6B-44 - LOWER UNIT 90-824052R3 JUNE 2002

8. Move driveshaft up and down to determine end

play. Total up and down movement should be

0.00″ to 0.001″ (0.025mm). There should be no

preload on the bearing and the driveshaft must

rotate freely.

NOTE: DO NOT change shims under upper bearing

cup or pinion height will be changed.

9. Maintain the shims as previously set under the

upper driveshaft bearing cup.

10. Remove the upper bearing cup retainer with tool

91-43506, and remove cup [leave upper cup

shim(s) in place].

NOTE: A 0.001

″

(.025mm) change of shims under

the lower bearing cup will result in a 0.001

″

(0.025mm) change in driveshaft end play.

11. Place driveshaft end play shim(s), determined

from step 8, into gear housing and reinstall the

lower bearing cup.

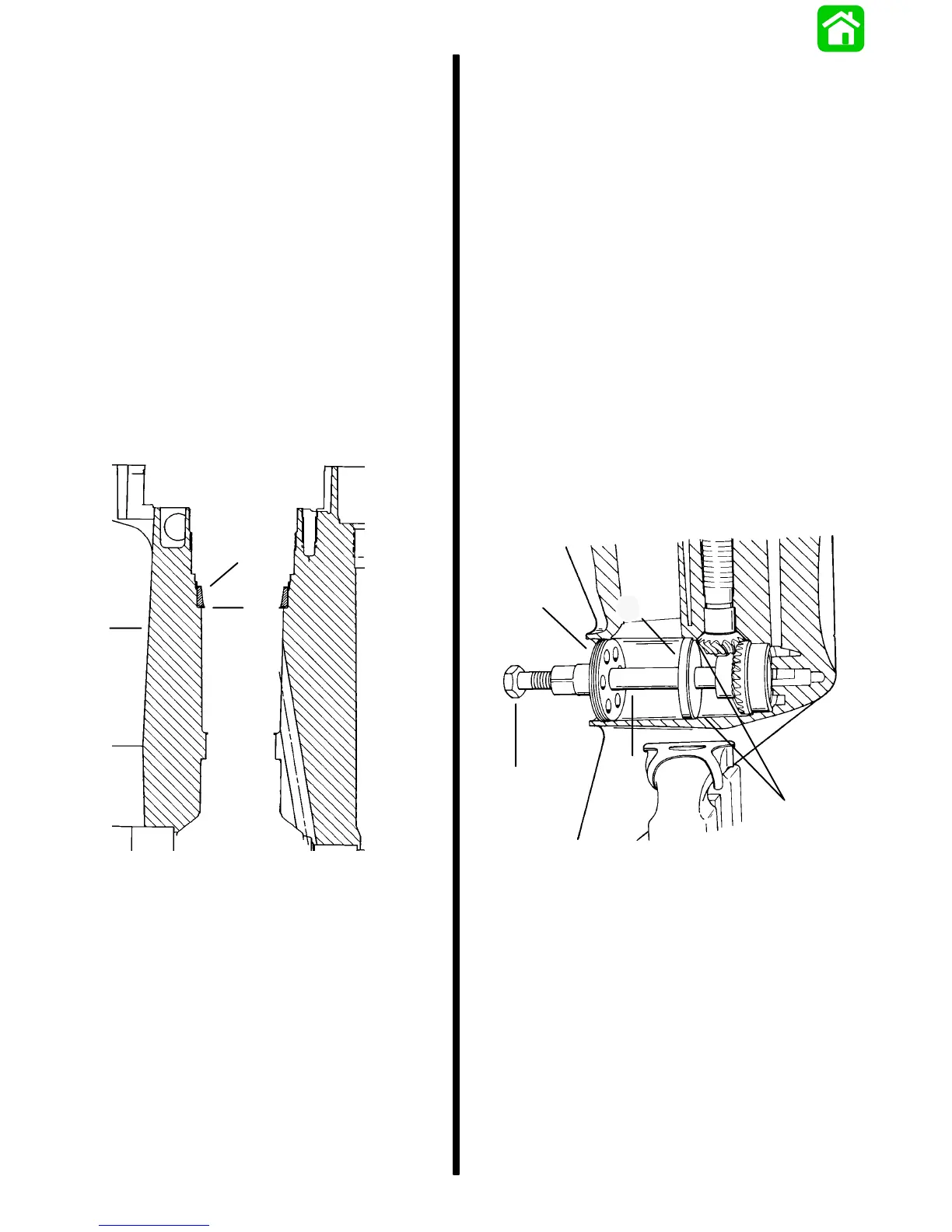

a

b

c

a - Driveshaft Housing

b - Lower Driveshaft Bearing Cup

c - Location of Driveshaft End Play Shims

12. Clean threads of driveshaft and apply Loctite

#271.

13. Apply gear oil to all bearing surfaces and install

driveshaft assembly, upper bearing cup and

retainer into the gear case. Tighten upper cup

retainer to a torque of 100 lb. ft. (135.5 N·m).

NOTE: If reverse gear backlash has not yet been

determined, do not use a new pinion nut until final

assembly.

14. Apply #271 Loctite to a NEW pinion nut and install

the pinion gear, washer and nut using procedures

detailed earlier in this section. Tighten pinion nut

to a torque of 85 lb. ft. (115 N

.

m).

