Atmospheric Single-Arm Robot Manual

4000-0016 Rev A

95

Alternatively, you can send commands in Terminal mode from either a

Teach Pendant or EQT 32. If you send the commands from the Teach

Pendant, the response from the controller is displayed in hexadecimal

format.

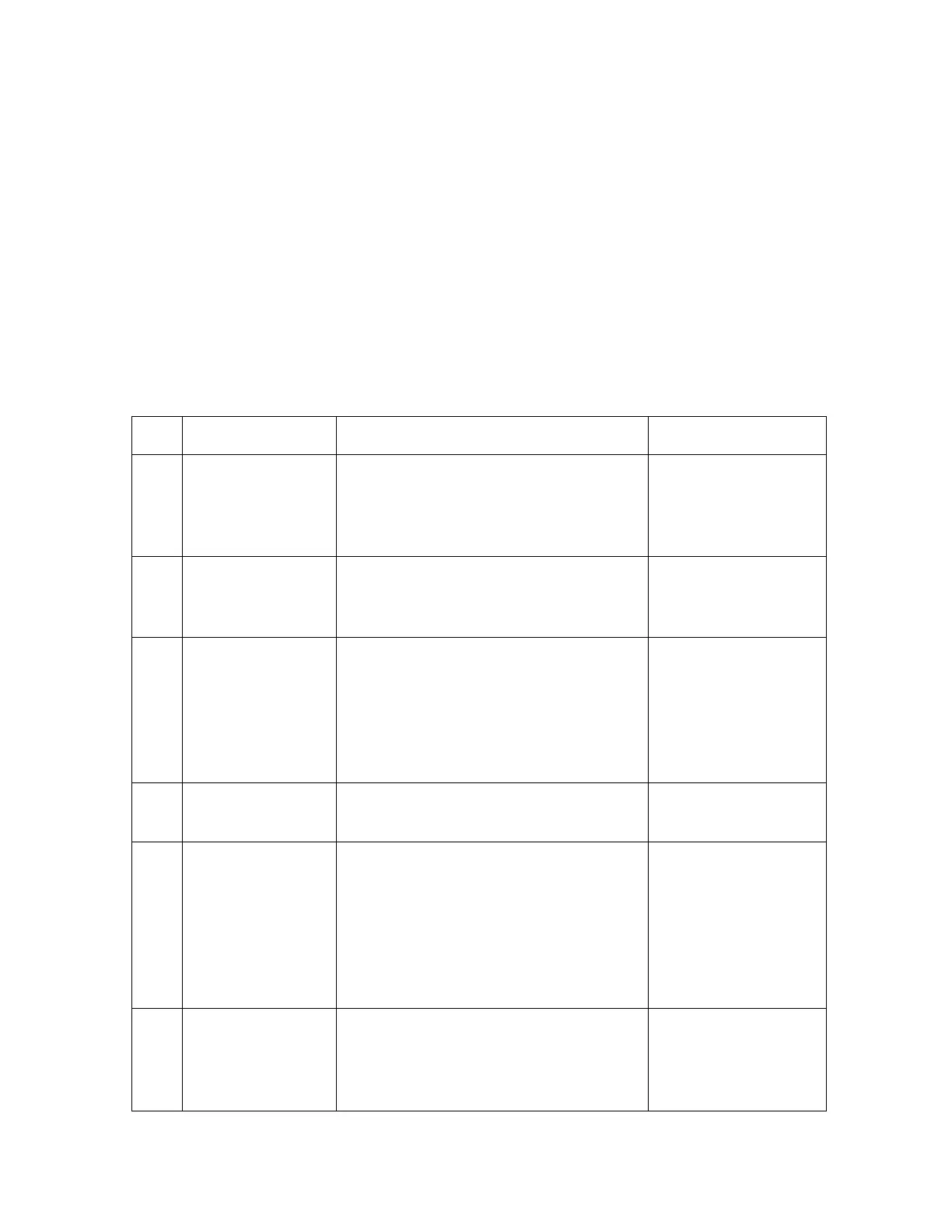

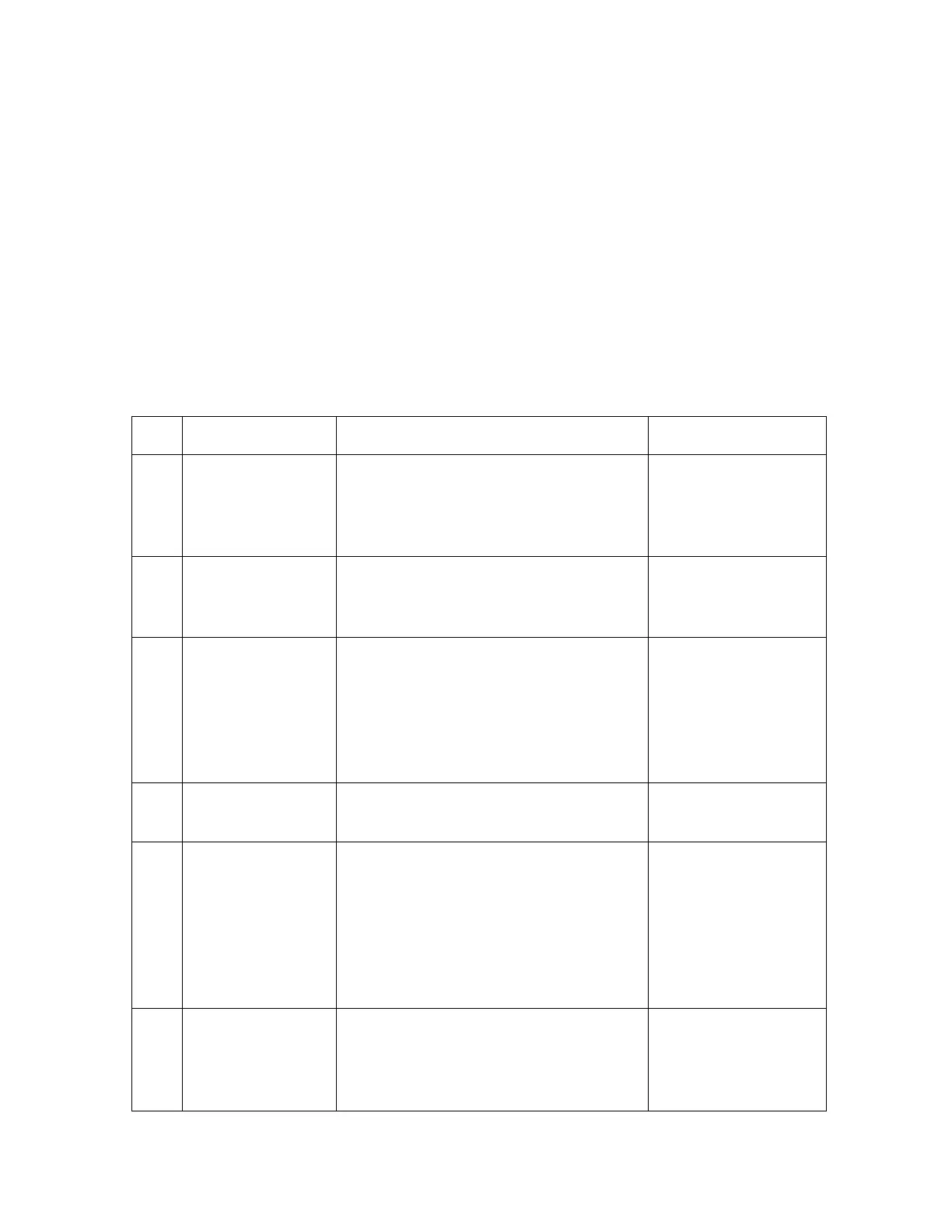

Cause and Recovery for STAT Messages

The setting of each status bit is caused by one or more reasons. Sometimes

the cause is fatal and needs immediate action to recover, and sometimes

the cause is harmless and does not require any direct action. The

following table lists the probable cause of the problem and suggested

recovery for each of the 16 status bits.

Bit Message Cause Recovery

0 Previous

command not

executed

The command cannot be executed for

the current condition. For example, a

SVON command cannot execute while

axes are moving. Also see Bit 2.

Review the

command and the

conditions.

1 Previous

command invalid

The command is unknown or has

invalid syntax. When Bit 1 is set to 1,

Bit 0 is also set to 1.

Check command

syntax.

2 Vacuum sensor is

activated

Vacuum sensor is on; an object is

detected. When Bit 2 is set to 1, Bit 3

should be 1 (vacuum switch is on). If

Bit 2 is 1 regardless of presence of

object or status of Bit 3, the vacuum

sensor is too sensitive.

Adjust the vacuum

sensor.

3 Vacuum switch is

ON

A normal condition. For example, a

GET or PUT command turns Bit 3 on.

None.

4 Motor error on

one or more axes

One or more axes have a position error

condition. Excessive force has been

applied to the force generated by the

motor. An obstacle might be in the

robot path. Or, the Servo Error Limit

(ER) is too small. Setting Bit 4 to 1

sets Bit 10 to 1.

Clear the obstacle,

send the SVON

command, and

continue. If ER is too

small (usually about

100-200), change the

setup and increase.

5 One or more limit

switches are

triggered

There are two limit switches (positive

and negative) for the T and Z axes. The

RLS command shows detailed

information on limit switches.

Send the RLS

command to

determine which

limit switches are on

Loading...

Loading...