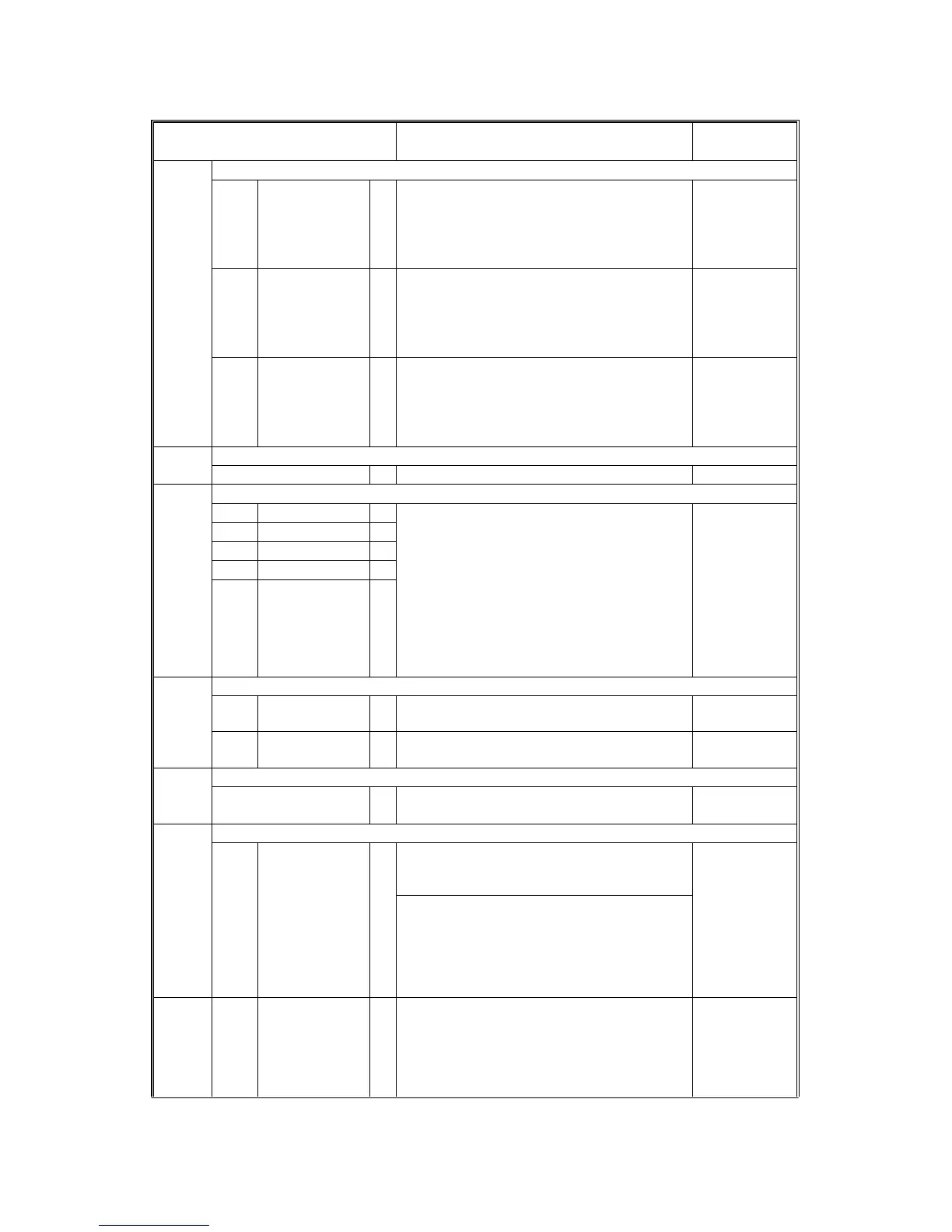

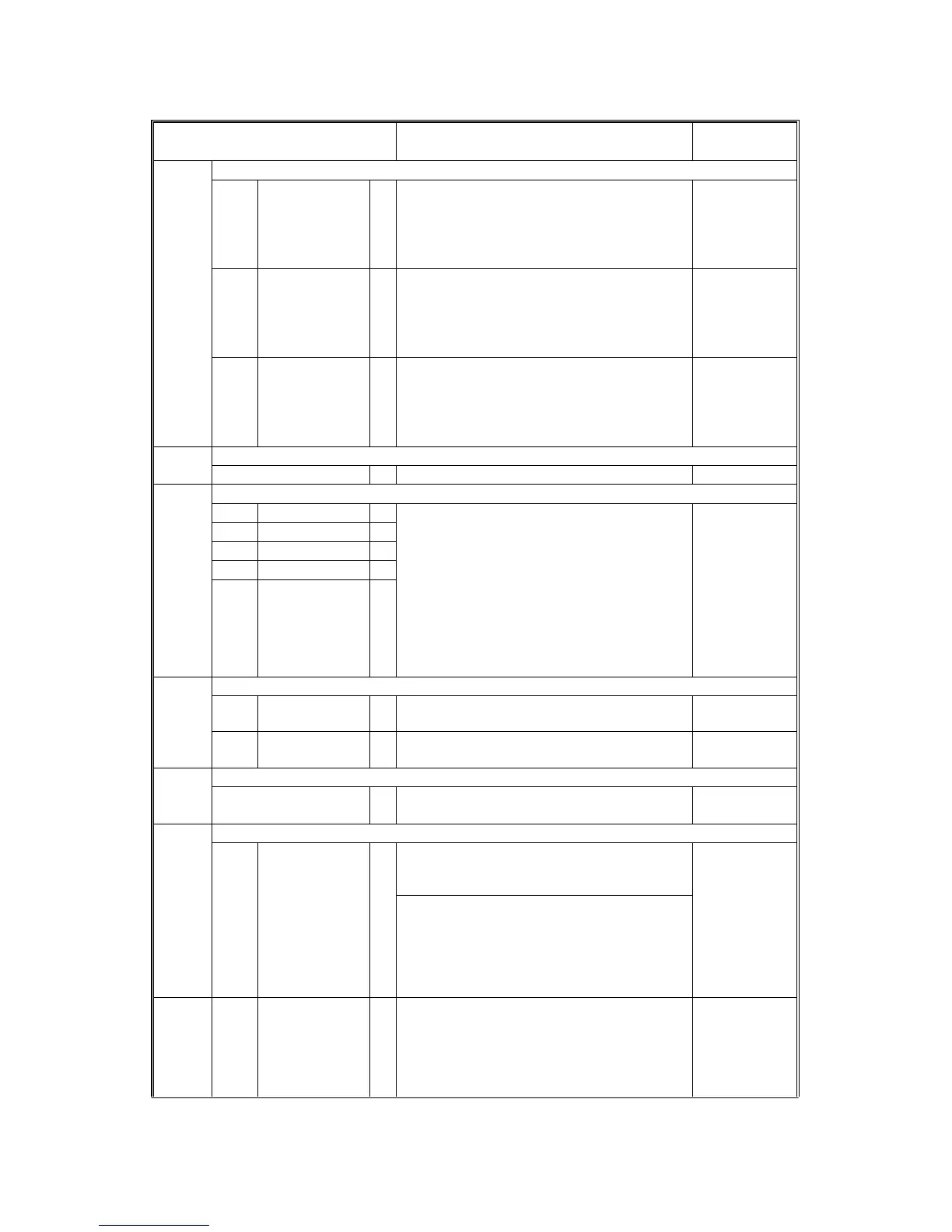

SERVICE PROGRAM MODE

4-12

A229 SM

Mode No.

(Class 1 , 2

&

3)

Function Settings

1-105 Fusing Temperature Adjustment

1 By-pass * Adjusts the fusing temperature for paper

fed from a by-pass tray.

Use the “

•

” key to toggle from + to - and

the Clear/Stop key to toggle from - to +

before entering the value.

170 ~ 200

1

°

C/step

185

°

C

2 OHP * Adjusts the fusing temperature for OHP

sheets fed from the by-pass feed unit.

Use the “

•

” key to toggle from + to - and

the Clear/Stop key to toggle from - to +

before entering the value.

+10 ~ -10

°

C

1

°

C/step

0 (165

°

C)

3 Thick Paper *

Adjusts the fusing temperature for thick

paper fed from the by-pass feed unit.

Use the “

•

” key to toggle from + to - and

the Clear/Stop key to toggle from - to +

before entering the value.

+5 ~ -10

°

C

1

°

C/step

0 (195

°

C)

1-106 Fusing Temperature Display

Displays the fusing temperature.

1-901 CPM Change for Thick Paper

1Tray 1 *

2Tray 2 *

3Tray 3 *

4Tray 4 *

5LCT *

Selects the copy speed when the fusing

temperature goes down when using thick

paper.

During a long copy run, the hot roller cools

down. This may cause poor fusing. To

prevent this, the copy speed can be

