90-824052R3 JUNE 2002 FUEL SYSTEMS - 3D-51

Vapor Separator Reassembly

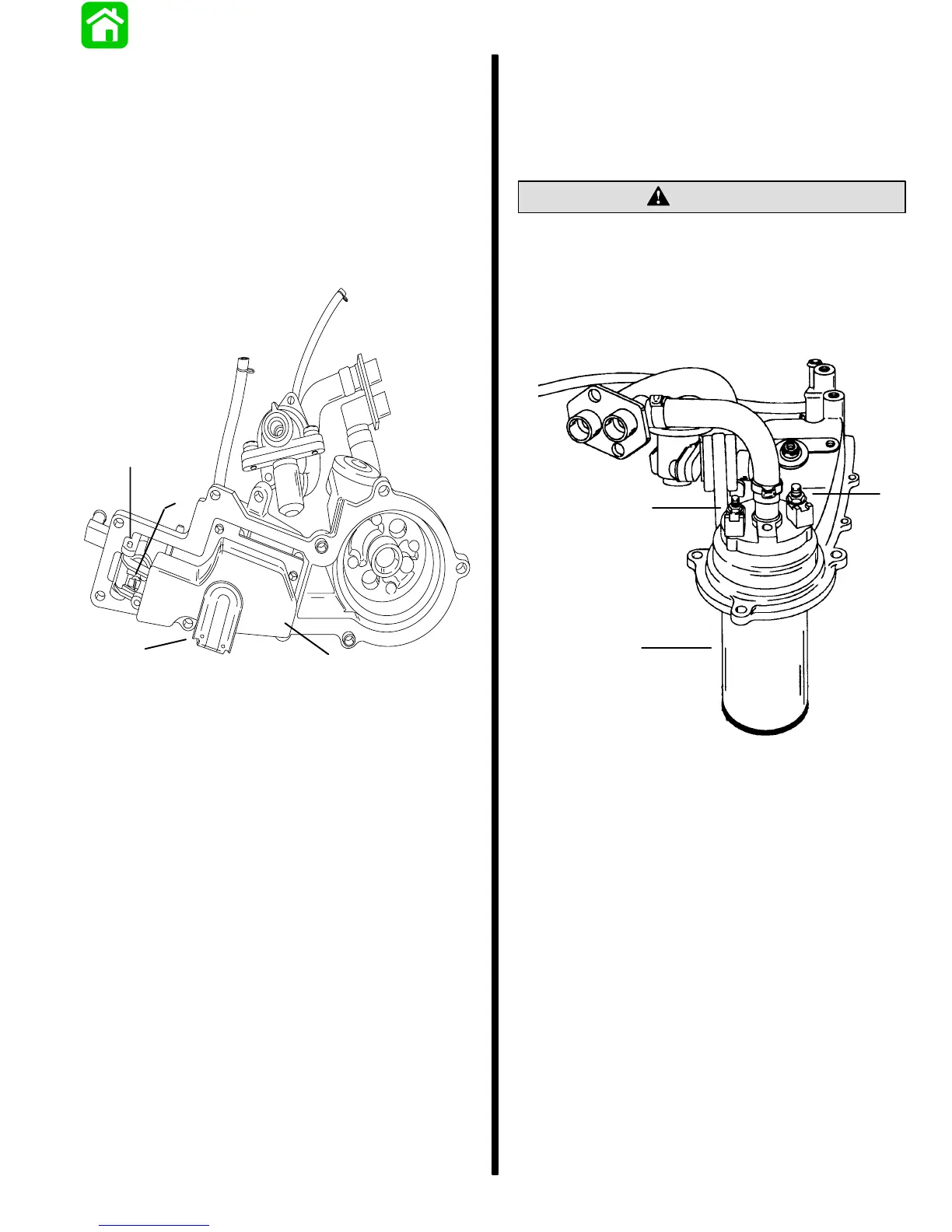

VAPOR SEPARATOR FLOAT INSTALLATION

1. Attach float needle to float arm.

2. Guide float/needle assembly under float drop

limit bracket and place needle into seat.

3. Slide pivot pin through float arms.

4. Verify float’s freedom of movement through pivot

range.

