Parker EME

Motion control

192-121102 N04 June 2008 175

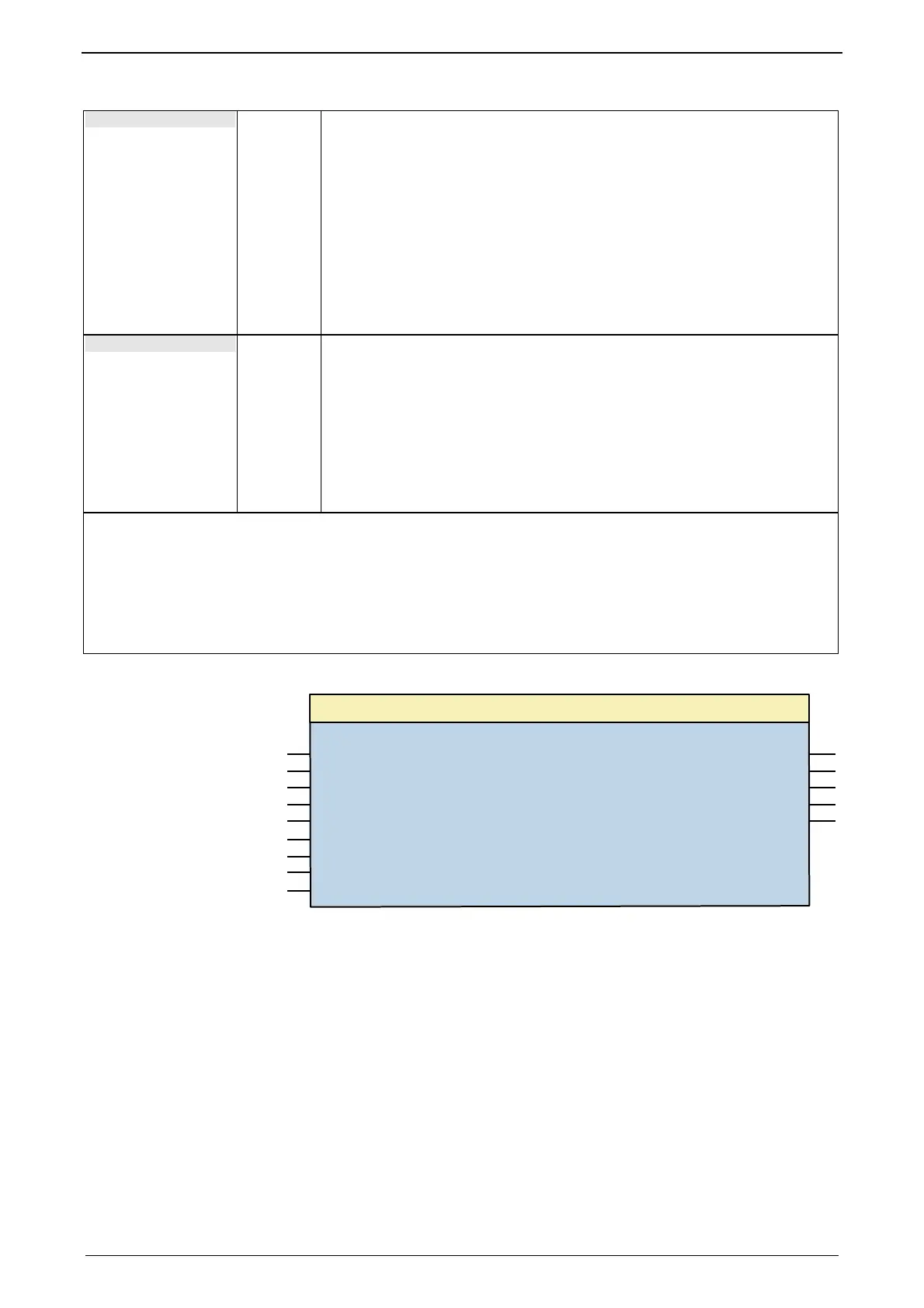

Status

INT Indicates how advanced the measurement is yet.

0 = waits for the start of the measurement with "Execute"

1 = Initialization of the measurement

2 = determination of the offset

(at which valve position does the axis no longer move

3 = Execution of the measurement

4 = Recovering of different settings

5 = Interpolation of the measurement values

6 = Memorizing the characteristic line in the flash

7 = Setting the Conditioning Chain Parameter to a new characeristic line

8 = Measurement terminated successfully, waiting for "Execute"

CurveID

INT States, under which ID the characteristic line was memorized.

The ID of the characteristic line is in object 24x3.2*

If you wish to switch back to characteristic lines set before, you should read the ID

of the characteristic line before activating the module.

