4A-42 - POWERHEAD 90-824052R3 JUNE 2002

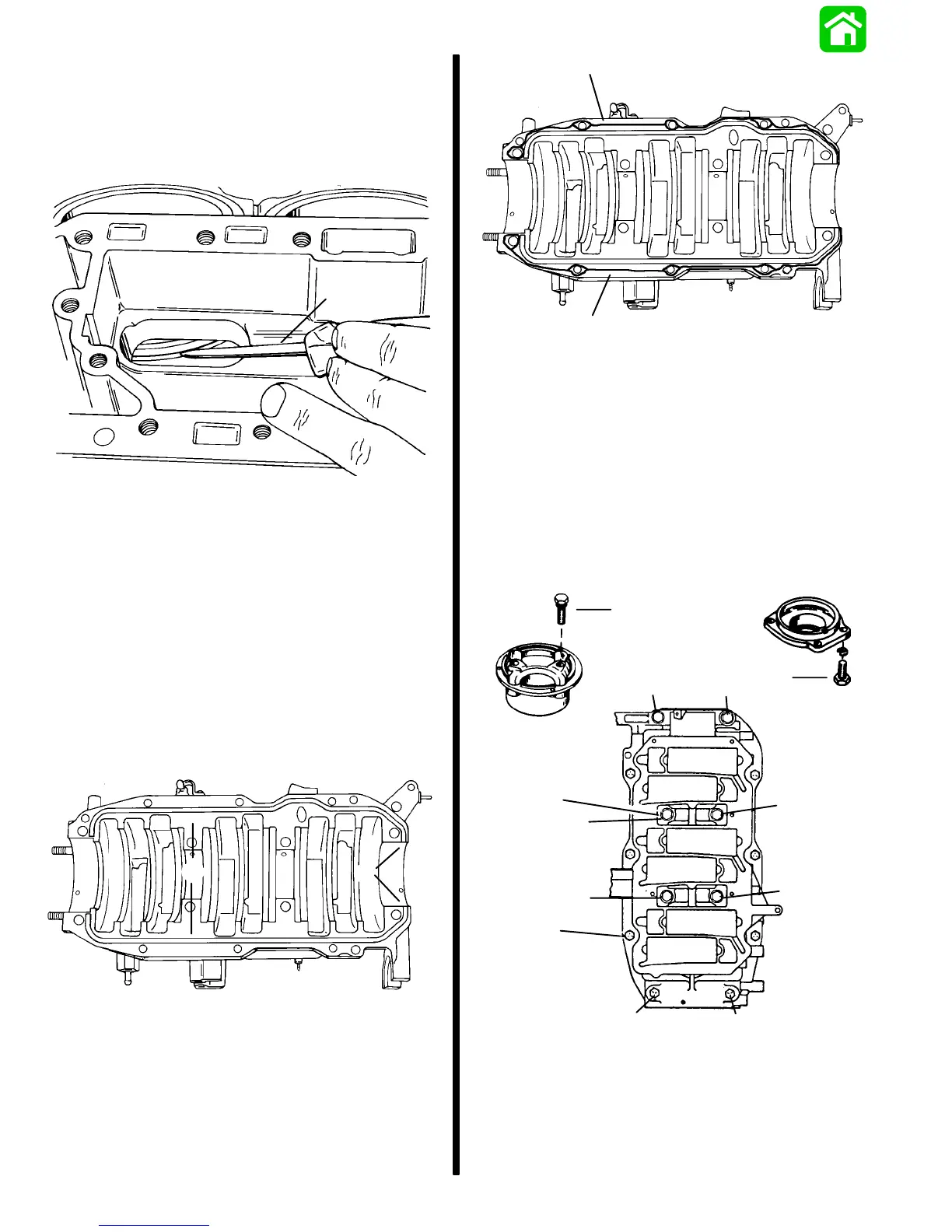

14. Verify that no piston rings were broken during

installation by pressing in on each piston ring thru

exhaust port using a screwdriver. If no spring

tension exists (ring fails to return to position), it’s

likely ring is broken and must be replaced.