15. Rotate driveshaft a few turns to verify that it turns

freely and recheck driveshaft end play.

Reverse Gear

DETERMINING REVERSE GEAR BACKLASH

NOTE: Although reverse gear backlash is not adjust-

able, it can be checked as follows:

1. Install Driver Tool (91-18605) into reverse gear

assembly.

2. Slide Pilot Ring (91-18603) over driver tool and

seat pilot ring against inner ledge in gear case.

3. Thread Retainer (91-18604) into gear case cover

nut threads.

4. Torque Screw (91-18602) to 45 Ib. in. (5.0 N·m)

against driver tool.

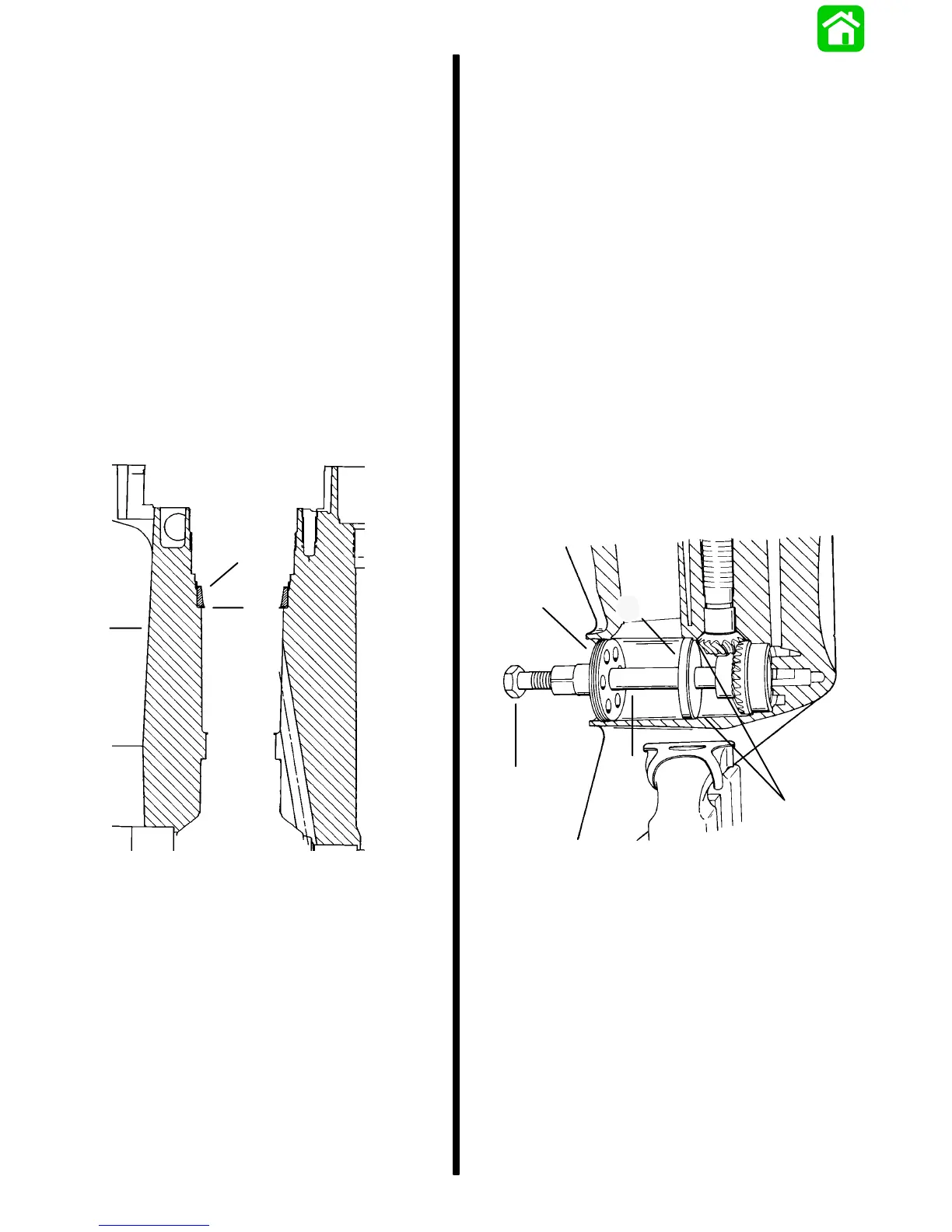

d

e

c

51884

b

a

a - Driver Tool (91-18605)

b - Pilot Ring (91-18603)

c - Inner Ledge

d - Retainer (91-18604)

e - Screw (91-18602) [Torque to 45 lb. in. (5.0 N·m)]

5. Thread stud adapter [from Bearing Preload Tool

(91-14311A1)] all the way onto stud.

6. Install: Backlash Indicator Tool (91-78473)

Dial Indicator Holder (91-89897)

Dial Indicator (91-58222A1)

7. Position dial indicator pointer on line marked “1”

on Backlash Indicator Tool, if gear ratio is 1.87:1

(15 teeth on pinion gear), or on line marked “2” on

Backlash Indicator Tool, if gear ratio is 2:1 (14

teeth on pinion gear).

Loading...

Loading...