Switching back of a characteristic line:

Select characteristiac line (for all connected Conditioning Chains)

24x3.2* = number of the characteristic line

Select characteristic line (for all connected Conditioning Chains)

24x3.1=1*

Note:

After successful measurement of the characteristic line, it is memorized in the same way and at the same

place as up to now the valve characteristic lines. As the memory utilized provides space for up to 8

characteristic lines, existing characteristic lines must not be deleted.

In order to activate the characteristic line for the control, the characteristic lines are activated by this

module with 24x3.1=1* at the conditioning chains which are connected to the measured axis.

* (x stands for the respective Conditioning Chain: x=0 for Chain 0, x=1 for Chain

1,...)

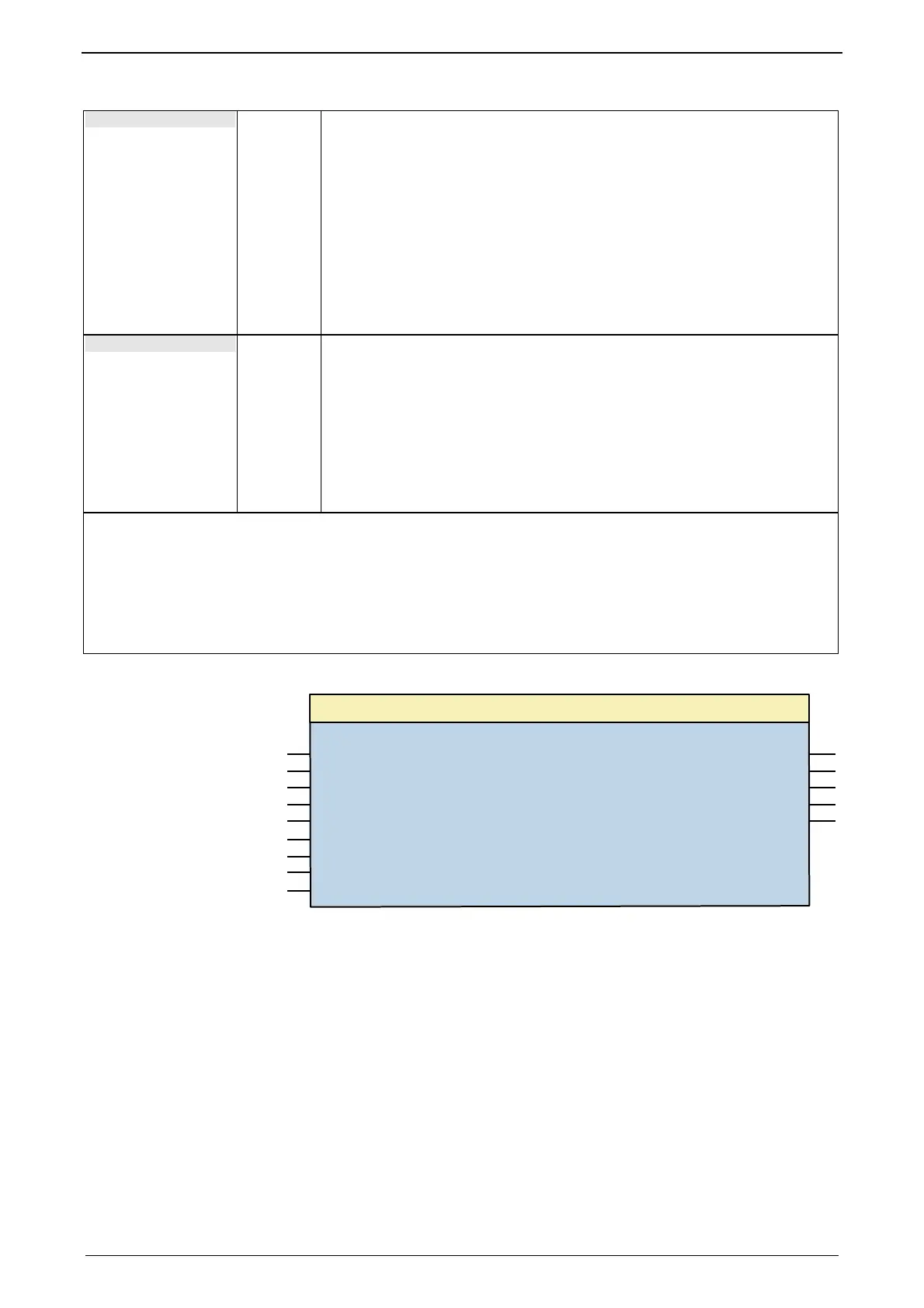

Execute : BOOL

Stop : BOOL

Number_of_Measuring_Points : INT

min_Position : REAL

max_Position : REAL

max_Velocity : REAL

Acceleration : DINT

Jerk : DINT

Axis : INT

C3_GetSystemFingerPrint

Done : BOOL

Error : BOOL

ErrorID : WORD

Status : INT

CurveID : IND

Loading...

Loading...