90-824052R3 JUNE 2002 LOWER UNIT - 6D-27

Driveshaft and Pinion Gear

REASSEMBLY/INSTALLATION

1. Apply a light coat of Quicksilver Super Duty Gear

Lubricant on l.D. of driveshaft tapered bearing.

2. Thread a used pinion nut onto end of driveshaft.

Leave approximately 1/16″ (2mm) of nut threads

exposed. Driveshaft threads MUST NOT extend

beyond nut or thread damage could result while

pressing.

3. Place bearing over driveshaft.

4. Using an old driveshaft bearing inner race or

other suitable mandrel (which applies pressing

force on center bearing race only), press bearing

onto shaft until seated.

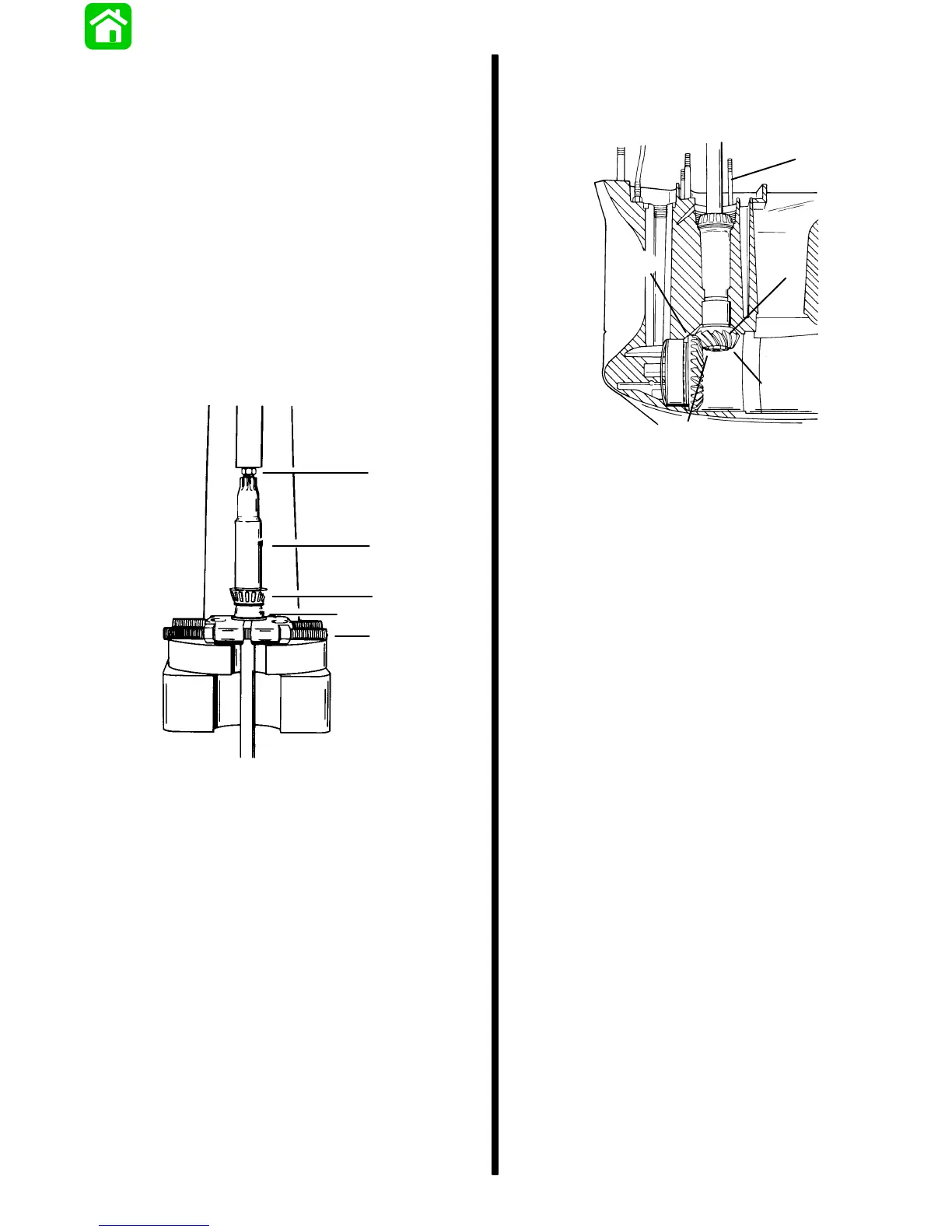

a

b

c

d

e

a - Used Pinion Nut

b - Driveshaft

c - Tapered Bearing

d - Old Bearing Inner Race

e - Universal Puller Plate

5. Position pinion gear in gear housing below drive-

shaft bore with teeth of pinion gear meshed with

teeth of forward gear.

