1D-12 - IMPORTANT INFORMATION 90-824052R3 JUNE 2002

Bleeding Air from Oil Injection Pump

and Oil Injection Outlet Hose

BLEEDING AIR FROM OIL INJECTION PUMP

With engine not running, place a shop towel below

the oil injection pump. Loosen bleed screw three to

four turns and allow oil to flow from bleed hole. Re-

tighten bleed screw. This procedure allows the pump

to fill with oil.

BLEEDING AIR FROM OIL INJECTION PUMP

OUTLET HOSE

Any air bubbles in outlet hose in most cases will be

purged out of the system during operation of the

engine.

NOTE: If air bubbles persist, they can be purged out

of the hose by removing link rod and rotating the

pump arm full clockwise while operating engine at

1000 to 1500 RPM: If necessary, gently pinch the fuel

line between the remote fuel line connector and the

oil injection pump “Tee” fitting. This will cause the fuel

pump to provide a partial vacuum which will aid in re-

moval of the air. Reinstall link rod.

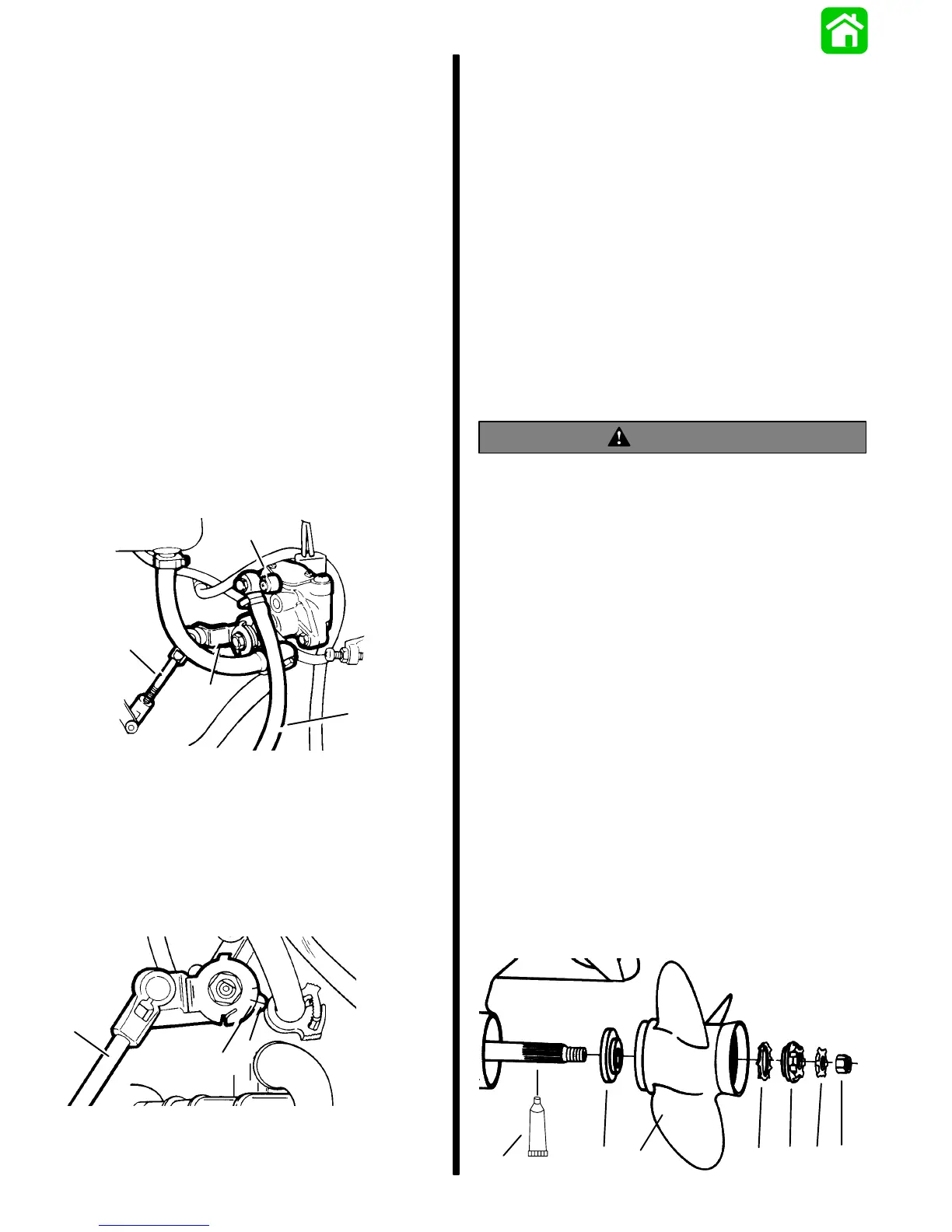

a

b

d

c

50047

a - Bleed Screw

b - Outlet Hose

c - Link Rod

d - Pump Arm

Adjusting Oil Injection Pump

When throttle linkage is at idle position, alignment

mark on oil injection arm should be in-line with mark

on casting as shown. If necessary, adjust link rod.

50060

a

b

c

a - Link Rod

b - Alignment Mark

c - Casting Mark

Propeller Selection

Refer to “Quicksilver Accessory Guide” for a com-

plete list of available propellers.