51852

a

a - Screwdriver

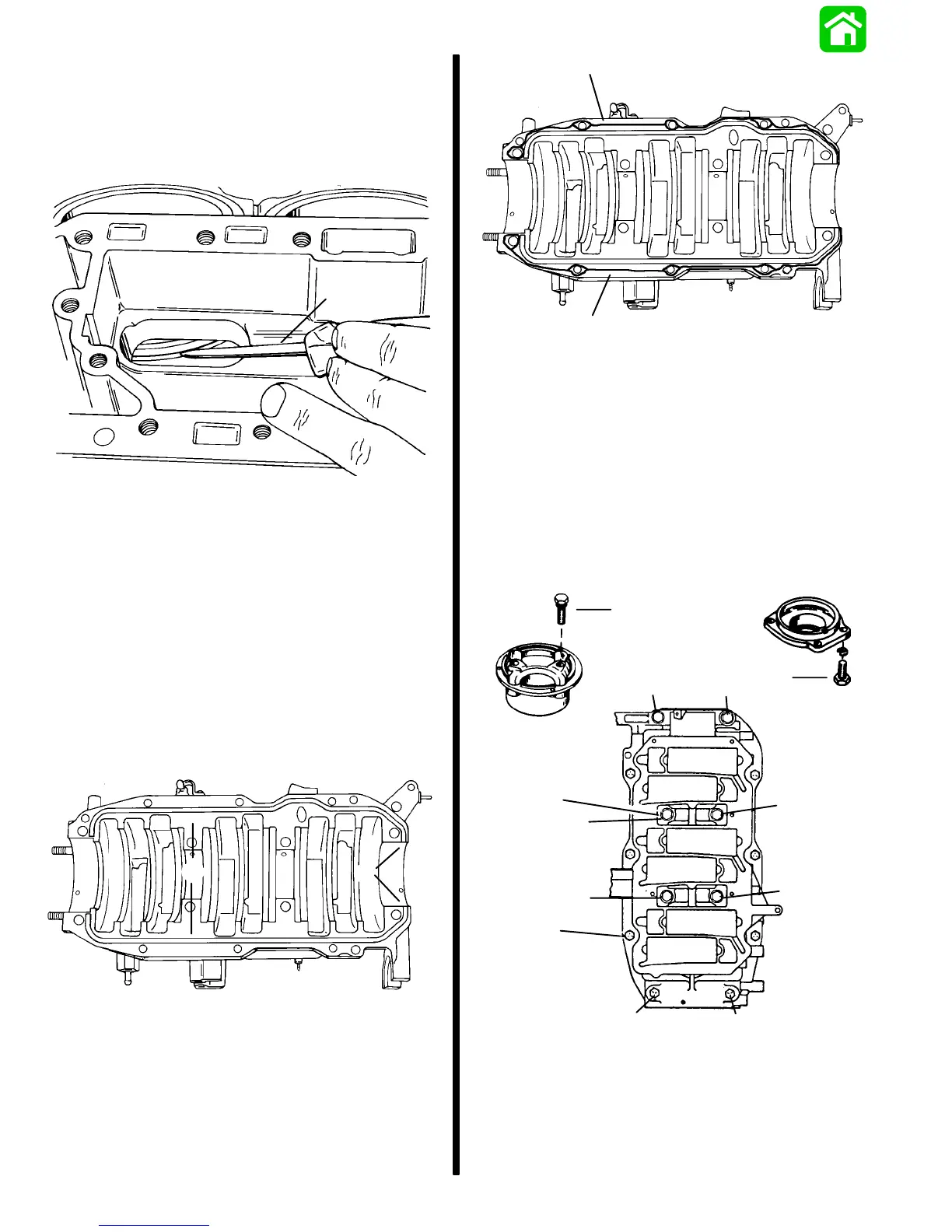

Crankcase Cover Installation

(Standard and High Performance

Models)

1. Thoroughly remove all oil from mating surfaces of

crankcase cover and cylinder block with Loctite

Primer ‘T’ (92-59327-1).

2. Install gasket strips into grooves in crankcase

cover. Trim end of each gasket strip flush with

edge of cover as shown.

b

a

51852

a - Gasket Strips

b - Edge of Cover

3. Apply a thin, even coat of Loctite Master Gasket

#203 on mating surfaces of crankcase cover and

cylinder block.

a

a

a - Loctite Master Gasket (92-12564-1)

4. Place crankcase cover in position on cylinder

block. Turn the 8 center main bolts in a LITTLE at

a time, (following torque sequence) compressing

crankshaft seal rings until crankshaft cover has

been drawn down to cylinder block. Tighten eight

bolts (a) evenly in three progressive steps

(following torque sequence).

5. Install remaining crankcase cover flange bolts.

6. Tighten end cap bolts to specified torque.

a

b

c

d

8

7

4

2

6

5

3

1

a - Upper End Cap Bolts – Torque to 150 lb. in. (17.0 N·m)

b - Lower End Cap Bolts – Torque to 80 lb. in. (9.0 N·m)

c - Add Light Oil to Threads and Bolt Face – 8 Bolts

(3/8 in.-18) Torque to 38 lb. ft. (51.5 N·m)

d - Bolts (5/16 in.-18) Torque to 15 lb. ft. (20.5 N·m)

Loading...

Loading...