Chapter 4 – General Configuration

Firmware Version 3/4.31.37

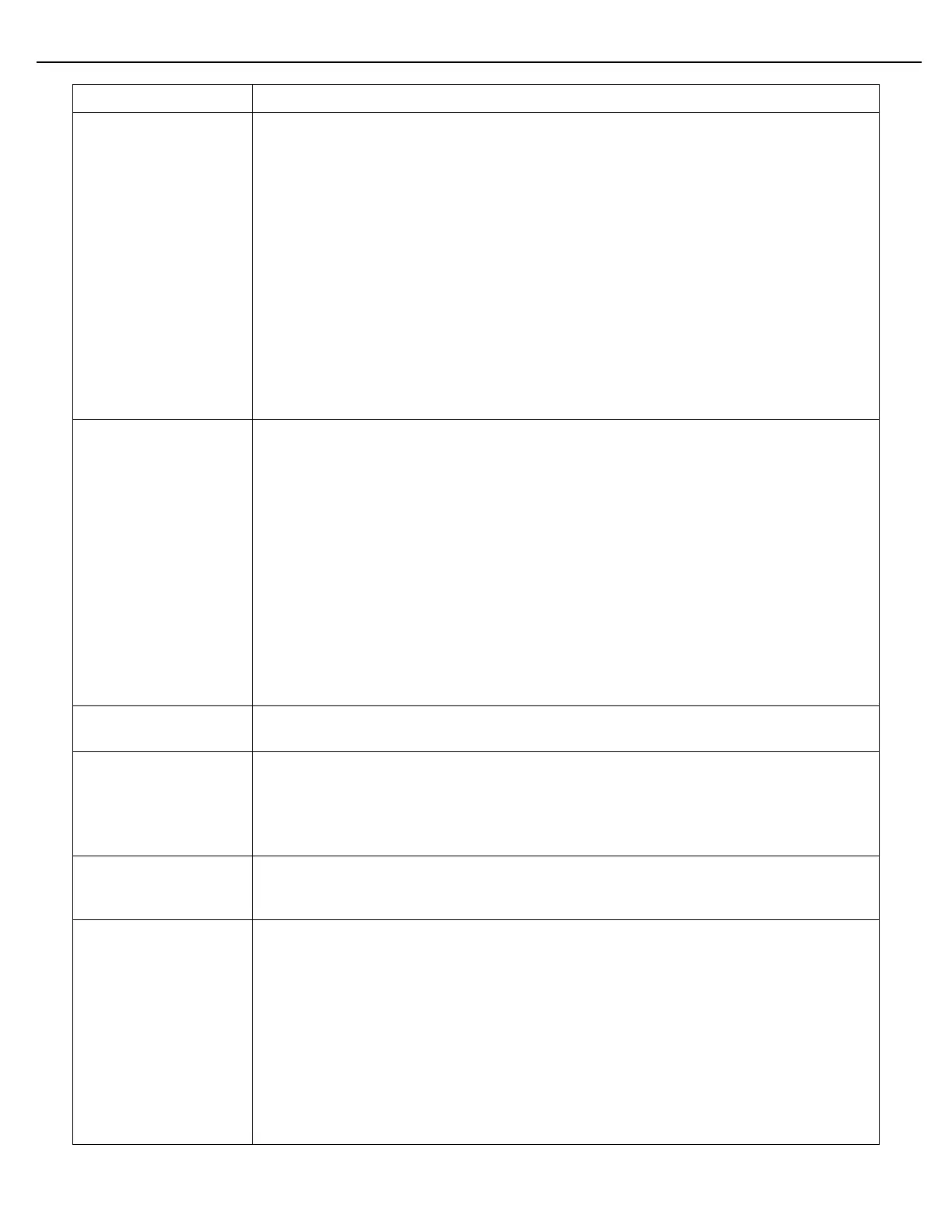

This parameter needs to be configured when the API Table ASTM D1555-09 is chosen.

Selecting the Aromatic Hydrocarbon is needed for proper calculation of the CTL factor.

Also for the weight calculation of these products it is needed to enter a default relative

density. If the value is unknown please use the ASTM standard values shown below.