For best all around performance from your outboard/

boat combination, select a propeller that allows the

engine to operate in the upper half of the recom-

mended full throttle RPM range with the boat

normally loaded (refer to Specifications in the

Operators Manual). This RPM range allows for

better acceleration while maintaining maximum boat

speed.

Check full-throttle RPM using an accurate tachome-

ter with the engine trimmed out to a balanced steer-

ing condition (steering effort equal in both directions)

without causing the propeller to “break loose.”

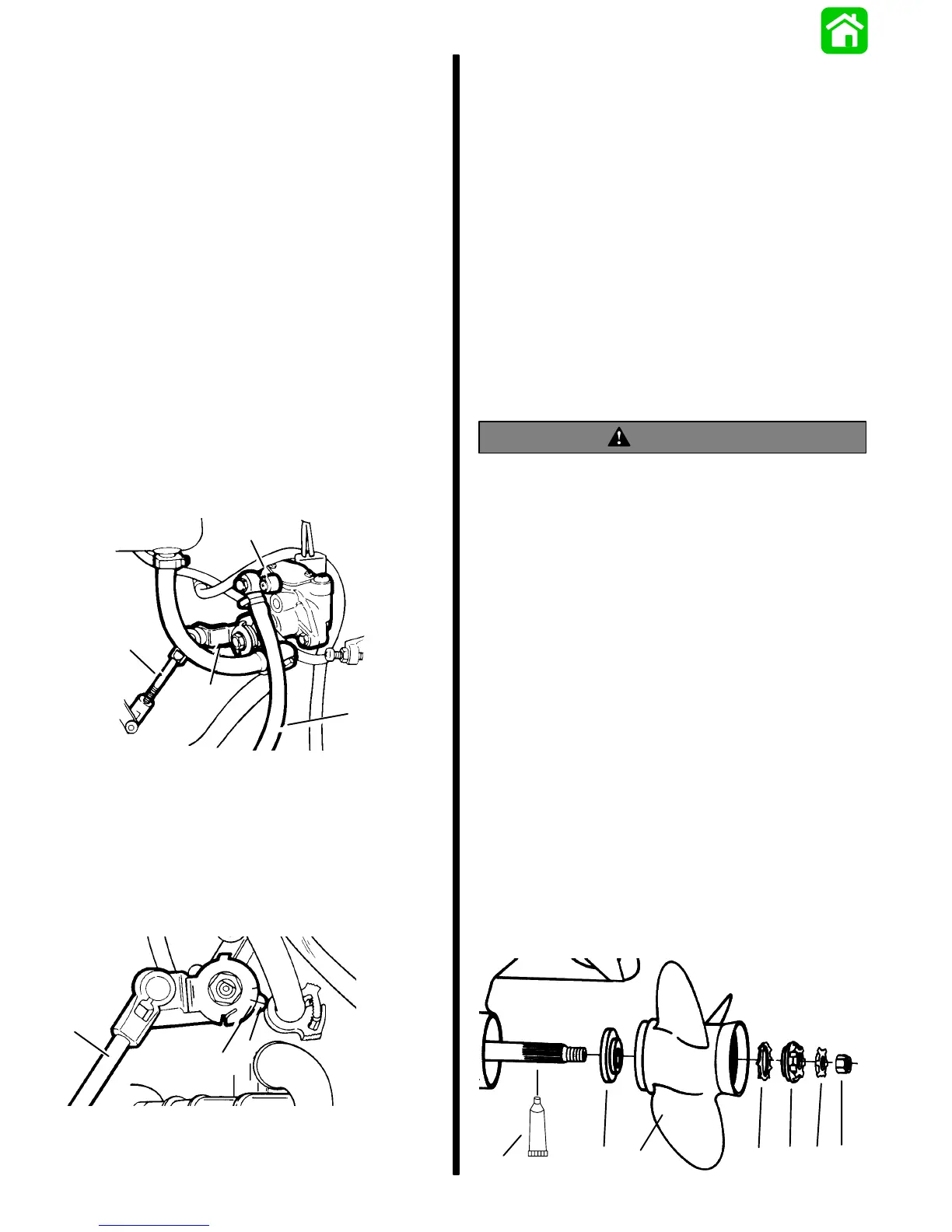

Propeller Installation

WARNING

When the propeller shaft is rotated and the en-

gine is in gear, there is the possibility for the en-

gine to crank over and start. To prevent this type

of accidental engine starting and possible seri-

ous injury caused from being struck by a rotating

propeller, always set the remote control into neu-

tral and remove spark plug leads when you are

servicing the propeller.

NOTE: To prevent the propeller hub from corroding

and seizing to the propeller shaft, especially in salt

water, always apply a coat of Quicksilver

Anti-Corrosion Grease to the entire shaft.

1. Set the remote control into neutral position.

2. Remove leads from spark plugs to prevent

engine from starting.

3. Coat the propeller shaft with Quicksilver Anti-

Corrosion Grease (g).

4. Install thrust washer (a), propeller (b), continuity

washer (c), thrust hub (d), tab washer (e), and

self locking nut (f) onto the shaft.

5. Torque propeller nut to 55 lb. ft. (75 N·m).

6. Bend three of the tabs into the propeller hub

grooves.

g

a

b

cd

ef

Loading...

Loading...