6. Insert driveshaft into driveshaft bore while

holding pinion gear. Rotate driveshaft to align

and engage driveshaft splines with pinion gear

splines. Continue to insert driveshaft into gear

housing until driveshaft tapered bearing is

against bearing race.

NOTE: It is recommended that after final pinion depth

is obtained, a new pinion nut be installed. Clean

pinion nut threads with Loctite Primer N (92-59327-1)

before applying Loctite 271.

7. Place a small amount of Loctite 271 onto threads

of pinion gear nut and install flat washer and nut

on driveshaft with flat side of nut away from pinion

gear. Hand tighten pinion nut.

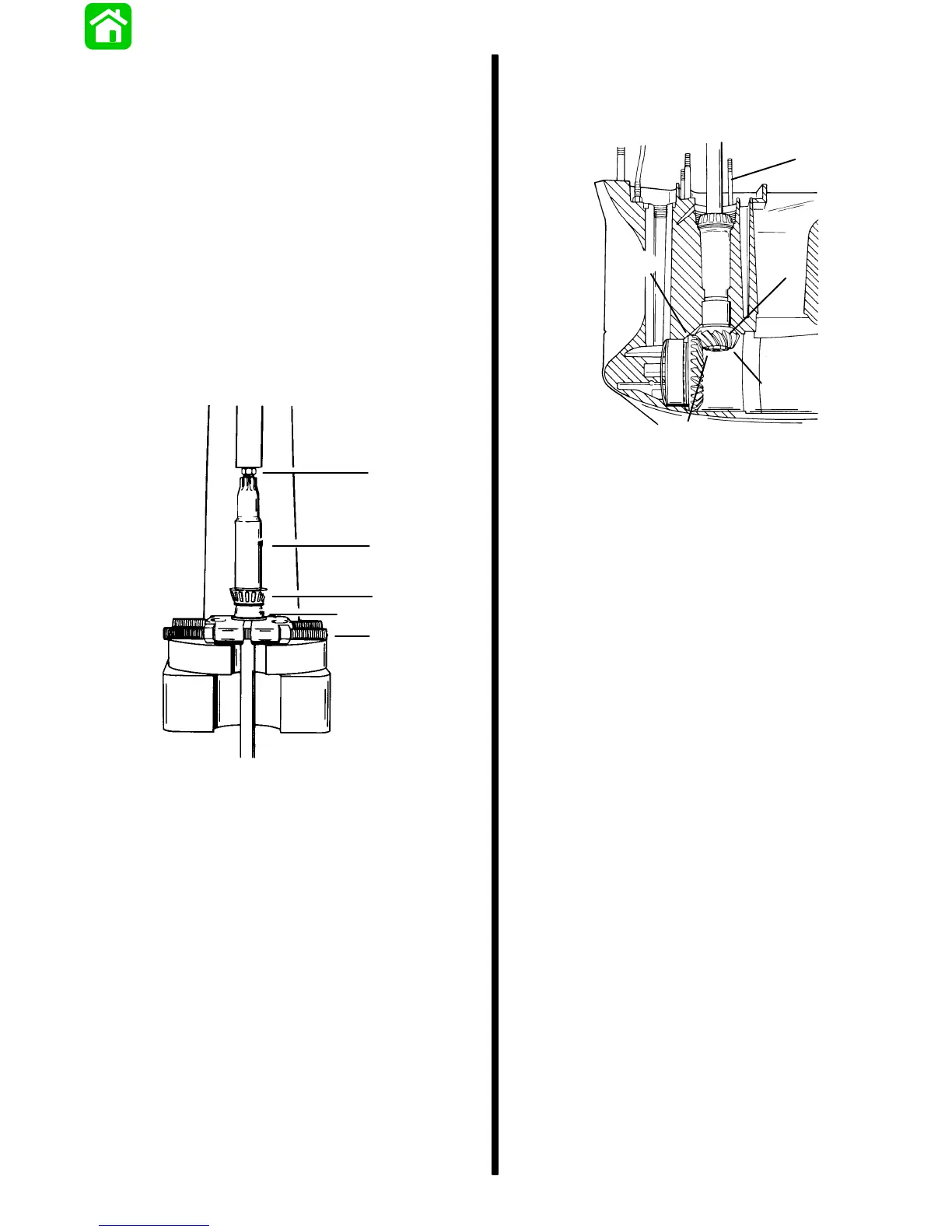

a

c

d

e

b

51867

a - Driveshaft (rotate to engage splines with pinion gear)

b - Forward Gear Assembly

c - Pinion Gear

d - Washer (located above pinion nut)

e - Pinion Nut (apply Loctite 271 on threads and install with

flat side away from pinion gear.)

Loading...

Loading...