IMPORTANT INFORMATION - 1B-190-824052R3 JUNE 2002

Specifications

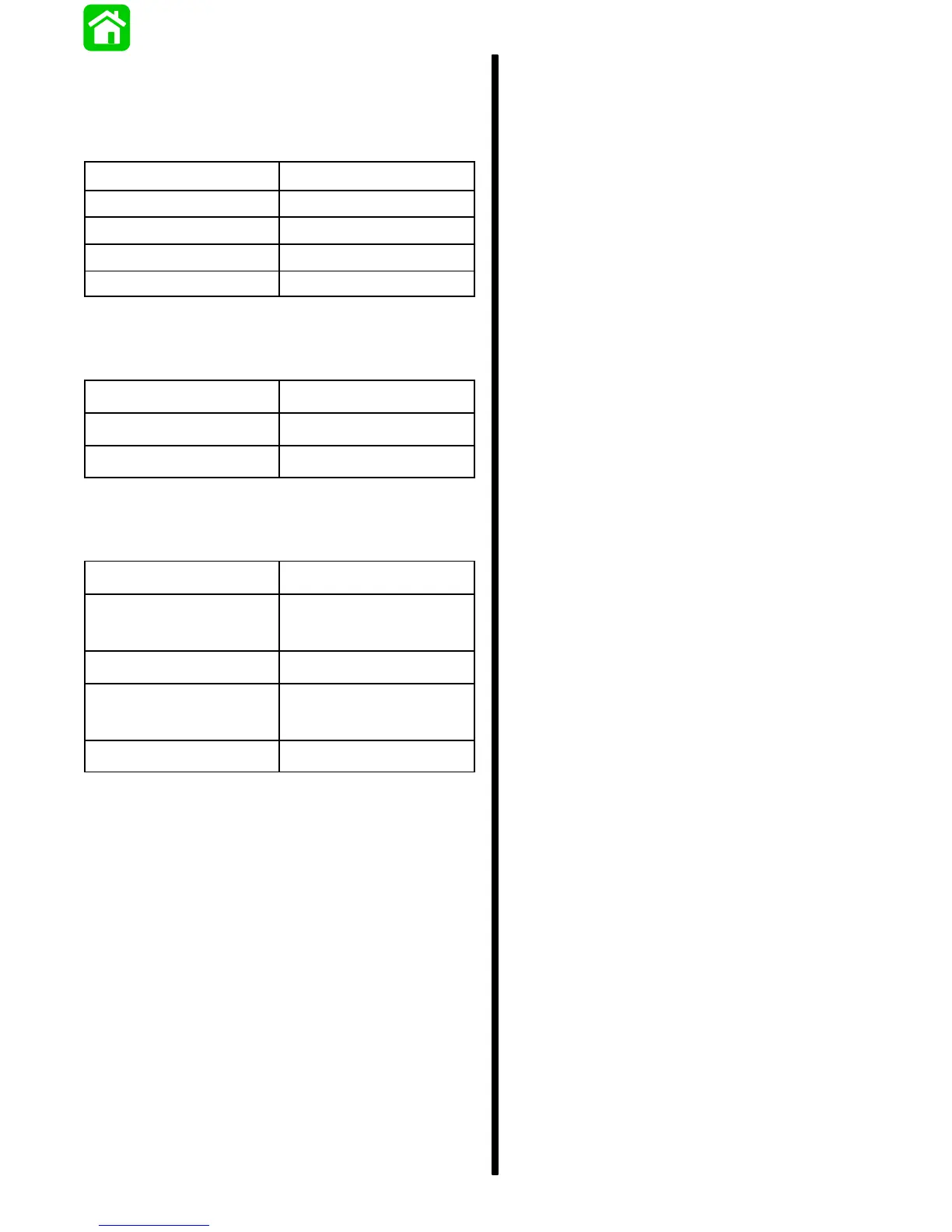

Gear Case Lubricant Capacity

Gear Case Ratio Capacity

1.78:1 21 fl. oz. (625ml)

1.87:1 24-1/4 fl oz. (717ml)

2.00:1 24-1/4 fl oz. (717ml)

2.30:1 24-1/4 fl oz. (717ml)

