3C-34 - FUEL SYSTEMS 90-824052R3 JUNE 2002

STEP 3: Connect a jumper wire between the

metal case of ECM and a good engine

ground.

WARNING

If a serious leak is present in the induction man-

ifold, fuel may spray out of bad seal. Have clean

up rags available to remove excess fuel from

components.

STEP 4: Place emergency stop switch in OFF

position to prevent engine from starting. If

boat is not equipped with a emergency

stop switch, connect a jumper lead from

the BLACK/YELLOW terminal on the

switch box to engine ground.

STEP 5: Connect remote starter Quicksilver

(91-52024A1) to negative terminal of

electric fuel pump and a good engine

ground. Depress remote start switch,

pump will operate as long as switch is

depressed.

WARNING

Do not operate pump for more than 20 seconds

continuously.

STEP 6: Look for leak points on induction man-

ifold while depressing remote starter

switch.

Results: If no leaks are present, replace cover and

gasket using normal length screws.

If fuel leak is present between sealing surfaces,

rebuild system using new O-rings.

Air Temperature Sensor Test

Purpose: This test eliminates possibilities of im-

proper fuel delivery related to air temperature

sensor.

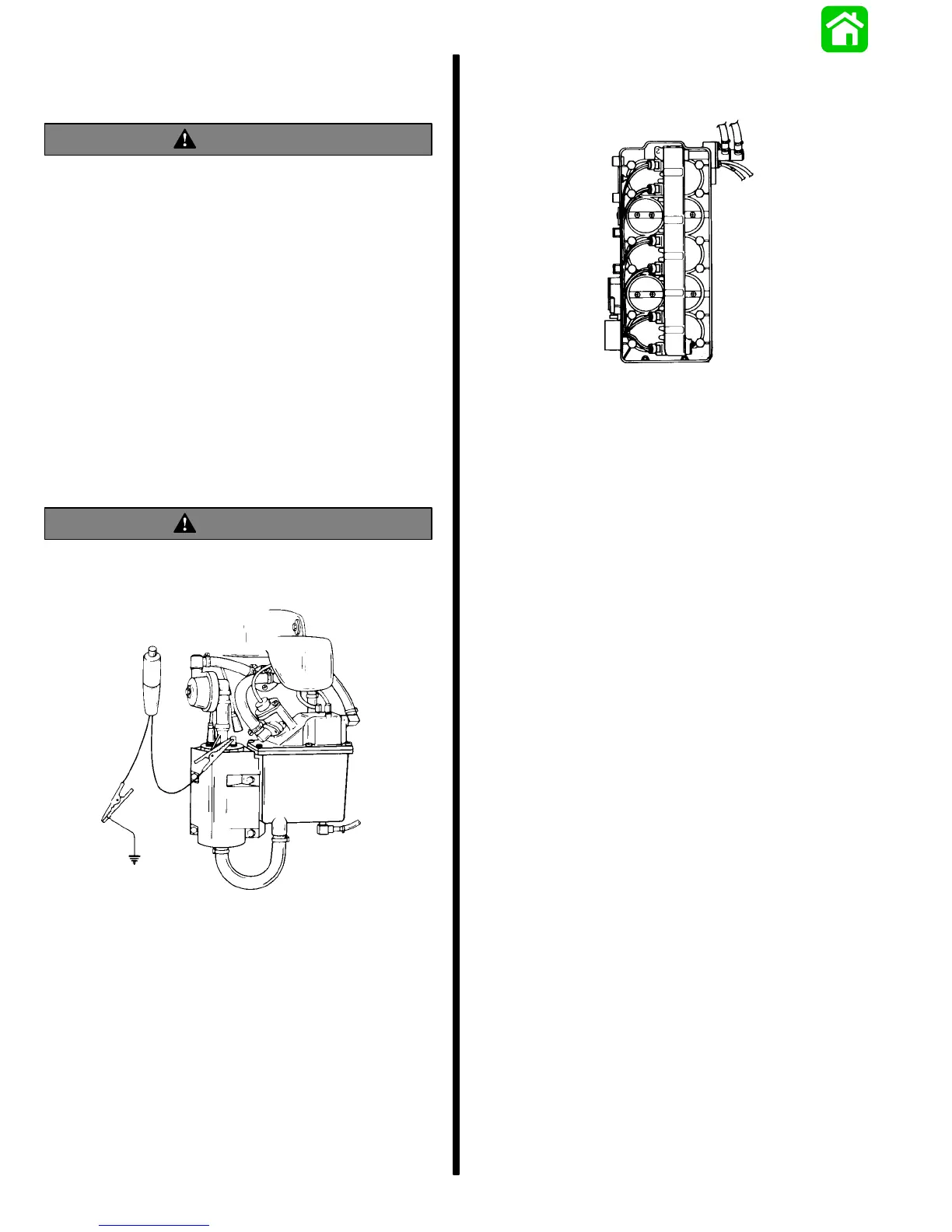

Procedure: STEP 1: Disconnect and remove Air

Temperature Sensor from induction man-

ifold.

STEP 2: Connect digital meter set at “20K scale”

(from EFI Tester P/N 91-11001A2) to

leads of sensor.

STEP 3: Place sensor in ice water while monitor-

ing meter reading. Use graph (following

page) for reference.

Loading...

Loading...