Parker EME

Motion control

192-121102 N04 June 2008 209

Compax3 is able to simulate mechanical cams as well as cam switching

mechanisms electronically.

This helps to realize discontinuous material supply, flying knife and similar drive

applications with distributed drive performance.

The compact servo controller processes the position signals of a master axis and

controls a servo motor, torque motor or a direct-drive linear actuator via the desired

motion profile, which is defined in the form of an interpolation point memory. The

combination of drive, control and power unit in one device offers many advantages:

Fast and easy commissioning.

fast and stable control.

feedforward control measures result in reduced need for peak torque and

improved response behavior - therefore following errors are avoided.

central digital control from the setpoint generator to the power output stage.

lower wiring overhead and thus substantially reduced fault liability.

5.10.1.1 Function principle

In this chapter you can read about:

Coupling and decoupling ................................................................................................. 209

Mark synchronization....................................................................................................... 210

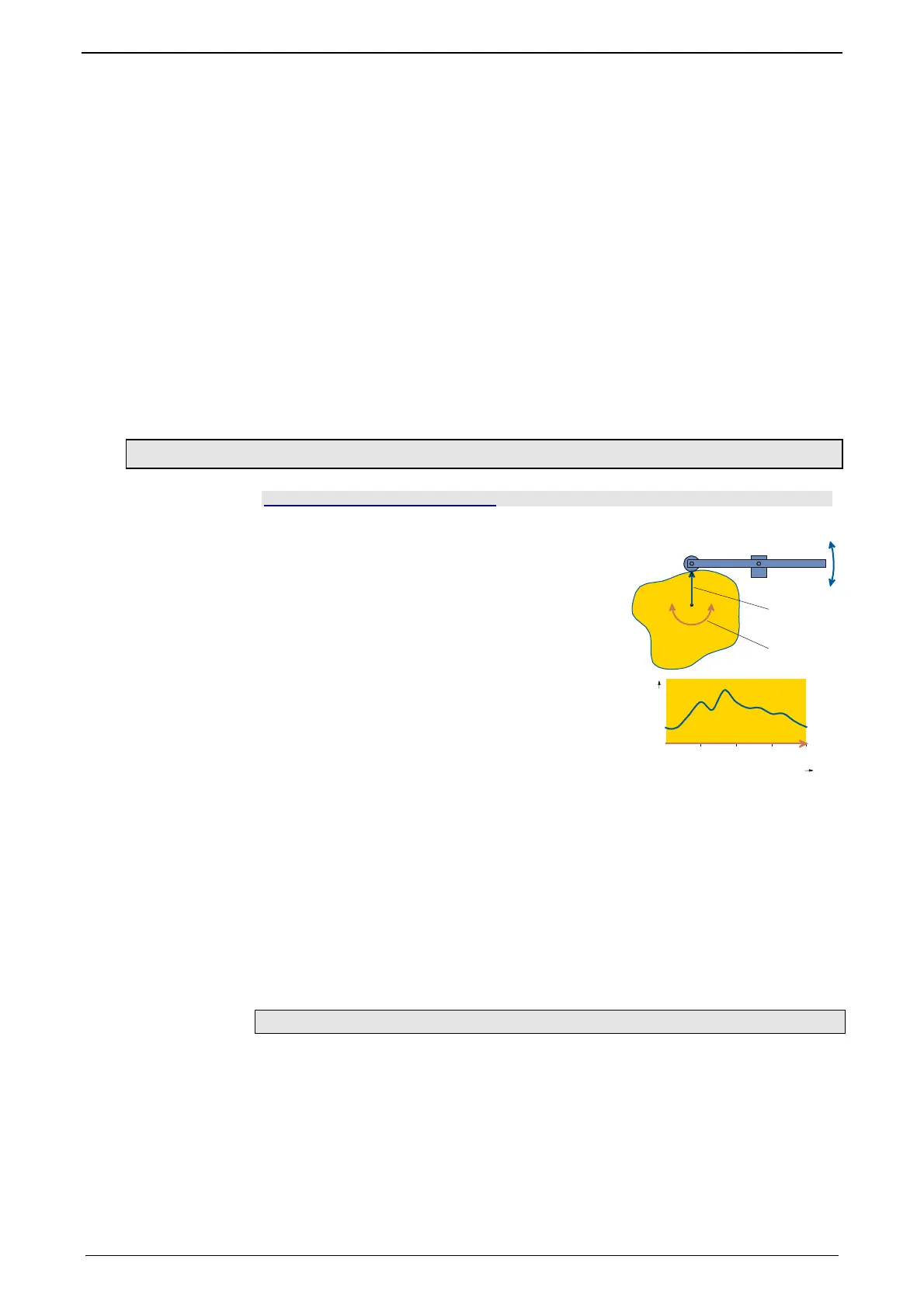

Slave

Master

Slave

Master

90° 180° 270° 360°

Depending on the angle setting of a leading axis (master), the following axis (slave)

is moved according to a user-defined motion profile. The master position moves

within a defined value range; the master clock distance, and moves through it

cyclically. Each cycle corresponds to a revolution of the cam or a repetition cycle of

any complex movement. Via the master position, a sequence of interpolation points

with up to 10000 non-equidistant interpolation points is addressed. Compax3

interpolates linarly between the interpolation points. Those position setpoint values

are used to form the feedforward signals for the subordinate controller cascades of

the following axis. This feedforward of speed and acceleration is used to reduce

the following error of the following axis as fas as possible.

Coupling and decoupling

An important function for complex plants is the coupling and decoupling of

individual drives, triggered by an external control signal. During the coupling, the

following axis (slave) is synchronized via a defined motion profile to the position of

the leading axis (master). This can take place from any start position with a

continuous, jump free speed course. Upon decoupling, the slave leaves the

synchronous operation and is brought definedly to a standstill. The coupling or

decoupling can take place with a running or stationary master axis.

Loading...

Loading...