Atmospheric Single-Arm Robot Manual

4000-0016 Rev A

104

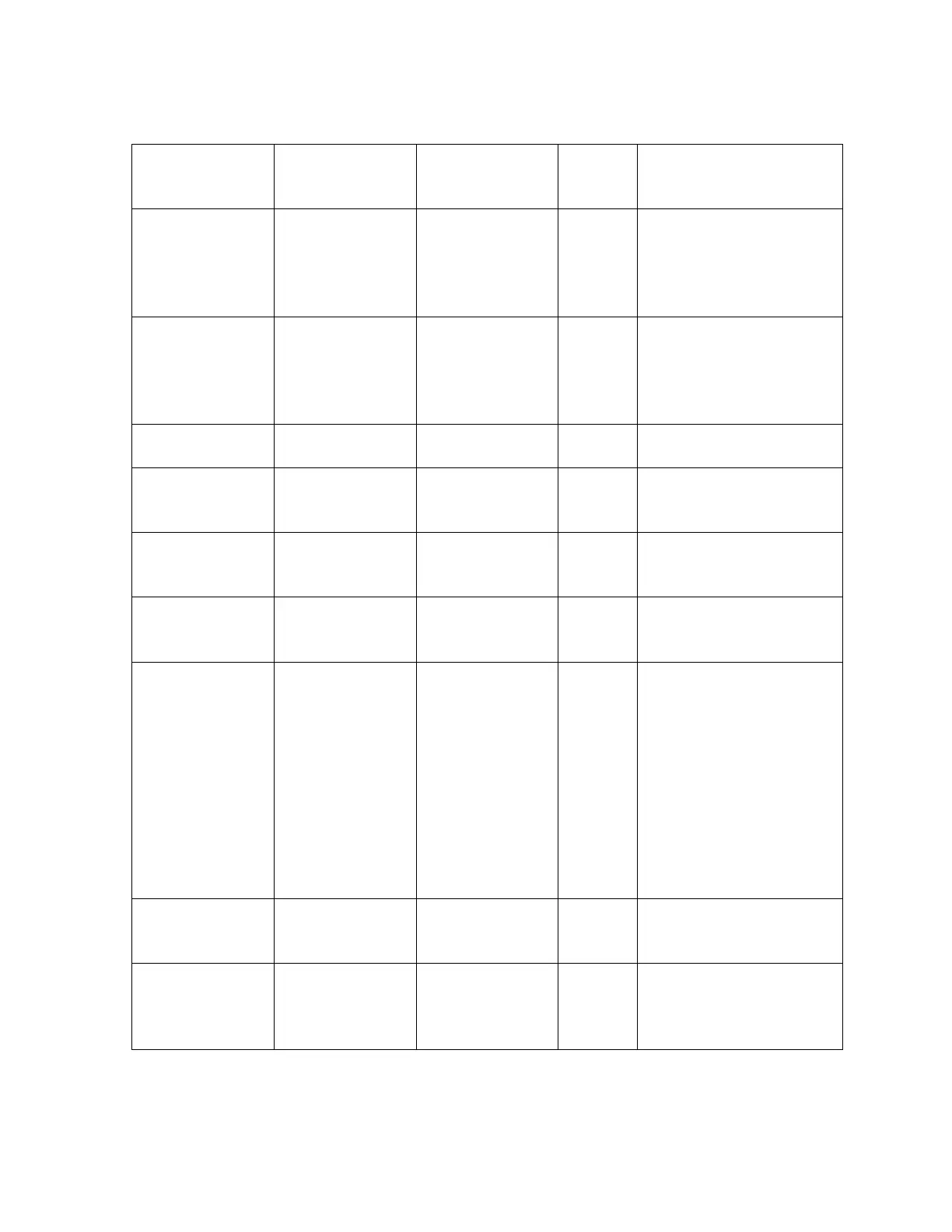

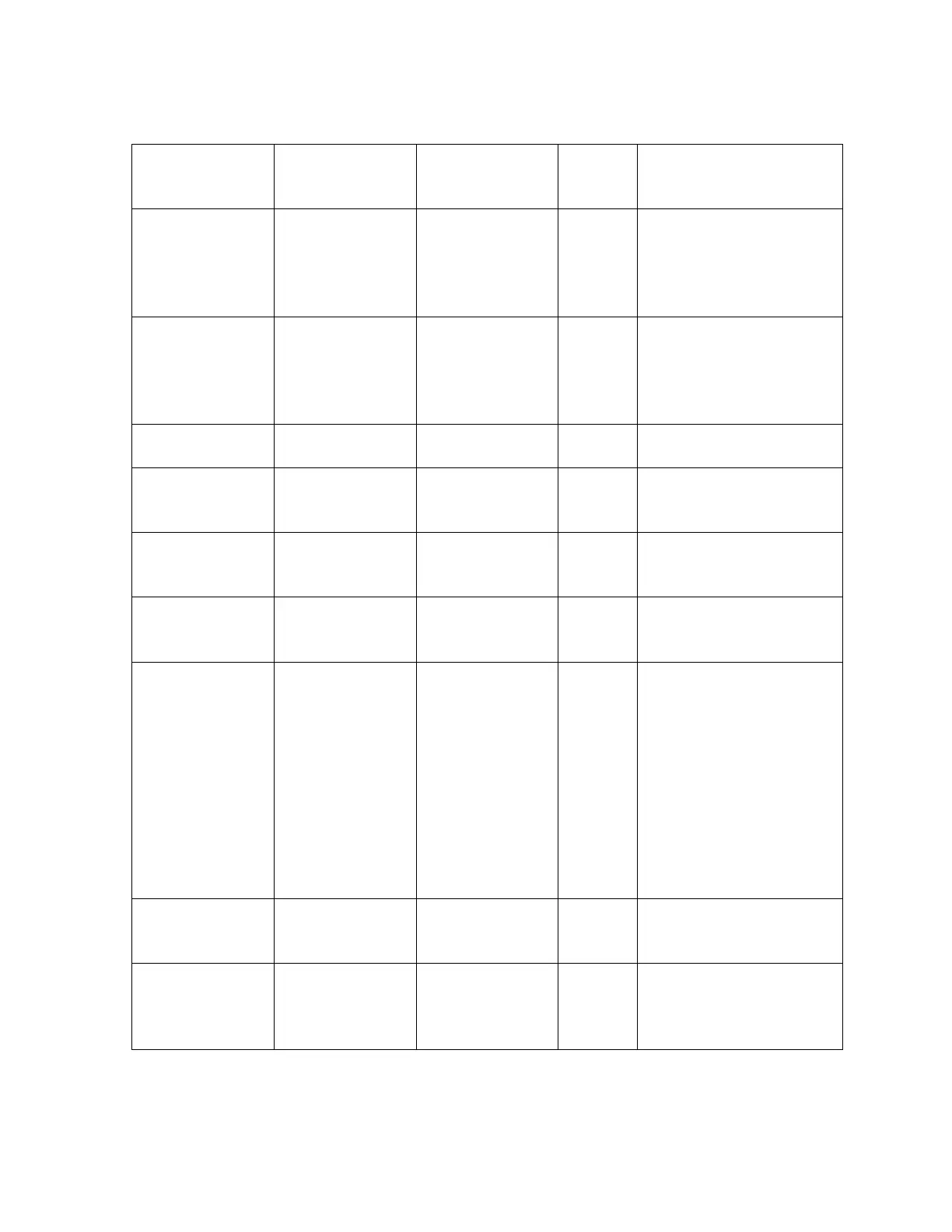

False -positive

signal generated

by limit switch

Bits 4,

5, and

10

Send RLS to determine

which axis. Replace

limit switch assembly.

Axis stops when

it comes in

contact with an

object, such as a

wafer

Mechanical

friction is too

high

Bits 4

and 10

Check all transmissions

along the axis. Make

sure belts are not too

tight and bearings move

smoothly.

Robot stops

when it comes

in contact with

an object, such

as a wafer

Excessive

electrostatic

discharge or

EMI/RFI to

robot

Bit 14 Re-route each-grounding

and proper shielding.

Robot hits the

object

Bits 4

and 10

Re-teach robot.

Robot not

repeatable

Axis position

drifting over

time

Worn-out belts Inspect belts, and replace

if necessary.

Loose

transmission

shaft

Inspect shaft by rotating

pulley manually while

servo is on.

Bad Encoder Use oscilloscope to test

the Encoder output

signal .

Axis position

slightly different

from the last

time stations

were taught.

The difference

is consistent

from one station

to another.

Slipped belt(s) Inspect belts for loose

adjustment. Perform

Diagnostic Step 8 to

ensure the distance from

the home switch and

encoder index is within

the allowable range. For

the R-axis, also perform

Step 9 to re-calibrate the

Home offset. Then re-

teach the stations.

Encoder index

set too close to

home switch

Reset index.

Axis position

different after

every HOME

sequence

Intermittent

limit switch

problem

Bit 5 Send RLS to determine

which axis. Replace

limit switch assembly.

Loading...

Loading...