reduced when the temperature reaches a

certain level.

The 4th tray is used for the Japanese

version only.

0: None

1: 50 cpm -

165

°

C

2: 45 cpm -

175

°

C

1-904 By-pass Tray Paper Size Correction

1 Minimum Size *

Calibrates the minimum paper width

position of the sensor (100 mm).

Start

2Maximum Size*

Calibrates the maximum paper width

position of the sensor (A4 sideways).

Start

1-905 Thick Paper Mode - By-pass Table

* Selects the by-pass feed clutch on mode

for thick paper mode.

ON: Twice

OFF: Once

2-001 Charge Corona Bias Adjustment

1 Image Area * Adjusts the voltage applied to the grid plate

during copying when auto process control

is

off

.

Normally, there is no need to adjust this. If

there is an ID or TD sensor problem, the

machine goes into fixed toner supply

mode.

After replacing the drum or charge corona

wire, change this value to the default.

-600 ~ -1300

10 V/step

-1000 V

2-001 2 ID Sensor

Pattern

*

Adjusts the voltage applied to the grid plate

when making the ID sensor pattern.

Normally, there is no need to adjust this.. If

the user wants high density copies, the

sensor pattern must be lighter, so this voltage

must be a higher negative voltage.

-600 ~ -1300

10 V/step

-650 V

Rev. 12/15/98

Loading...

Loading...