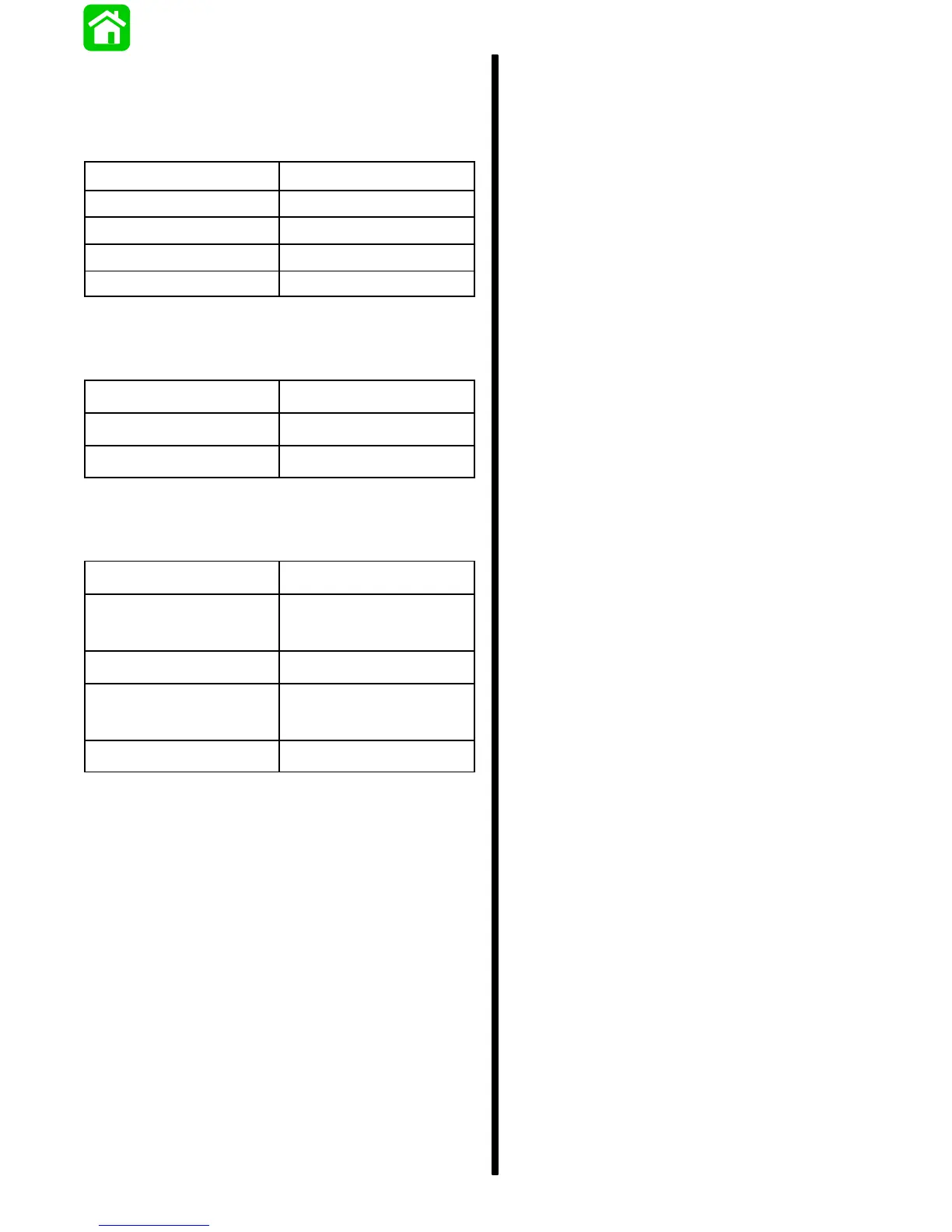

Special Tools

Description

Part No.

Flushing Attachment 44357A2

Grease Gun

91-37299A1

Quicksilver Lubricant/Sealant

Description Part No.

Gear Lubricant -

Premium Blend

92-19007A24

Anti-Corrosion Grease 92-78376A6

2-4-C Marine Lubricant

with Teflon

92-825407A12

SAE 30W Motor Oil Obtain Locally

Inspection and Maintenance

Schedule

Before Each Use

1. Check that lanyard stop switch stops the engine.

2. Visually inspect the fuel system for deterioration

or leaks.

3. Check outboard for tightness on transom.

4. Check steering system for binding or loose com-

ponents.

5. Visually check steering link rod fasteners for

proper tightness.

6. Check propeller blades for damage.

After Each Use

1. Flush out the outboard cooling system if operat-

ing in salt or polluted water.

2. Wash off all salt deposits and flush out the ex-

haust outlet of the propeller and gear case with

fresh water if operating in salt water.

Every 100 Hours of Use or Once

yearly, Whichever occurs first

1. Lubricate all lubrication points. Lubricate more

frequently when used in salt water.

2. Inspect and clean spark plugs.

3. Check engine fuel filter for contaminants – Car-

buretor models.

4. Replace Water separating fuel filter – EFI mod-

els.

5. Check corrosion control anodes. Check more fre-

quently when used in salt water.

6. Drain and replace gear case lubricant.

7. Lubricate splines on the drive shaft.

∗

8. Check power trim fluid.

9. Inspect battery.

10. Adjust carburetors (if required).

∗

11. Check engine timing setup.∗

12. Check control cable adjustments.∗

13. Remove engine deposits with Quicksilver Power

Tune Engine Cleaner.

Loading...

Loading...