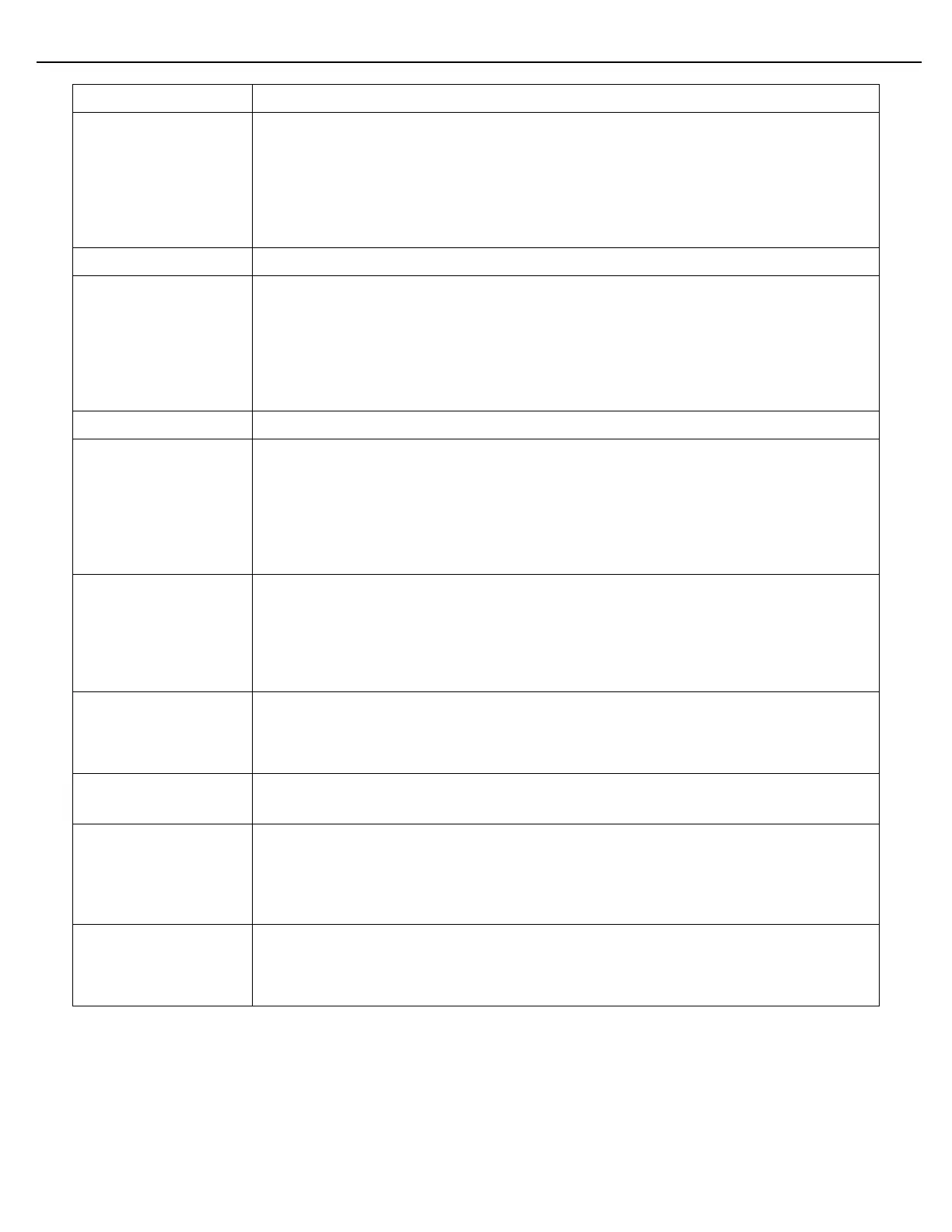

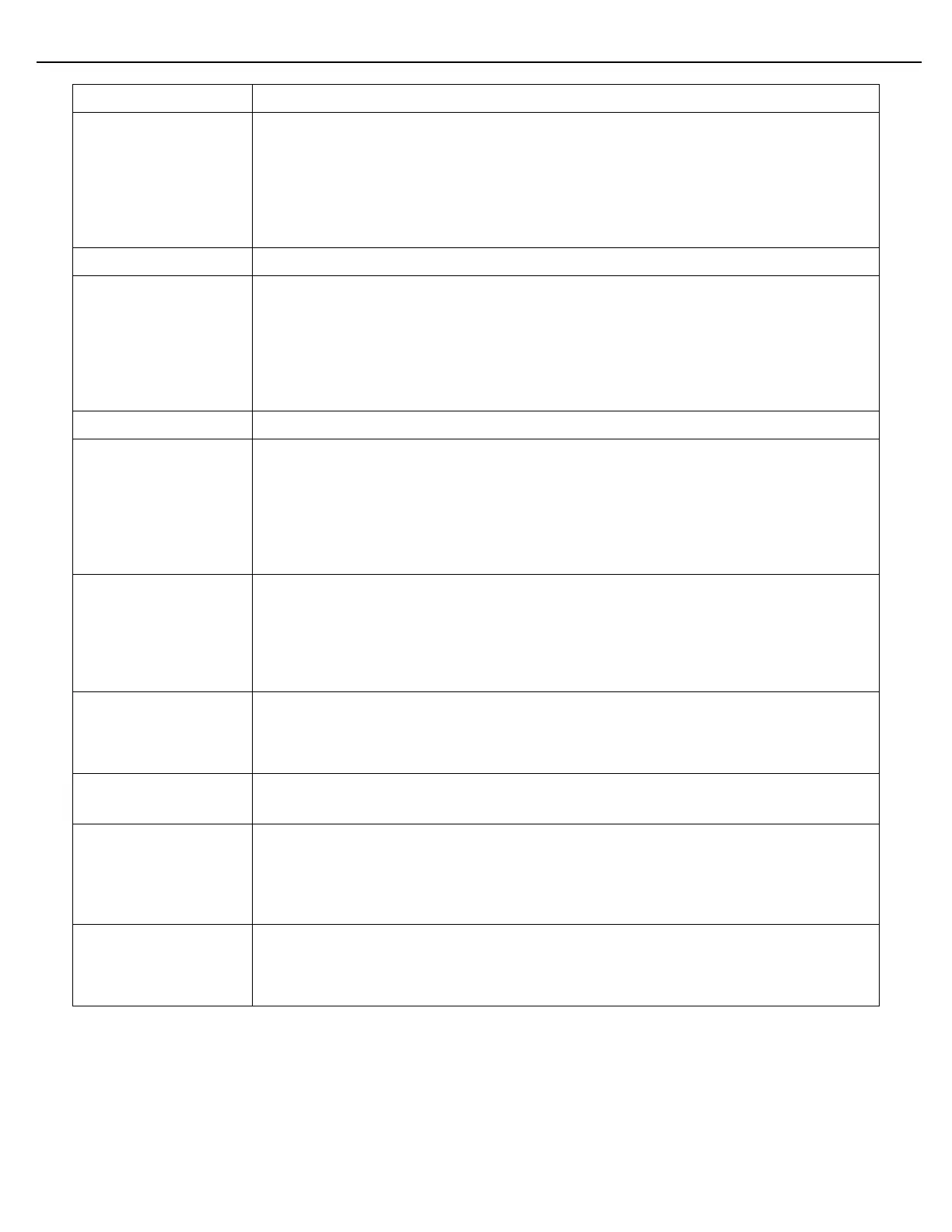

Chapter 4 – General Configuration

Firmware Version 3/4.31.37

Enter a volume that will trigger the beginning of the First Stage Trip phase. The First

Stage Trip phase will begin when the remaining preset volume is equal to the value

specified in this parameter. The First Stage Trip phase is the initial reduction from the

High Flow rate to a no flow condition. When the First Stage Trip Volume is reached, the

flow control valve will reduce the flow rate from the High Flow Rate to a flow rate

specified by the First Stage Flow Rate parameter. The First Stage Trip phase will end

when the Second Stage Trip Volume is reached.

Enter the target flow rate for the First Stage Flow Rate.

Enter a volume that will trigger the beginning of the Second Stage Trip phase. The

Second Stage Trip phase will begin when the remaining preset volume is equal to the

value specified in this parameter. The Second Stage Trip phase is the second in a series

of adjustments from the High Flow rate to a no flow condition. When the Second Trip

Volume is reached, the flow control valve will reduce the flow rate from the First Stage

Flow Rate to a flow rate specified by the Second Stage Flow Rate parameter. The

Second Stage Trip phase will end when the Final Trip Phase is reached.

Enter the target flow rate for the Second Stage Flow Rate.

Enter a volume that will compensate for the amount of time it takes the control valve to

close from the Second Stage Trip phase, as the preset quantity is reached. Before

entering a value for this parameter, adjust the closing speed of the control valve to the

optimum setting, using procedures provided by the valve's manufacturer. This parameter

