6D-20 - LOWER UNIT 90-824052R3 JUNE 2002

5. Pull sliding clutch off propeller shaft.

6. Pull cam follower and clutch actuator rod out of

propeller shaft. DO NOT force cam follower

up-or-down or side-to-side when pulling from

propeller shaft.

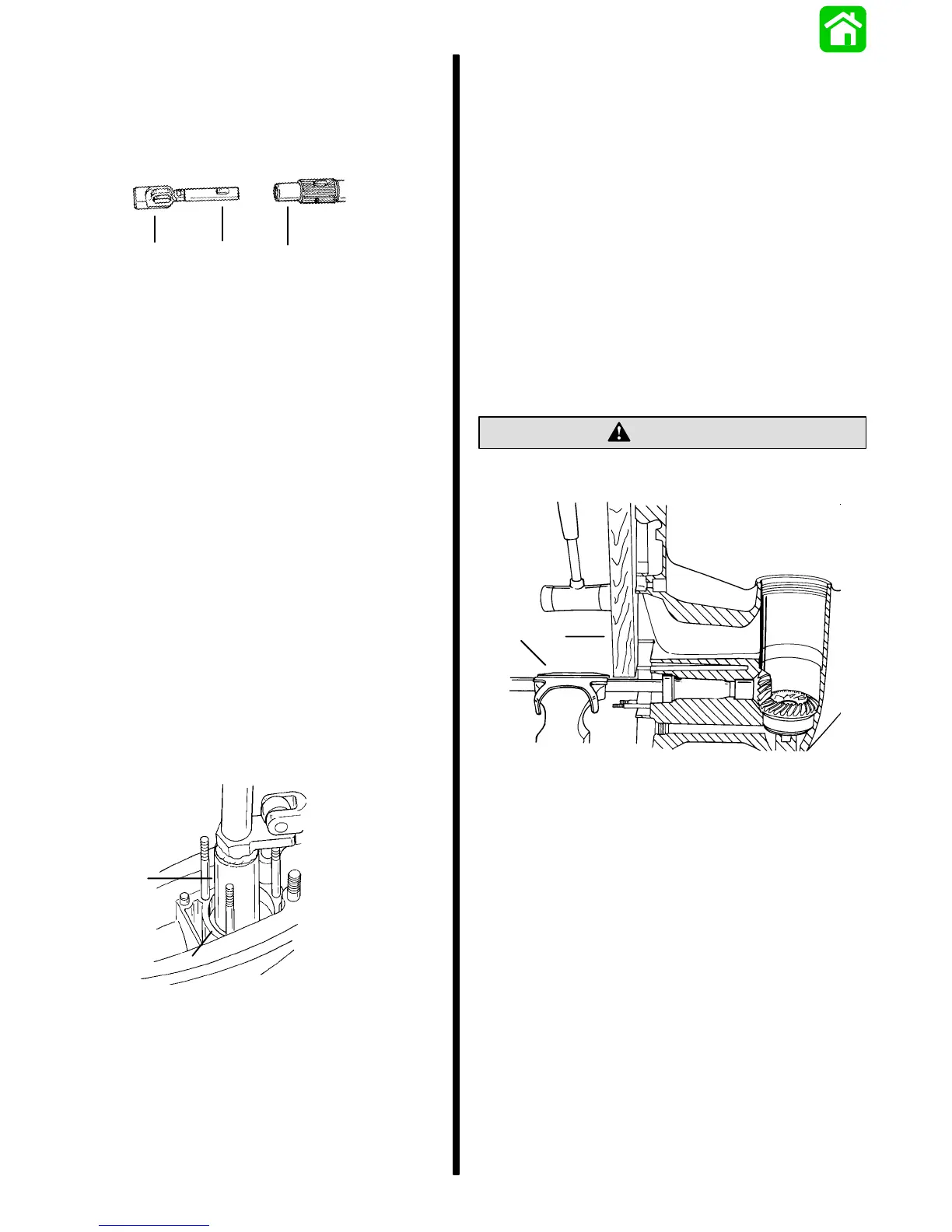

a

b

c

51864

a - Cam Follower

b - Clutch Actuator Rod

c - Propeller Shaft

7. Once cam follower and clutch actuator rod are

removed from propeller shaft, lift rod out of cam

follower.

Clutch Actuator Rod

CLEANING AND INSPECTION

1. Clean clutch actuator rod in solvent and dry with

compressed air.

2. Inspect actuator components for wear or

damage. Replace components as required.

Pinion Gear and Driveshaft

REMOVAL

1. Remove bearing retainer using Bearing Retainer

Tool (91-43506).

51865

a

b

a - Bearing Retainer

b - Bearing Retainer Tool (91-43506)

2. Place Driveshaft Holding Tool (91-34377A1) over

driveshaft splines.

