Parker EME

Setting up Compax3

192-121102 N04 June 2008 99

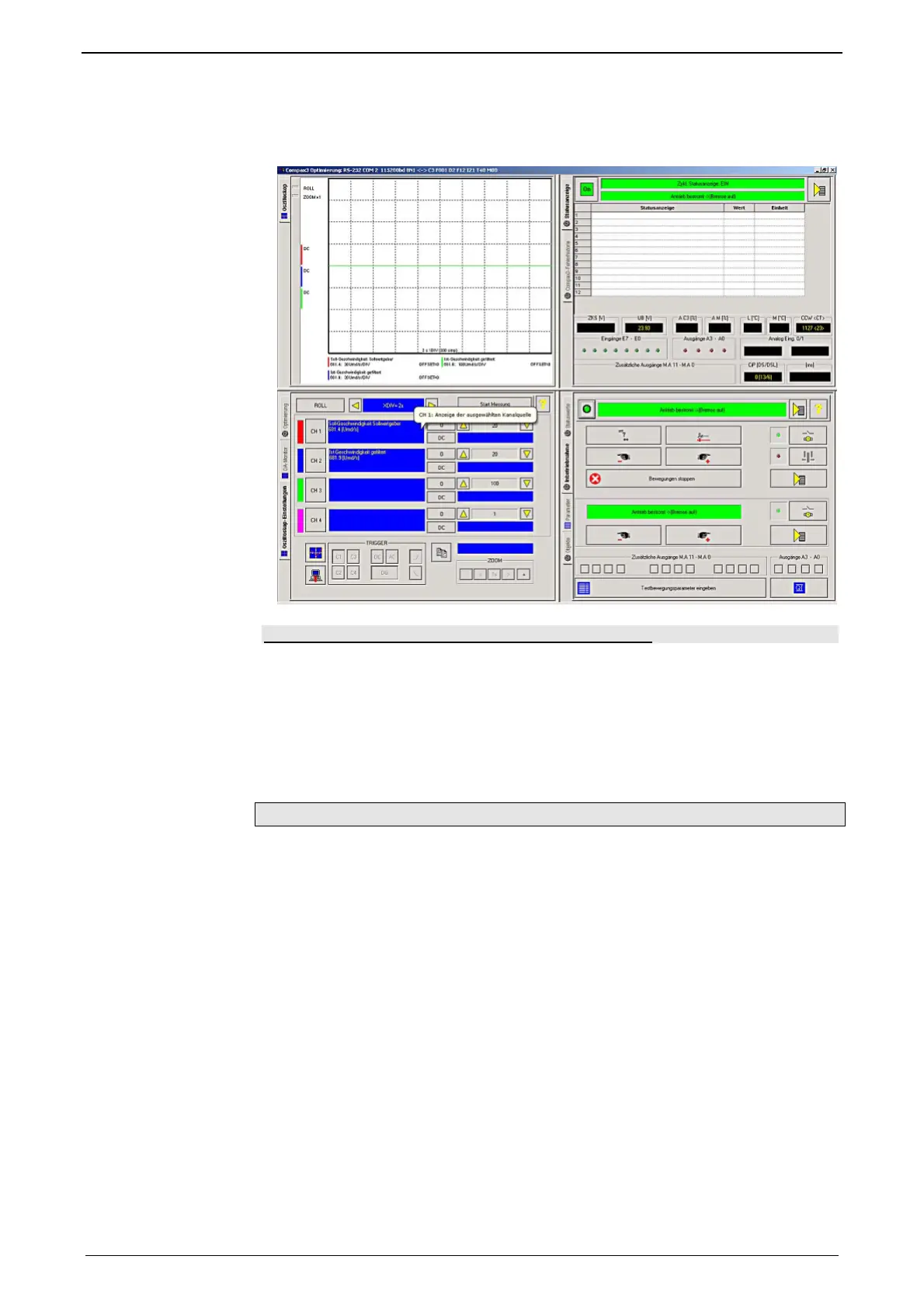

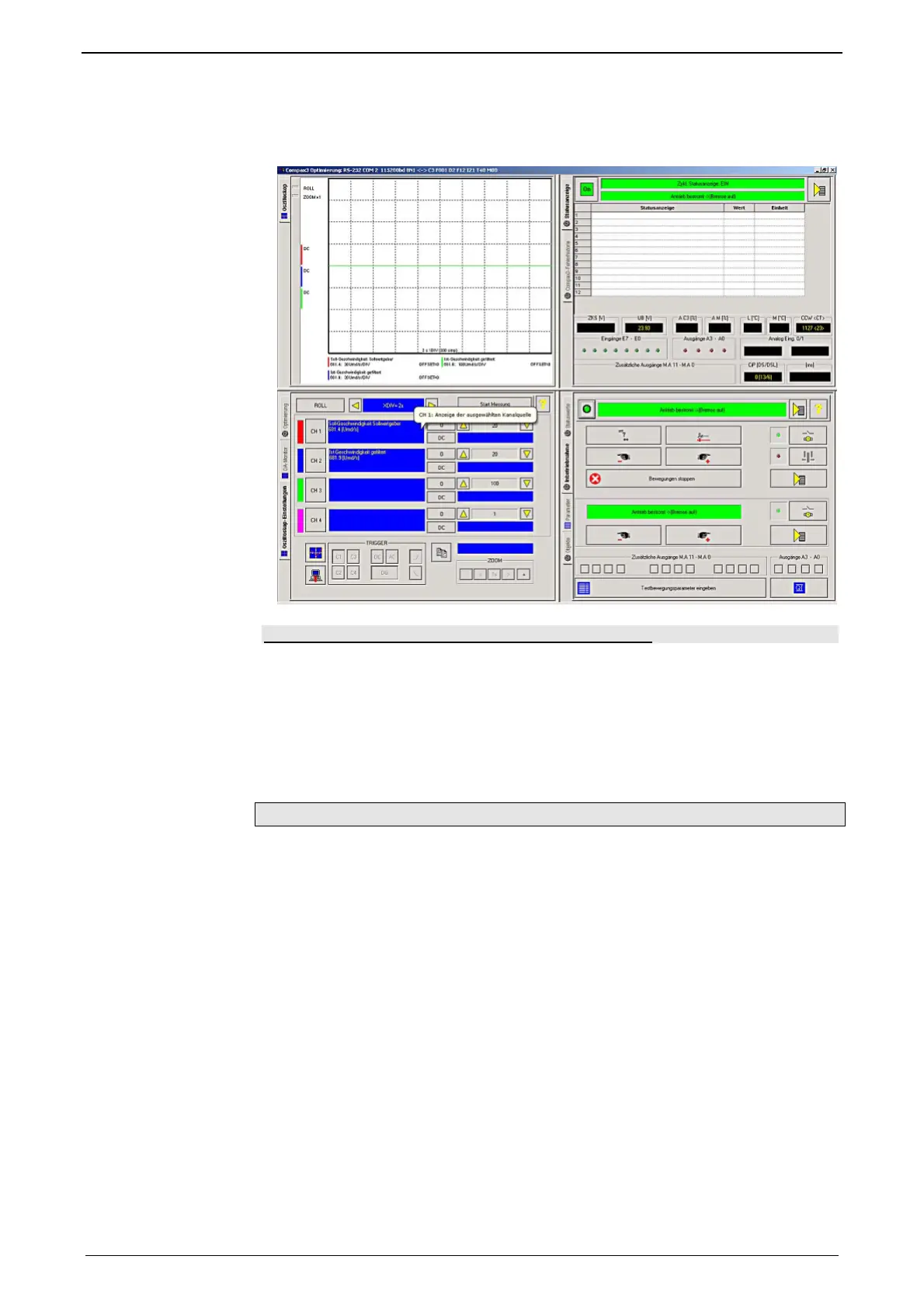

With the aid of the jog+/- function, the axis can be moved.

The setpoint generator- (681.4 or 681.2) and the actual speed (681.9 or 681.14)

must have the same sign (shown in the roll mode of the oscilloscope).

If this is not the case, there are two possible causes:

Wrong orientation of the position feedback system: The actual position can be

displayed in order to check this. Resolve by changing the feedback direction in

the configuration wizard or in the C3HydraulicsManager.

Incorrect wiring of the valves. The polarity can either be changed by changing the

wiring at the clamp or by inverting the output (Optimization Output Chain X

Inversion).

Compensation of non-linearities of the distance

Before the controller alignment, the non-linear components of the path should be

compensated with the aid of the Output Conditioning Chains. This helps to achieve

an improvement of the system behavior. There are several possibilities:

a) Pressure compensation

If pressure sensors are available, those can be used to compensate the differtial

pressure. This makes the control more robust with respect to variations in the

system pressure or the load.

Loading...

Loading...