90-824052R3 JUNE 2002 POWERHEAD - 4A-29

Crankshaft

1. Inspect crankshaft to drive shaft splines for wear.

(Replace crankshaft, if necessary.)

2. Check crankshaft for straightness. (Replace as

necessary.)

3. Inspect crankshaft oil seal surfaces. Sealing sur-

faces must not be grooved, pitted or scratched.

(Replace as necessary.)

4. Check all crankshaft bearing surfaces for rust,

water marks, chatter marks, uneven wear and/or

overheating. (Refer to “Connecting Rods”.)

5. If necessary, clean crankshaft surfaces with

crocus cloth.

b

a

c

c

51847

a - Crankshaft Journals

b - Crocus Cloth

c - Work Cloth “Back-and-Forth”

WARNING

DO NOT spin-dry crankshaft ball bearing with

compressed air.

6. Thoroughly clean (with solvent) and dry

crankshaft and crankshaft ball bearing. Recheck

surfaces of crankshaft. Replace crankshaft, if

surfaces cannot be properly “cleaned up.” If

crankshaft will be re-used, lubricate surfaces of

crankshaft with light oil to prevent rust. DO NOT

lubricate crankshaft ball bearing at this time.

Crankshaft (and End Cap) Bearings

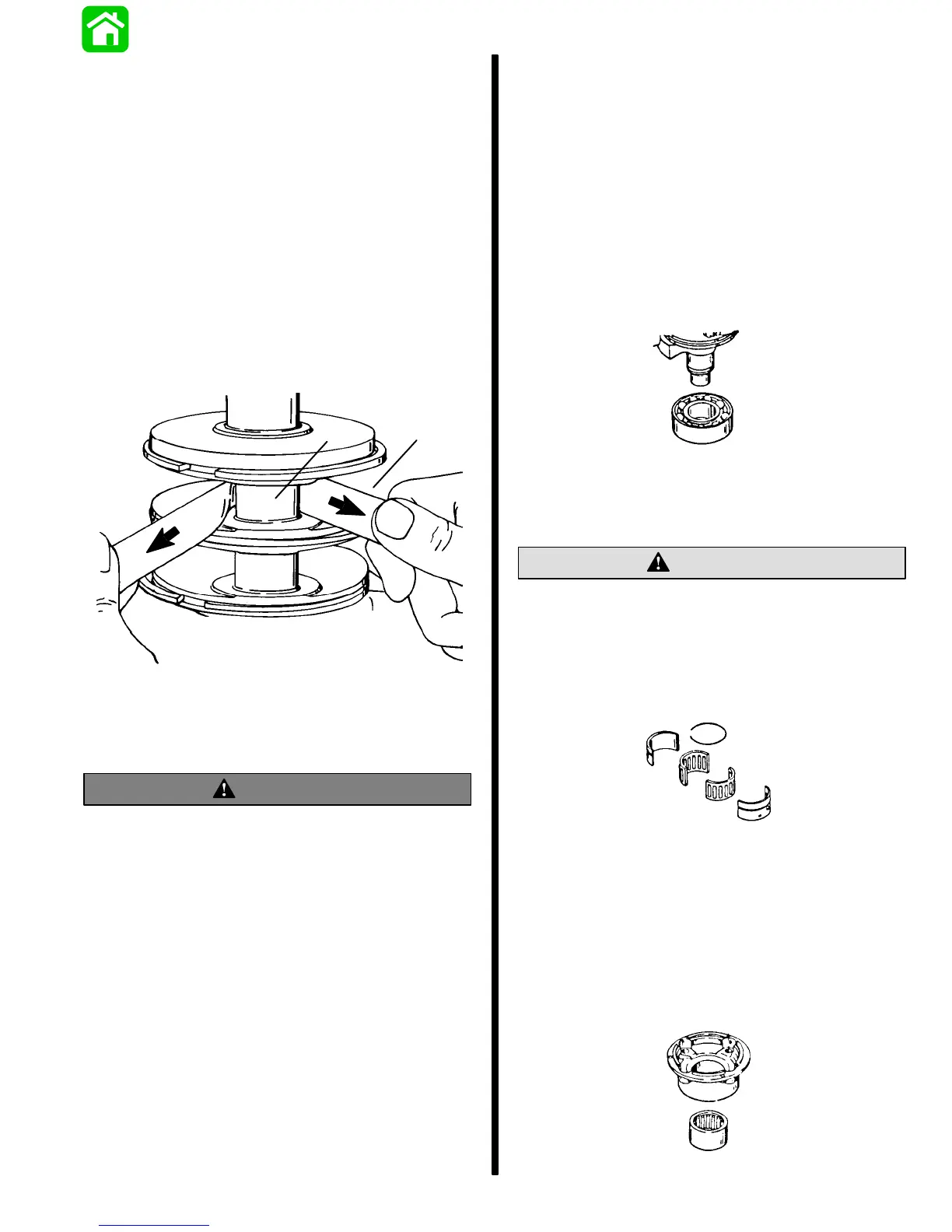

1. After cleaning crankshaft, grasp outer race of

crankshaft ball bearing (installed on lower end of

crankshaft) and attempt to work race back-and-

forth. There should not be excessive play.

