85-Maintenance Procedures

secondary and primary mass at the centering bore #2 and tap with a soft face

hammer onto the hub at the elongated centering hole. Refer to Fig. 85 - 43.

Make sure that the hub is correctly aligned at the flange of the secondary mass

before you tighten the screws.

Tighten the 8 screws on the hub.

Apply Loctite 243.

Refer to Fig. 85 - 44.

Make sure there is no clearance between the flange of the hub and the flange

of the secondary mass after you tighten the screws.

If you see a clearance and/or the centering pins are not in the correct position,

replace the hub and the two-mass-flywheel. Refer to Paragraph C and D.

Remove the flywheel locking tool.

Install the crankshaft sensors.

Refer to Section 76-10-00

Paragraph 4.B.

Connect the crankshaft sensors connector.

Install the starter on the engine.

Refer to Section 80-10-00

Paragraph 2.B.

Refer to Section 71-00-01.

Examine the gearbox oil system for leakage.

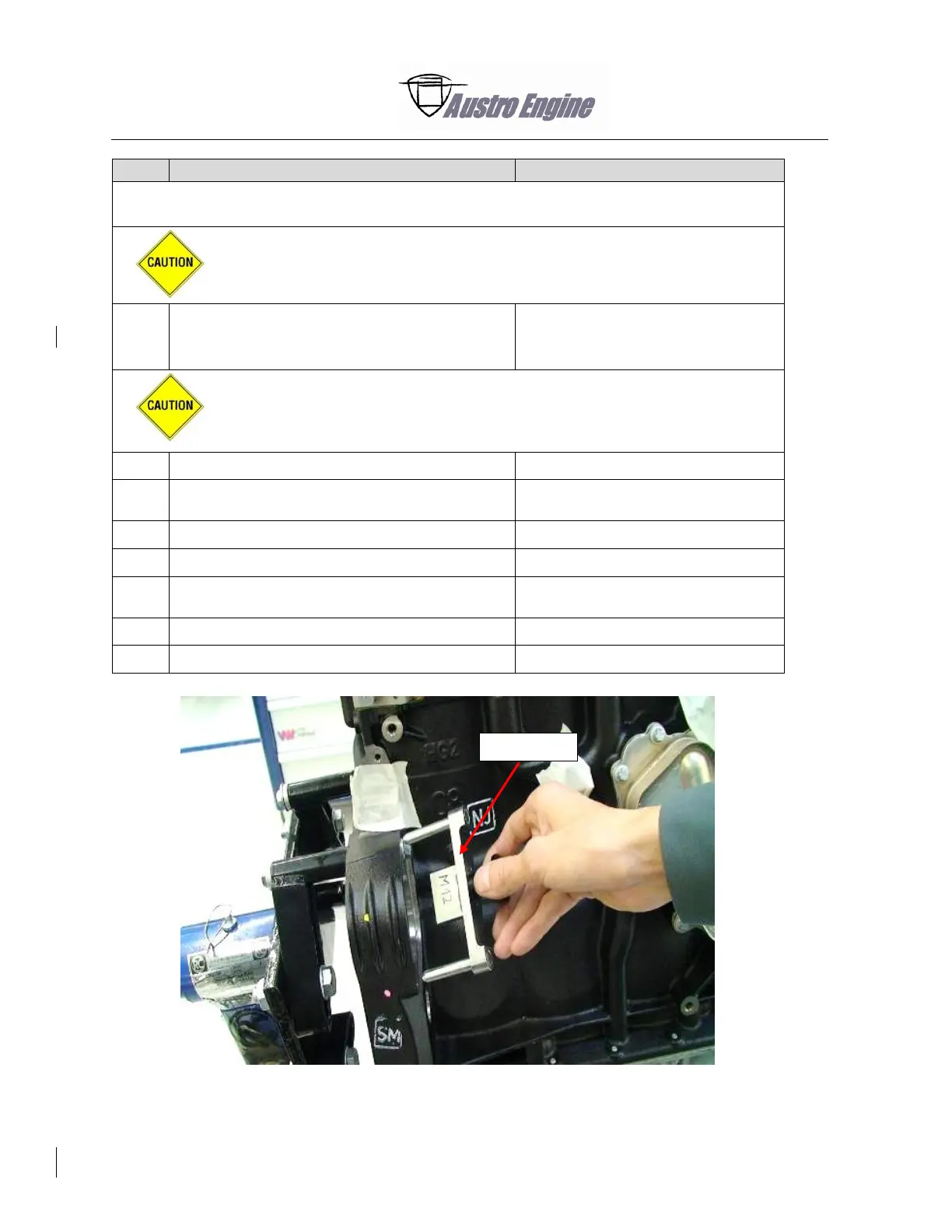

Fig. 85 - 38 Flywheel locking tool

Loading...

Loading...