90-824052R3 JUNE 2002 FUEL SYSTEMS - 3D-35

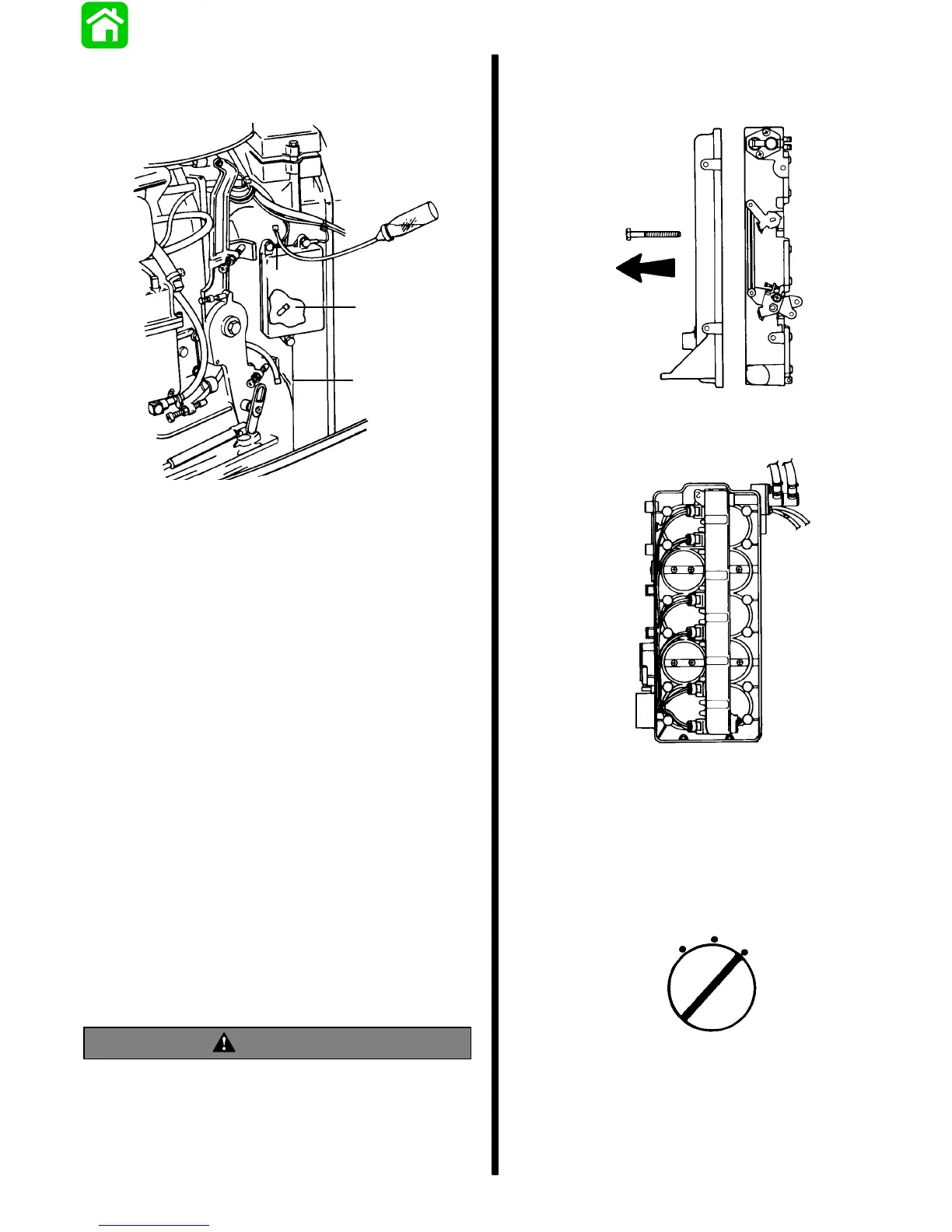

NOTE: Switch box panel and lube alert control box

may have to be shifted to the side to allow bleed fitting

connection. Ground boxes to engine as required.

a

a

a

50342

a - Bleed Line Fittings (Inject fuel at this location)

Results: If RPM increase occurs while injecting fuel

into disabled cylinder, clogged injector filter or

defective injector may be the problem. Per-

form Induction Manifold Disassembly (page

3D-55) for inspection.

NOTE: Injector fuel delivery can be tested with

manifold cover removed. See Injector Operation Test

(manifold cover removed) below.

RPM does not change when injecting fuel into bleed

fittings could indicate lack of compression, damaged

reeds, end cap seals, crankcase split line seal, or

crankshaft sealing rings.