2. Lubricate ball bearing with light oil. Rotate outer

bearing race. Bearing should have smooth action

and no rust stains. If ball bearing sounds or feels

“rough” or has “catches,” remove and discard

bearing. (Refer to “Powerhead Removal and

Disassembly - Crankshaft Removal and

Disassembly”).

Lower Ball

Bearing

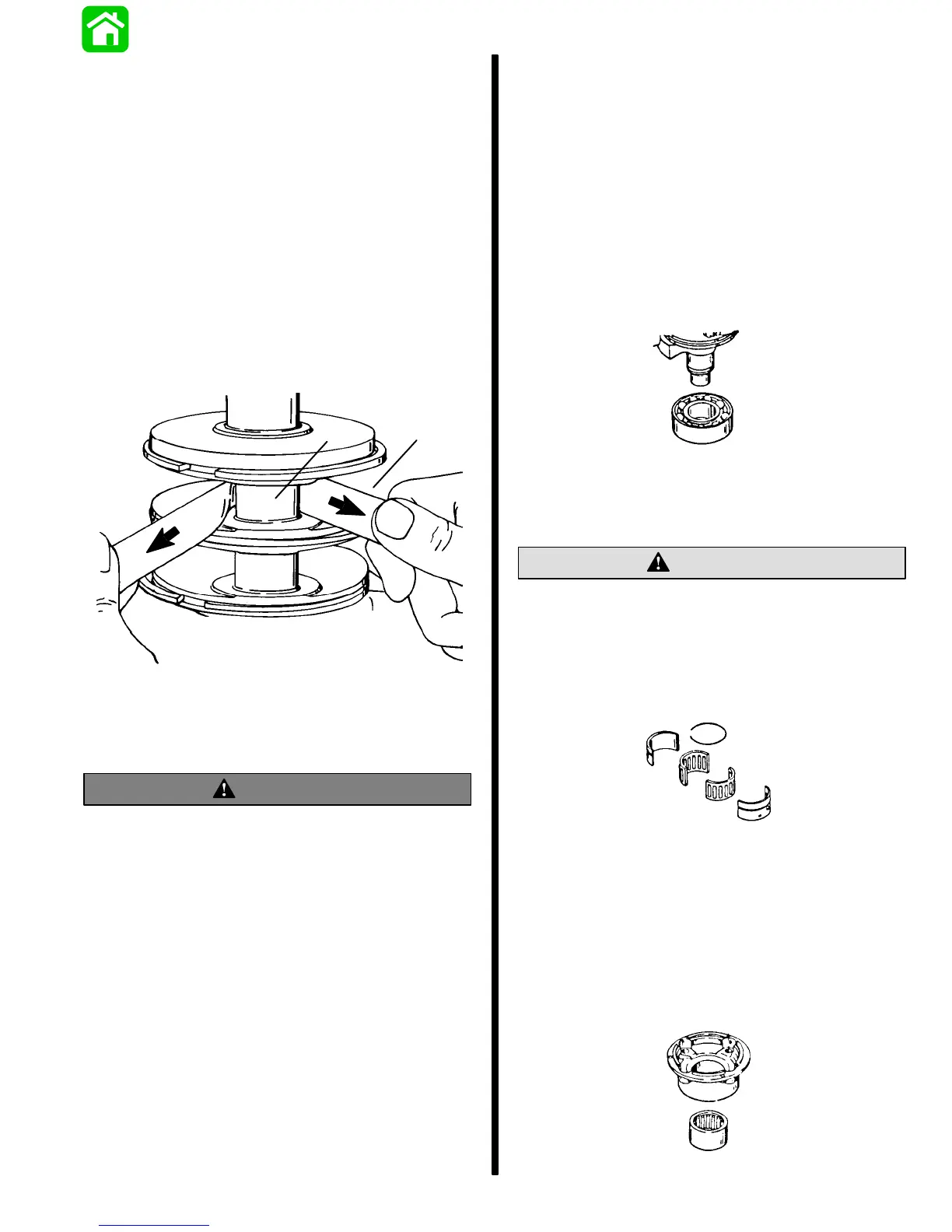

3. Thoroughly clean (with solvent) and dry

crank-shaft center main roller bearings.

Lubricate bearings with 2-Cycle Outboard Oil.

CAUTION

DO NOT intermix halves of upper and lower

crank- shaft center main roller bearings. Replace

bearings in pairs only.

4. Thoroughly inspect center main roller bearings.

Replace bearings if they are rusted, fractured,

worn, galled or badly discolored.

Center main

Roller Bearing

5. Clean (with solvent) and dry crankshaft roller

bearing that is installed in upper end cap. Lubri-

cate bearing with light oil.

6. Thoroughly inspect upper end cap roller bearing.

If roller bearing is rusted, fractured, worn, galled,

badly discolored or loose inside of end cap

replace end cap and roller bearing as an

assembly.

Upper Roller

Bearing

Loading...

Loading...