Product DensityVaccum DensityAir

BENZENE 7.3751 7.3662

CUMENE 7.2219 7.2130

CYCLOHEXANE 6.5315 6.5225

ETHYLBENZENE 7.2669 7.2580

STYRENE 7.5926 7.5837

TOLUENE 7.2685 7.2596

M-XYLENE 7.2425 7.2336

O-XYLENE 7.3723 7.3634

P-XYLENE 7.2151 7.2062

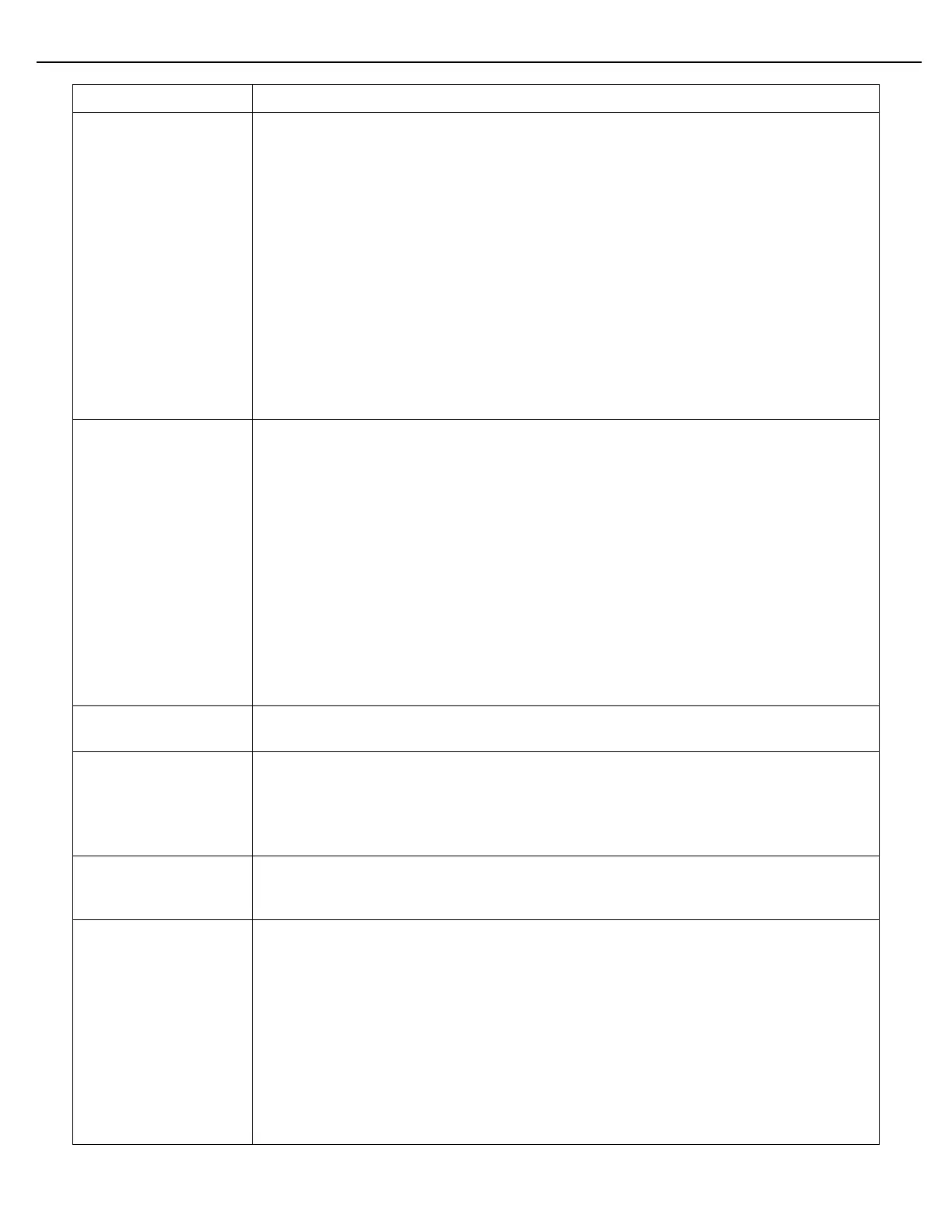

This parameter enables an output pulse that is representative of the volume delivered

through a preset’s flow meter.

For FCMs and I/O boards with firmware 035 and earlier, the port setting must always be

set to 1 for FCMs and 10 for I/O boards.

For FCMs and I/O boards with firmware 026 and later, the port setting can be 0-5 for

FCMs, and 10-12 for I/O boards.

For FCMs and I/O boards with firmware 038 and later, support dual pulse outputs. Enable

dual pulse output by configuring the “Invert” state on this port. This port will be the leading

pulse. The trailing pulse will be the next contiguous port (0/1, ½, 2/3, ¾, 4/5, 10/11, 11/12)

on the FCM or I/O board.

Notes:

Single Output Pulse Limited to 500 Hz Max.

Dual Output Pulse Limited to 250 Hz Max.

Output pulses are NOT real time and delayed up to 1 second from acquisition.

A factor can be applied to the pulse output to achieve the desired pulse resolution. The

pulse resolution can be configured from 0.001 to 50.000 pulses per unit volume or mass.

When NET, output pulses will represent net volumes. CTL and/or CPL must be

configured before pulses representing net volume can be realized. The output pulses

will represent gross volumes when this parameter is set to GROSS.

When the parameter is set to MASS, output will be Mass. It is necessary that density

and UOM type of Mass are populated.

Permits selection of a port that will provide an output signal to close a component’s block

valve. This feature is provided for block valves that require separate opening and

closing signals.

Block Valve Status FCM# parameter allows the selection of a port that will receive an

input signal. The input signal will represent the state of the component block valve,

indicating whether it is open or closed. When the block valve is closed, an external

contact attached to the valve will close, applying a status signal to the input. When the

block valve is open, the external contact will also be open, removing the status signal

from the input. When the block valve has been commanded to open, the absence of a

signal at the input will indicate that the valve has opened. If the “closed” signal is still

present after the Block Valve Open Delay time has elapsed, a block valve failure alarm

will be issued. When the block valve has been commanded to close, the presence of

the status signal at the input will indicate that the valve has closed. If the “closed” signal

has not been detected by the time the Block Valve Close Delay time has elapsed, a

block valve failure alarm will be issued.

Loading...

Loading...