3. Use a socket and flex handle to hold pinion nut.

(Pad area of gear housing where flex handle

will make contact to prevent damage to gear

housing.)

4. Use a socket and flex handle on Driveshaft

Holding Tool to loosen pinion nut. Remove pinion

nut and Driveshaft Holding Tool.

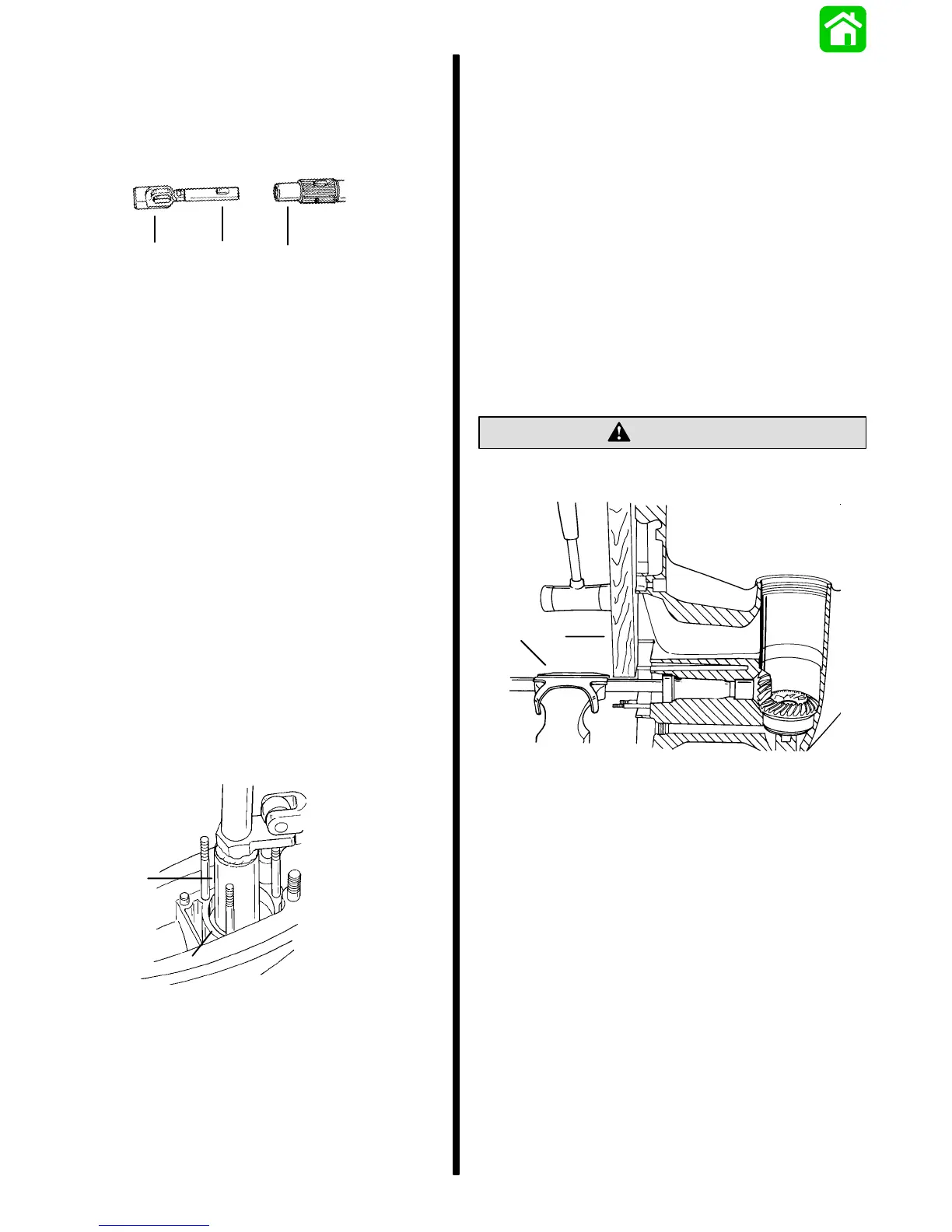

5. Remove gear housing from vise and re-position

it as shown. Be sure to use soft jaw vise covers

and clamp as close as possible to water pump

studs.

6. Place a block of wood on gear housing mating

surface. Use a mallet and carefully tap gear

housing away from driveshaft.

CAUTION

DO NOT strike gear housing hard with the mallet

or allow gear housing to fall.

b

a

51870

a - Wooden Block

b - Soft Jaw Vise Covers

7. Reach into gear housing and remove pinion gear

and forward gear assembly.

8. After driveshaft is removed from gear case,

remove and retain shim(s) that were located

under upper tapered driveshaft bearing.

9. If inspection determines that replacement of

driveshaft tapered bearing is required, remove

bearing from driveshaft as follows:

a. Position driveshaft in a vise; DO NOT tighten

vise jaws against shaft.

Loading...

Loading...