Ground drive and Rear Axle Service 9980 Self-Propelled Peanut Combine

Each time a rear wheel is removed, torque the

wheel bolts to the specifications below. After

one hour of operation torque wheel blots again

to specification.

Wheel bolts (non-powered………….315 N*m

axles) – Torque (dry) 232 lb-

ft)

Wheel Bolts (powered………200 N*m + ¼ turn

Axles) – Torque (dry) (150 lb-ft + ¼

turn)

Refer to decal on tire for proper torque

sequence.

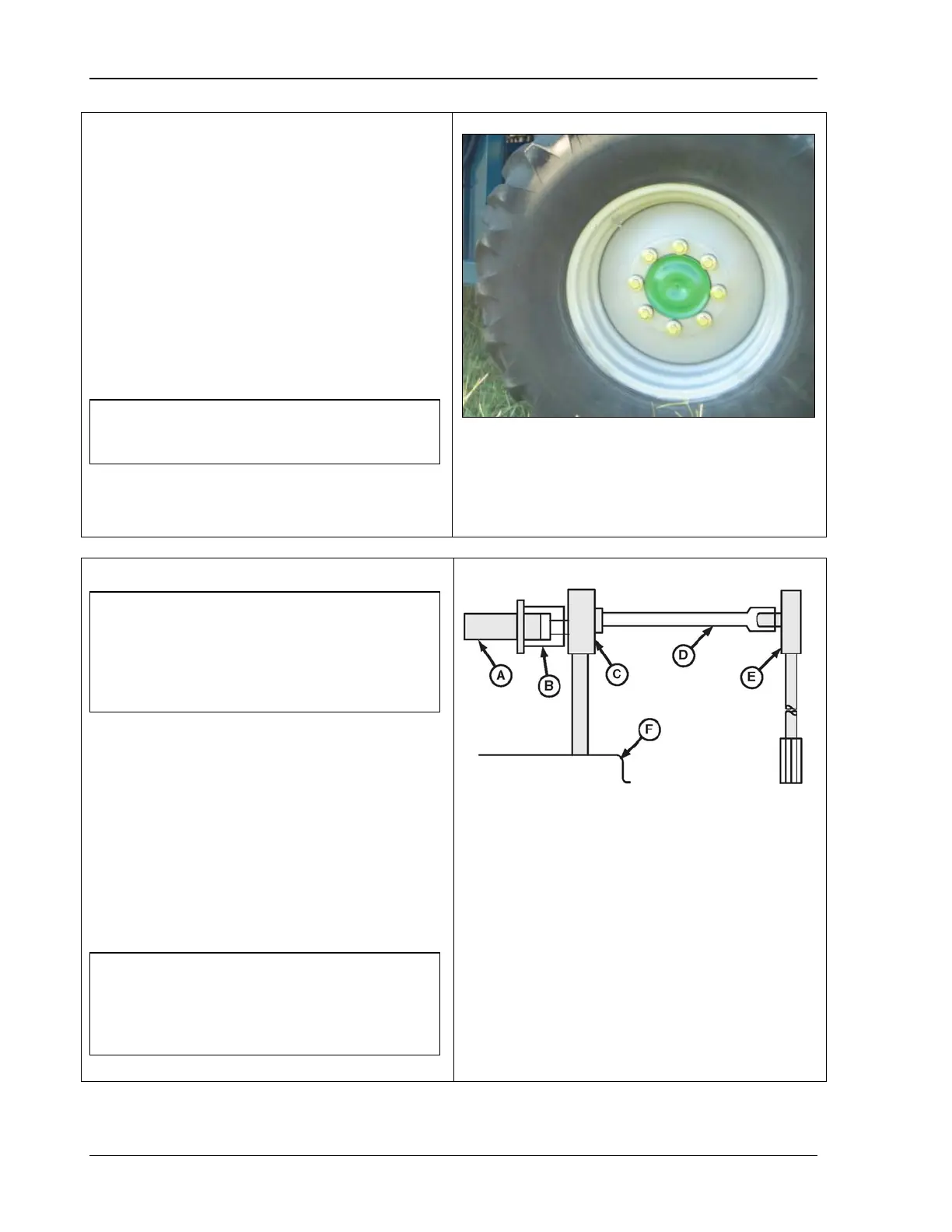

Drive Wheel Bolt Torque

1. Each time a drive wheel is repositioned or

replaced, torque the wheel bolts to 200

N*m (150 lb/ft) without using a torque

multiplier. Tighten the bolts in a criss-

cross pattern.

2. Once installed, u

multiplier and turn bolt head ¼ turn (ratchet

or torque wrench will make a full turn). Pull

the multiplier handle against inside of

wheel when you tighten bolts.

A – Wheel bolt

B – 30 mm socket

C – 4 to 1 multiplier

D – Extension

E – Torque wrench

F – Wheel

NOTE! Mount rear tires with the offset “in”

and valve stems in the outside.

IMPORTANT! Wheel bolts must be clean

and free of lube before they are installed.

Torque valve is for clean, dry bolts.

Lubricating reduces friction and overloads

the bolts.

NOTE! If the combine is equipped with

100mm (4 in.) wheel spacers, turn each

bolt head ½ turn (ratchet or torque wrench

will make two full turns).

280 09/04/15 MAN141

Loading...

Loading...