Chapter 6 – Additive Control

Firmware Version 3/4.31.37

Choose the port that will serve as the additive injection (output) signal for the selected

additive. Possible choices are 0-3 (0-1 on SMP). This port choice also automatically

chooses a port to serve as either the additive meter input or the additive feedback

signal.

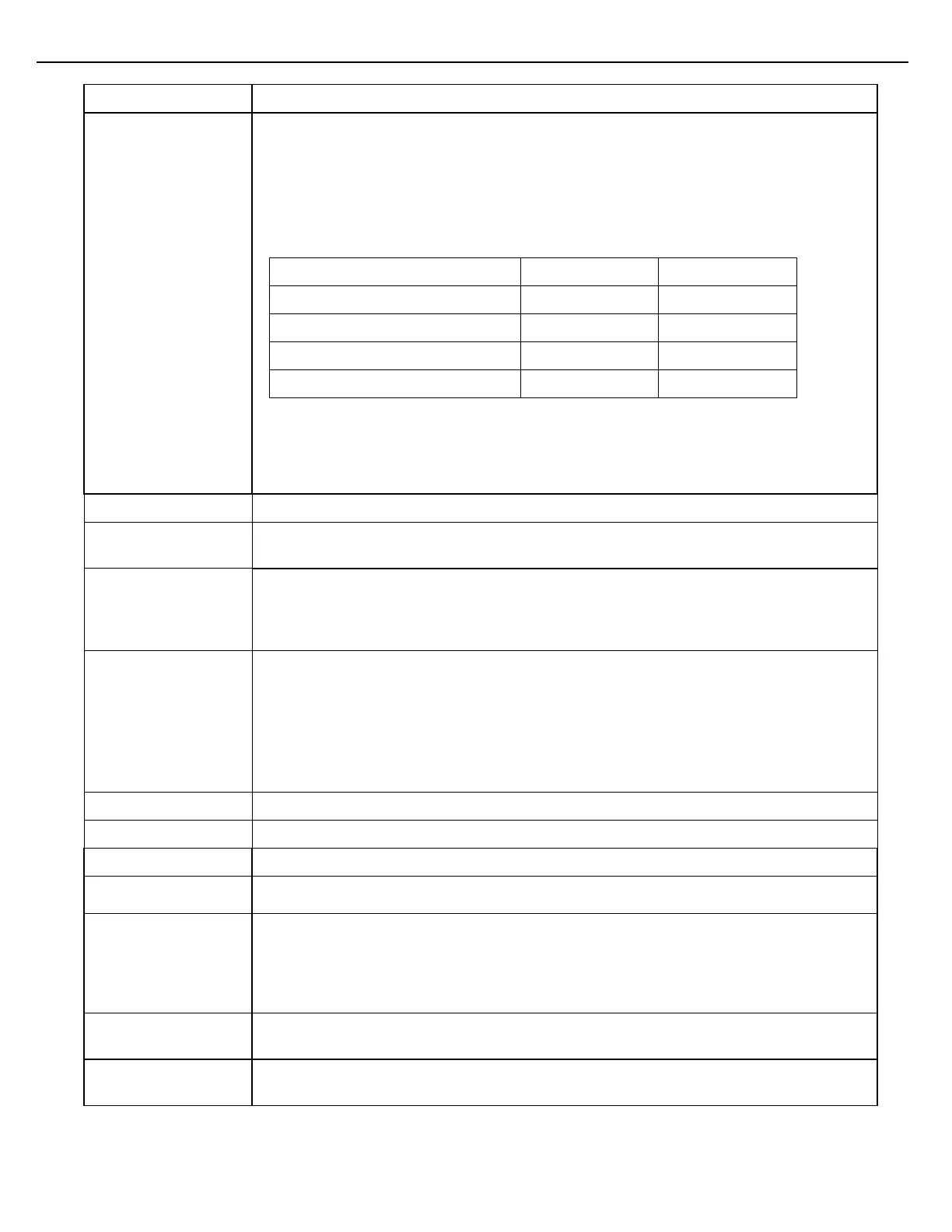

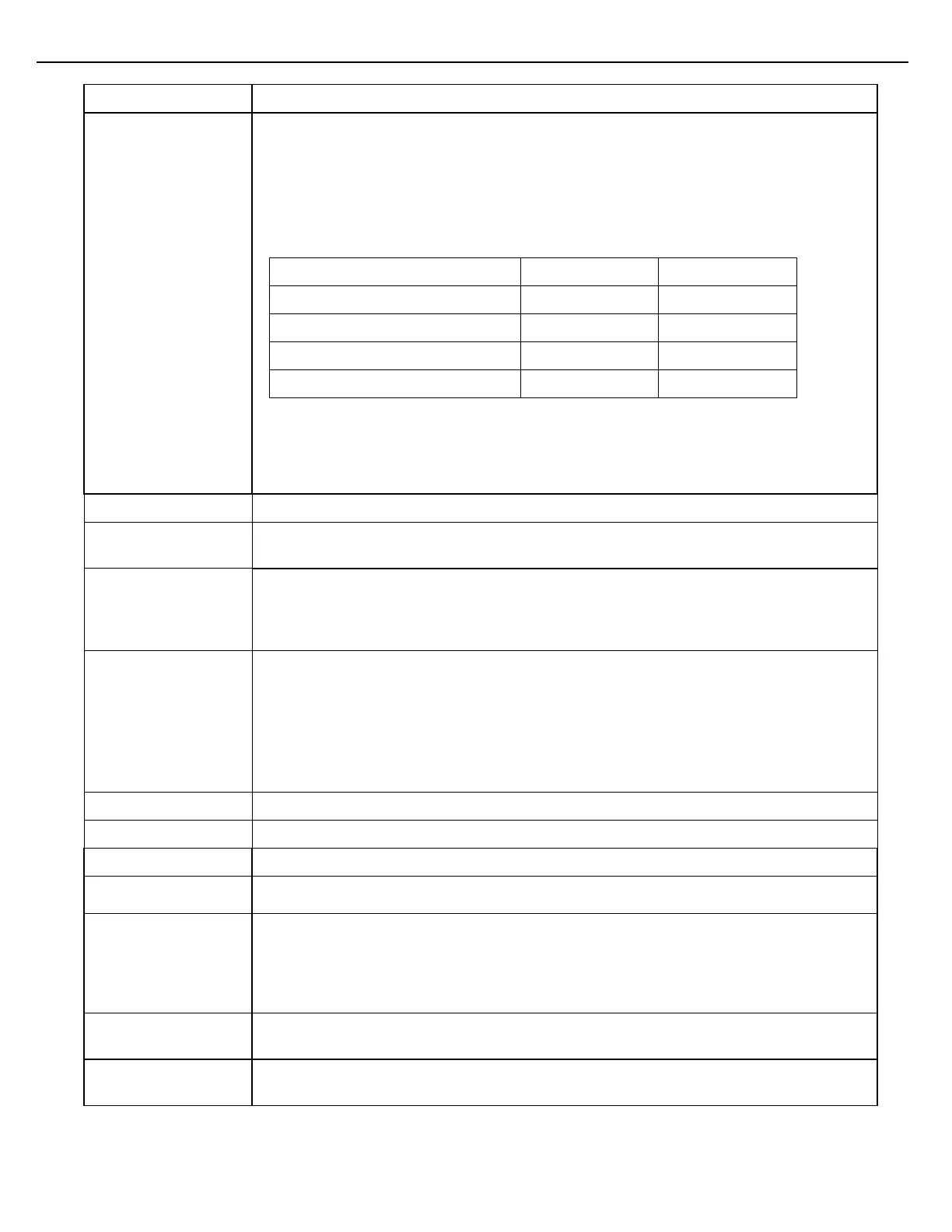

The following list shows which additive meter input/injector feedback input corresponds

to what additive port.

Additive Port Additive Meter/Injector Feedback Input

Injector #3 (Excluding SMP)

Injector #4 (Excluding SMP)

For example, if Additive Port #0 is chosen, the additive solenoid will be energized by the

port 0 output and the additive meter input signal will be expected at port 7. If a

calibrated cylinder is used with no additive meter, a feedback signal can be sent to port

7 to verify that the piston has completed the injection cycle.

Enables select additive parameters for this additive to be under W&M control.

Enable this parameter if the additive block valve is upstream of the injector. When

enabled, the additive block valve will be opened during additive calibration.

Controls how additive recipe should be calculated, apart from the preset Delivery Type.

If set to GROSS, the target volume will be based off of the gross volume delivered. If set

to NET, the target volume will be based off of the net volume delivered. If set to MASS,

the target volume will be based off of the mass amount delivered.

Choose the type of additive control to use, which is one of:

SolnMtr – Solenoid with meter

PstnNFB – Piston with normal feedback

PstnIFC – Piston with inverted feedback

Pstn – Piston with no feedback

AnlgMtr – Analog valve with meter with PID control

Proportional gain for PID loop (only applies to analog valve additive type)

Integral gain for PID loop (only applies to analog valve additive type)

Derivative term for PID loop (only applies to analog valve additive type)

This parameter will set the loop current when the additive control is IDLE. This is only

related to a 4-20mA additive type.

There are 3 Additive Modes:

StrBtch: Injection of the additive starts at the start of the batch.

StrHigh: Injection of the additive starts when the preset goes to High Flow.

StrVol: Injection of the additive starts when the start volume or restart volume is

exceeded.

This is the start volume when the additive will try to injection again. This parameter is

only used when Additive Mode StrVol is selected.

This is the restart volume when the additive will try to injection again. This parameter is

only used when Additive Mode StrVol is selected.

Loading...

Loading...