will command the valve to close a little earlier to compensate for small, consistent over

deliveries. Or it can be commanded to close a little later to compensate for small,

consistent under deliveries. This adjustment is made on a volumetric basis

The Final Trip Stage is the last phase of delivery where product flow is authorized. The

Final Trip Max Time parameter establishes the length of time, in milliseconds, that this

phase is active. When the time specified in this parameter has elapsed, flow must be

completely stopped. If there is no flow when the time expires, the preset will transition to

the Idle state. If flow is still detected past this period, the Overrun Alarm will activate if

the Overrun Alarm Volume has been exceeded.

Enable this parameter to prevent the MultiLoad II from automatically adjusting the Final

Trip Volume parameter. When this parameter is enabled, the MultiLoad II will analyze

the closing performance of the control valve and make adjustments to the Final Trip

Volume as necessary.

If this value is non-zero and a tank associated with the component has a High High

Level alarm or a Low Low Level alarm loading will be inhibited.

If this component is to have the recipe percentage under W&M protection, set this value

to the W&M accepted value. When this value is non-zero, the Component Recipe

Percentage MUST be equal to the W&M Recipe Percentage or all attempts to authorize

a batch will be denied displaying a message of “W&M Required Component Pct Not

Correct”.

Specify the volume of Unauthorized Flow that will have to accumulate before an

Unauthorized Flow Alarm is raised. Unauthorized Flow occurs when the flow meter

senses the movement of product when the component has not been authorized for

delivery.

Loading...

Loading...