IMPORTANT INFORMATION - 1B-790-824052R3 JUNE 2002

4. Place rear thrust hub on propeller shaft.

5. Place locking tab washer on propeller shaft, then

thread propeller nut on shaft.

6. Place propeller nut into recess in locking tab

washer and torque propeller nut to 55 lb. ft. (74.5

N·m). Verify nut is recessed into tab washer while

applying torque.

7. Bend 3 tabs from locking tab washer down into

grooves of propeller hub to secure propeller nut.

8. After first use, bend three tabs straight and retor-

que propeller nut [55 lb. ft. (74.5 N·m)]. Bend tabs

down into propeller hub grooves (check periodi-

cally for tightness.)

CAUTION

If propeller moves fore-and-aft on the propeller

shaft, retighten the propeller nut. Operation with

a loose propeller could cause damage to the

thrust hub and gear housing during acceleration,

deceleration or when shifting gears.

c

d

e

c - Locking Tab Washer (Bend Tabs into Thrust Hub Grooves)

d - Propeller Nut

e - Rear Thrust Hub

Corrosion Control Anode

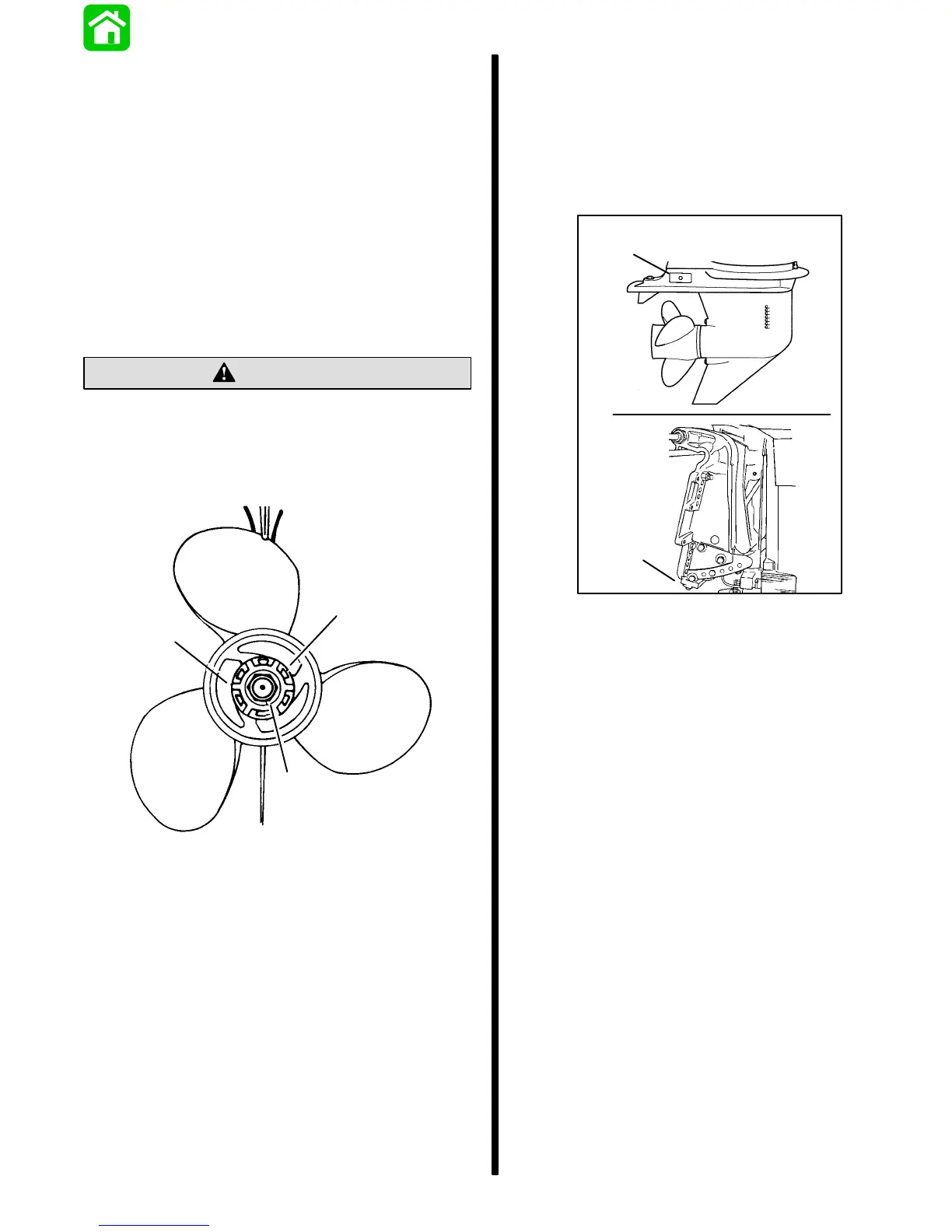

The gear case has two corrosion control anodes.

Another anode is installed on the bottom of the tran-

som bracket assembly. An anode helps protect the

outboard against galvanic corrosion by sacrificing its

metal to be slowly eroded instead of the outboard

metals.

a

b

a - Gear Case Anodes (2)

b - Transom Bracket Anode

Each anode requires periodic inspection especially

in salt water which will accelerate the erosion. To

maintain this corrosion protection, always replace

the anode before it is completely eroded. Never paint

or apply a protective coating on the anode as this will

reduce effectiveness of the anode.

Loading...

Loading...