6C-14 - LOWER UNIT 90-824052R3 JUNE 2002

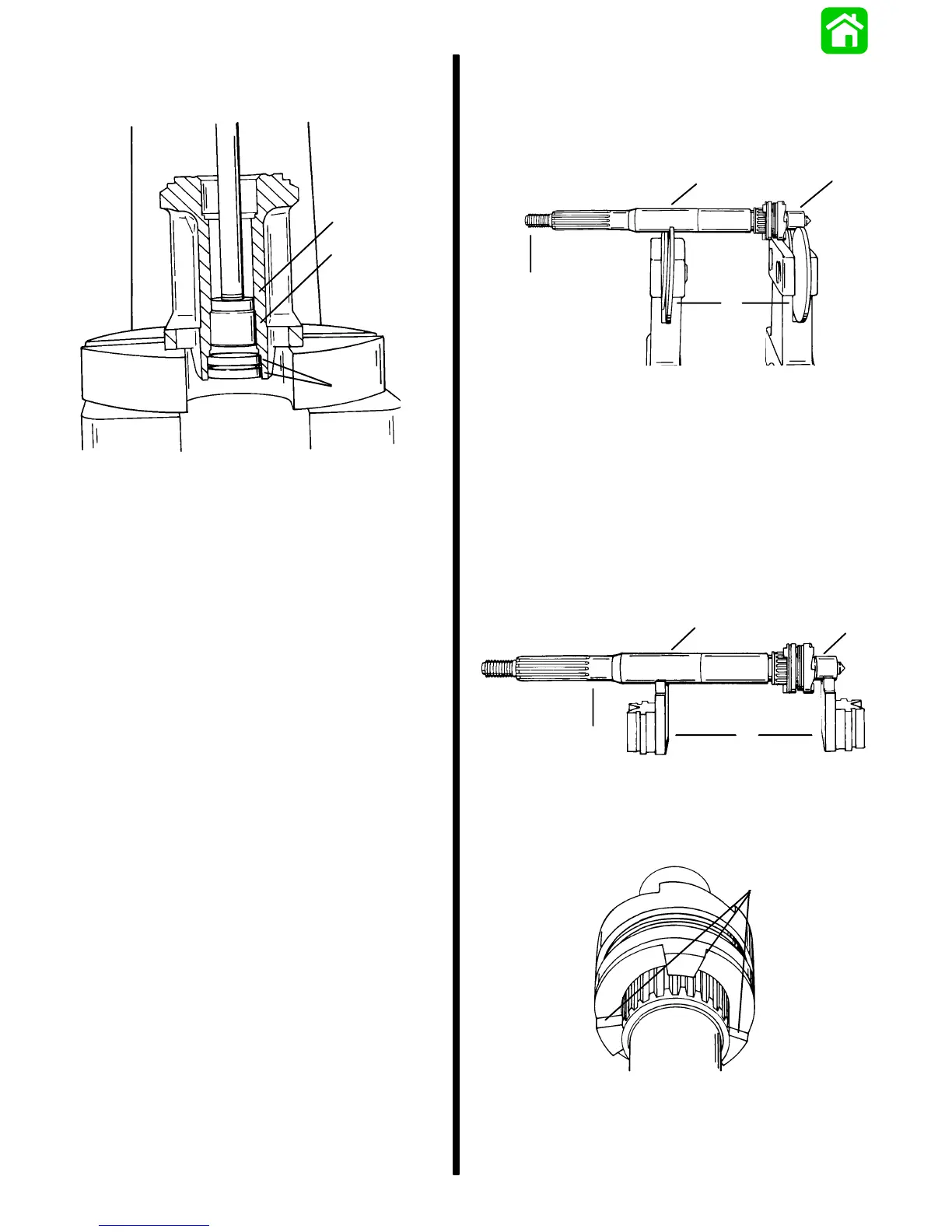

NOTE: Reverse gear must be removed from bearing

carrier before propeller shaft needle bearing can be

removed.

b

c

51884

a

a - Propeller Shaft Needle Bearing

b - Mandrel

c - Oil Seals

PROPELLER SHAFT CLEANING AND

INSPECTION

NOTE: Cam follower and 3 metal balls (in end of

propeller shaft) are free and will fall out. Care should

be taken not to lose cam follower or 3 balls.

1. Clean propeller shaft assembly with solvent and

dry with compressed air.

2. Inspect bearing carrier oil seal surfaces for

grooves. Run fingernail across seal surface to

check for grooves. Replace shaft, if a groove is

found.

3. Visually check bearing surfaces of propeller shaft

for pitting, grooves, scoring, uneven wear or

discoloration (bluish color) from overheating.

Replace shaft and corresponding needle bearing

if any of the above conditions are found. (Bearing

carrier needle bearing contacts propeller shaft

just in front of oil seal surface. Forward gear

bearing contacts propeller shaft in front of sliding

clutch splines).