Remaining tests on EFI components may require

some EFI disassembly. See EFI System

Disassembly following.

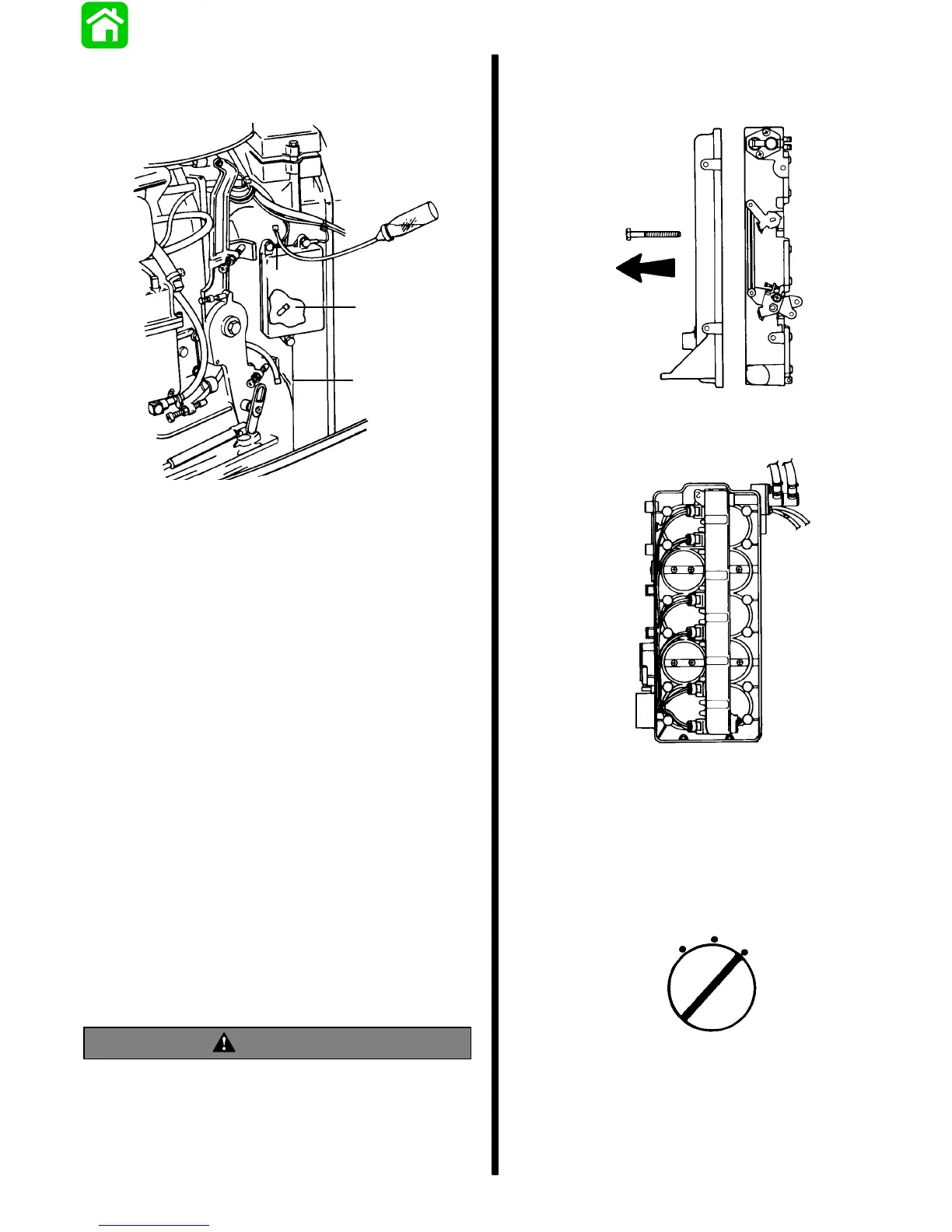

Injector Operation Test (Manifold

Cover Removed)

Purpose: This test determines if the injectors are

actually injecting fuel into the engine at a

normal rate.

WARNING

Do not start engine with induction manifold

cover removed. Disable ignition system prior to

doing this test.

1. Remove induction manifold cover using

procedures outlined under “lnduction Manifold

Removal.”

2. Re-attach induction manifold to engine using

1/4-20 x 2-3/4″ screws.

3. Connect a jumper wire between the ECM metal

case and a good engine ground.

4. Disconnect all spark plug wires from spark plugs

and seal leads with electrical tape to prevent

sparking.

5. Put ignition key switch in “START” position.

OFF

ON

START

6. Look at injector spray pattern using an explosive

proof flashlight.

Loading...

Loading...