55207

a

c

d

b

a - Float

b - Float Needle (Hidden)

c - Float Drop Limit Bracket

d - Pivot Pin

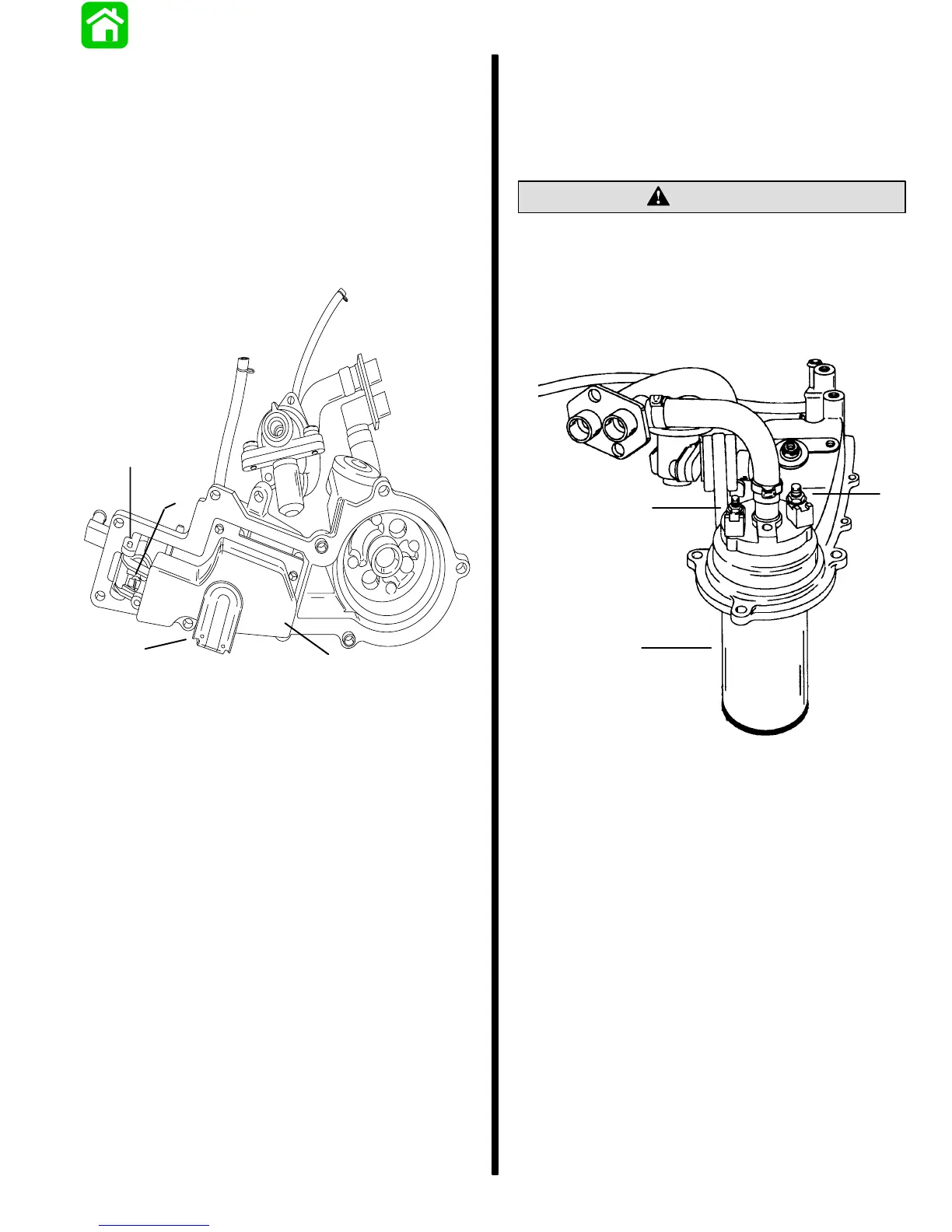

ELECTRIC FUEL PUMP INSTALLATION

1. Slide fuel pump into separator cover.

NOTE: Fuel pump electrical studs are different

diameters. Pump will install properly into cover only

one way.

CAUTION

DO NOT over torque fuel pump POSITIVE and

NEGATIVE attaching nuts as damage to fuel

pump will result.

2. Secure pump to cover with 2 nuts. Torque POS-

ITIVE nut to 6 lb. in. (0.7 N·m). Torque NEGATIVE

nut to 8 lb. in. (0.9 N·m).

c

b

a

a - Electric Pump

b - POSITIVE (+) Stud (Small Diameter)

c - NEGATIVE (–) Stud (Large Diameter)

Loading...

Loading...