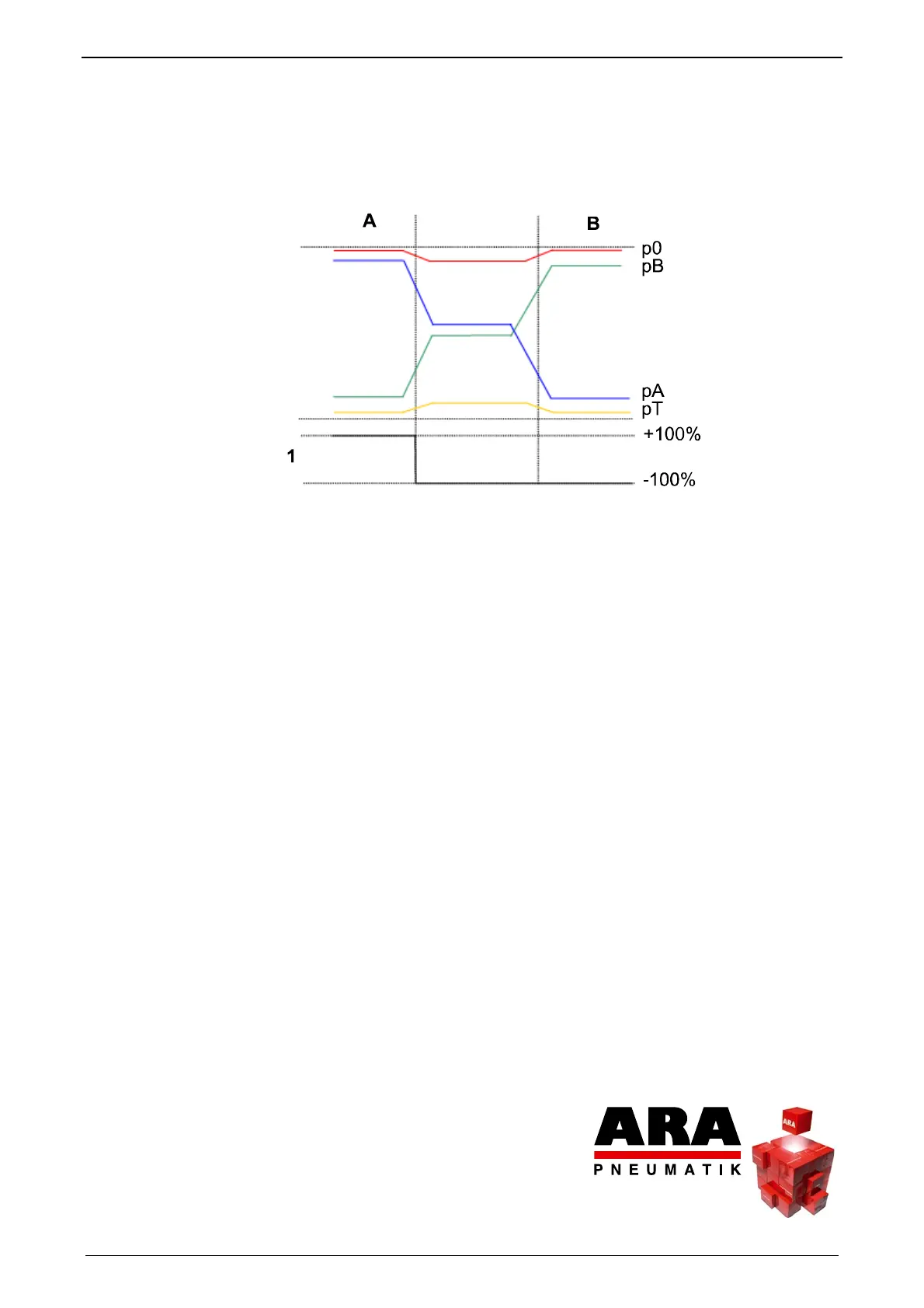

By approaching the end limits and simultaneously monitoring the pressure

values (Status values pressure of main or auxiliary axis pa, pb, pT and p0)

it is possible to conclude if the pressure sensors are correctly assigned.

A = yclinder at limit A

B = cylinder at limit B

1 = valve position

The pressure signals should be well filtered (smooth). (Optimization Analog

input InX Filter)

If those conditions are fulfilled, the pressure compensation can be activated under

(Optimization Output Chain PressureCompensation).

b) characteristics compensation

The control behavior of valves with bent characteristic lines or overlap can be

considerably improved if the valve characteristics are stored in the controller and

are used for the compensation. The characteristic is integrated into the resepective

valve data via the C3HydraulicsManager and is loaded into the controller via the

C3ServoManager. The activation of the characteristic line is made via optimization

Output Chain Characterisitic Flow.

If the valve characteristic line is activated, the behavior between control signal and

speed should be mainly linear.

(Doubling of the setpoint speed Doubling of the resulting speed in the open

control loop).

c) Deadband compensation

If for valves with overlap or gap no adequate characteristics are available, they can

be optimized with the aid of the deadband compensation. The corresponding

values are set in (Optimization Output Chain Deadband ...).

Autoryzowany dystrybutor Parker:

53 -012 Wrocław

ul. Wyścigowa 38

tel. 71

fax

71

w w w . a r a p n e u m a t i k . p l

364 72 82

364 72 83

Loading...

Loading...