90-824052R3 JUNE 2002 LOWER UNIT - 6A-39

Reassembly and Installation

Standard Rotation

Driveshaft Needle Bearing

REASSEMBLY/INSTALLATION

CAUTION

If driveshaft needle bearing failure has occurred,

and original bearing race has turned in the gear

housing, gear housing MUST be replaced. Loose

fitting needle bearing will move out of position

and cause repeated failures.

1. Apply a thin coat of Quicksilver Needle Bearing

Assembly Lubricant to driveshaft needle bearing

bore in gear housing.

2. By way of propeller shaft cavity, place needle

bearing in drive shaft bore with numbered side of

bearing facing up drive shaft bore.

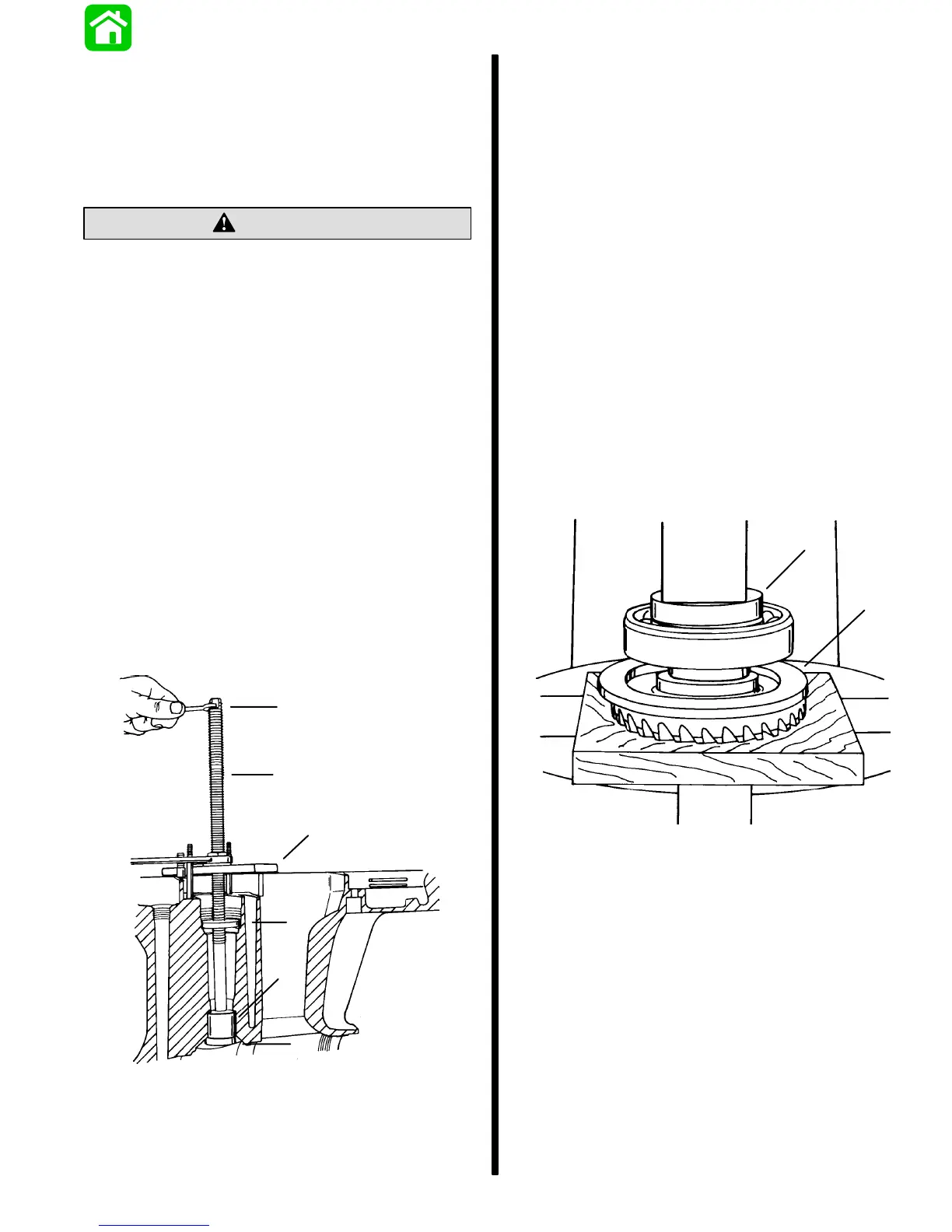

3. Install and seat needle bearing with the following

tools: Puller Rod* (91-31229), Nut* (11-24156),

Pilot* (91-36571), Plate* (91-29310), and

Mandrel (models with preloaded driveshaft use

91-38628*; models with standard driveshaft use

91-92788). Pull bearing up into bore until it

bottoms on gear housing shoulder. (DO NOT use

excessive force.)