4. Inspect propeller shaft splines for wear and/or

corrosion damage.

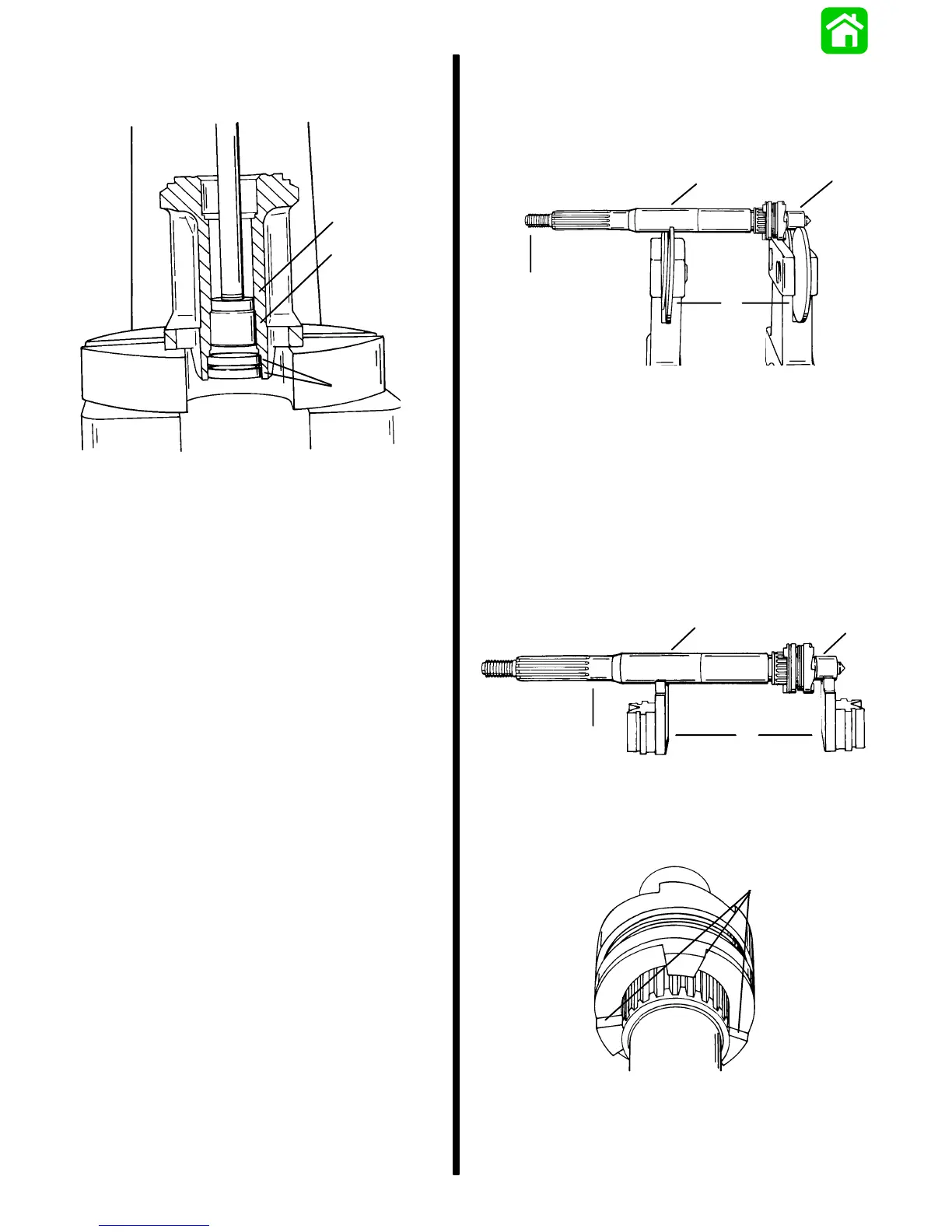

5. Check propeller shaft for straightness. Use either

method, following:

Balance Wheels

Place propeller shaft on balance wheels. Rotate

propeller shaft, observe propeller end of shaft for

“wobble” and replace shaft if any “wobble” is

observed.

c

b

a

b

51877

a - Balance Wheels

b - Bearing Surfaces

c - Watch for “Wobble”

“Vee” Blocks and Dial Indicator

Position propeller shaft needle bearing surfaces on

“Vee” blocks. Mount a dial indicator at front edge of

propeller splines. Rotate propeller shaft. Dial

indicator movement of more than 0.006″ (0.152mm)

(or noticeable “wobble”) is reason for replacement.

b

c

a

b

51877

a - “Vee” Blocks

b - Bearing Surfaces

c - Measure with Dial Indicator at This Point

a

51876

a - Clutch “Dogs”

Loading...

Loading...