LASER EXPOSURE

2-43

SM A229

Detailed

Descriptions

2.4 LASER EXPOSURE

2.4.1 OVERVIEW

This machine uses two laser diodes to produce electrostatic images on an OPC

drum. The laser diode unit converts image data from the SBICU board into laser

pulses, and the optical components direct these pulses to the drum.

Exposure of the drum by the laser beam creates the latent image. The laser beam

makes the main scan while drum rotation controls the sub scan.

The combined strength of both beams is 0.5 mW on the drum surface at a

wavelength of 780 nm.

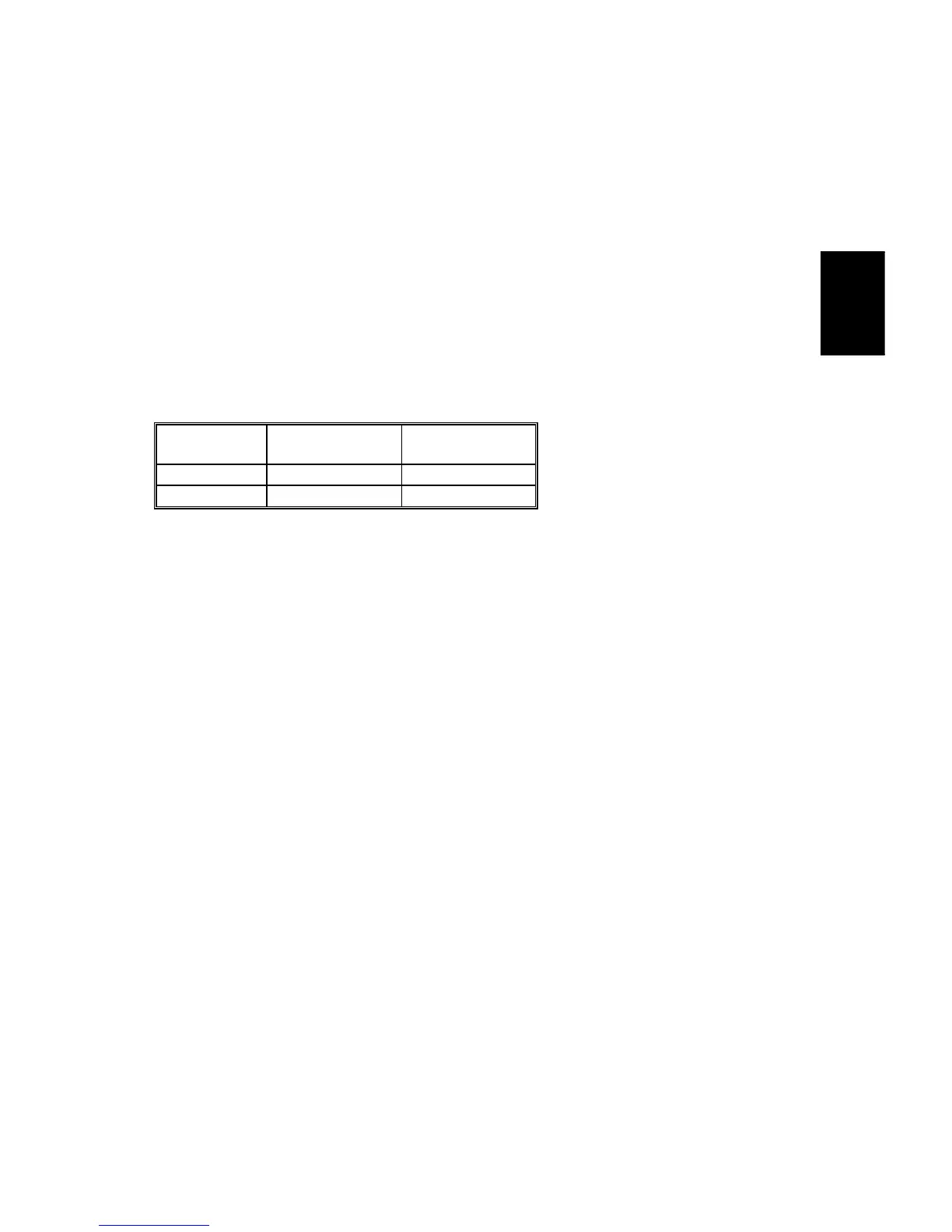

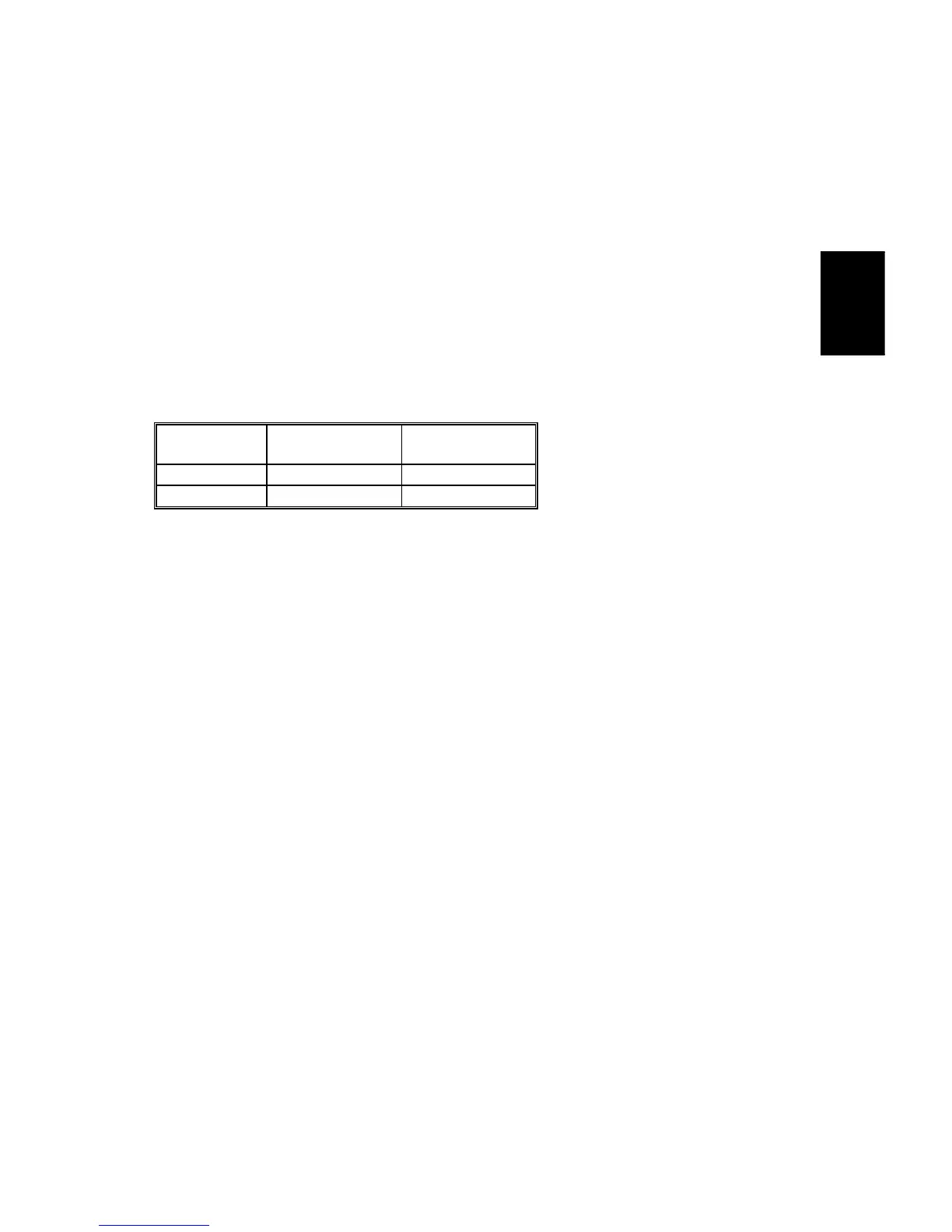

The polygon motor speed is as follows.

Resolution Modes

Motor Speed

(rpm)

400 dpi Copy, Printer Approx. 25984

600 dpi Printer Approx. 38976

There are up to 16 image density levels for each pixel. To realize this, this machine

uses a form of pulse width modulation. In this machine, pulse width modulation

consists of the following processes:

•

Laser diode pulse positioning

•

Laser diode power/pulse width modulation

Laser diode power and pulse width modulation is done by the laser diode drive

board (LDDR). Briefly, the width of the laser pulse for a pixel depends on the output

level (from 0 to 15) required for the pixel.

This machine can also change the laser pulse position (at the left side of the pixel,

at the center, or at the right side) automatically, depending on the location of the

image pixel so that the edges of characters and lines become cleaner. There is no

SP mode adjustment for this, unlike in some earlier models.

Loading...

Loading...