*

From Bearing Removal and Installation Kit (91-31229A5)

f

e

d

c

b

a

51869

a - Mandrel

b - Bearing

c - Pilot

d - Plate

e - Puller Rod

f - Hold

Bearing Carrier

REASSEMBLY

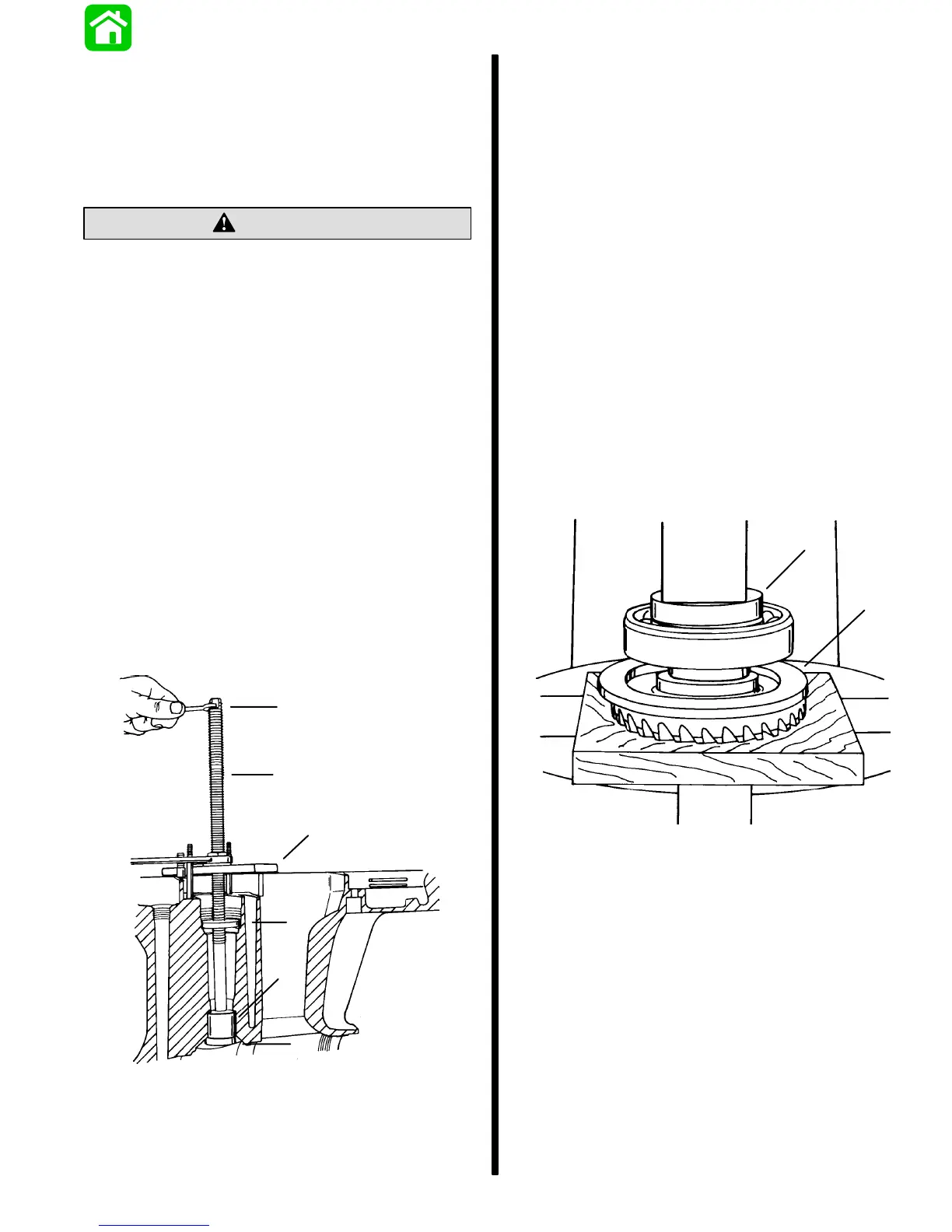

1. Place reverse gear on a press with gear teeth

facing down.

IMPORTANT: The reverse gear thrust washer has

a tapered outside diameter so that one side is

larger than the other. The larger outside diameter

of washer must be toward reverse gear.

2. Place thrust washer over gear with the larger

outside diameter down toward gear.

3. Apply a light coat of Quicksilver Super Duty Gear

Lubricant onto inside diameter of reverse gear

ball bearing.

4. Position ball bearing over gear (with numbered

side of bearing up).

5. Press ball bearing onto gear with a suitable

mandrel until firmly seated. (Be sure to press only

on inner race of bearing and that bearing is firm

against gear.)

b

a

51873

a - Thrust Washer

b - Mandrel

6. Apply a light coat of Quicksilver Super Duty Gear

Lubricant onto outside diameter of propeller shaft

needle bearing.

7. Place propeller shaft needle bearing into aft end

of bearing carrier with numbered side toward aft

end.

NOTE: On high performance CLE, Sport Master and

Torque Master gearcases, a retaining ring is installed

after propeller shaft needle bearing is installed in

bearing carrier.

Loading...

Loading...