90-824052R3 JUNE 2002 LOWER UNIT - 6A-55

CAUTION

A visual inspection of impeller drive key MUST

BE made to determine that drive key is on flat of

driveshaft after impeller is installed. If key has

moved off flat of driveshaft, repeat Steps 6 and 7.

7. Slide impeller down driveshaft to impeller drive

key. Align drive key with keyway in the center hub

of impeller, and slide impeller over drive key.

8. If removed, install new water pump insert into

pump cover as follows:

a. Apply Perfect Seal to water pump insert area

of pump cover.

b. Install water pump insert into pump cover.

Verify that tab on insert enters recess in pump

cover.

c. Wipe any excess Perfect Seal from insert and

cover.

NOTE: If 2 holes were drilled in top of water pump

cover to aid in removal of insert, fill holes with RTV

Sealer or equivalent. Allow to cure, 24 hours prior to

operating engine.

9. Install water tube seal into pump cover, being

sure that plastic side of seal goes into cover first.

10. Reinstall water tube guide into water pump cover.

11. Apply a light coat of Quicksilver 2-4-C w/Teflon

Marine Lubricant inside of water pump insert.

12. Position assembled water pump cover over

driveshaft and lower over water pump studs.

Rotate driveshaft in a clockwise direction (viewed

from top), while pushing down on pump cover to

ease impeller entry into cover.

13. Install water pump cover retainer washers, nuts

and bolt.

CAUTION

DO NOT over-torque nuts and bolt, as this could

cause cover to crack during operation.

14. Torque water pump nuts to 50 Ib. in. (5.5 N·m),

and water pump bolt to 35 Ib. in. (4.0 N·m).

15. Install centrifugal slinger over drive shaft and

down against pump cover.

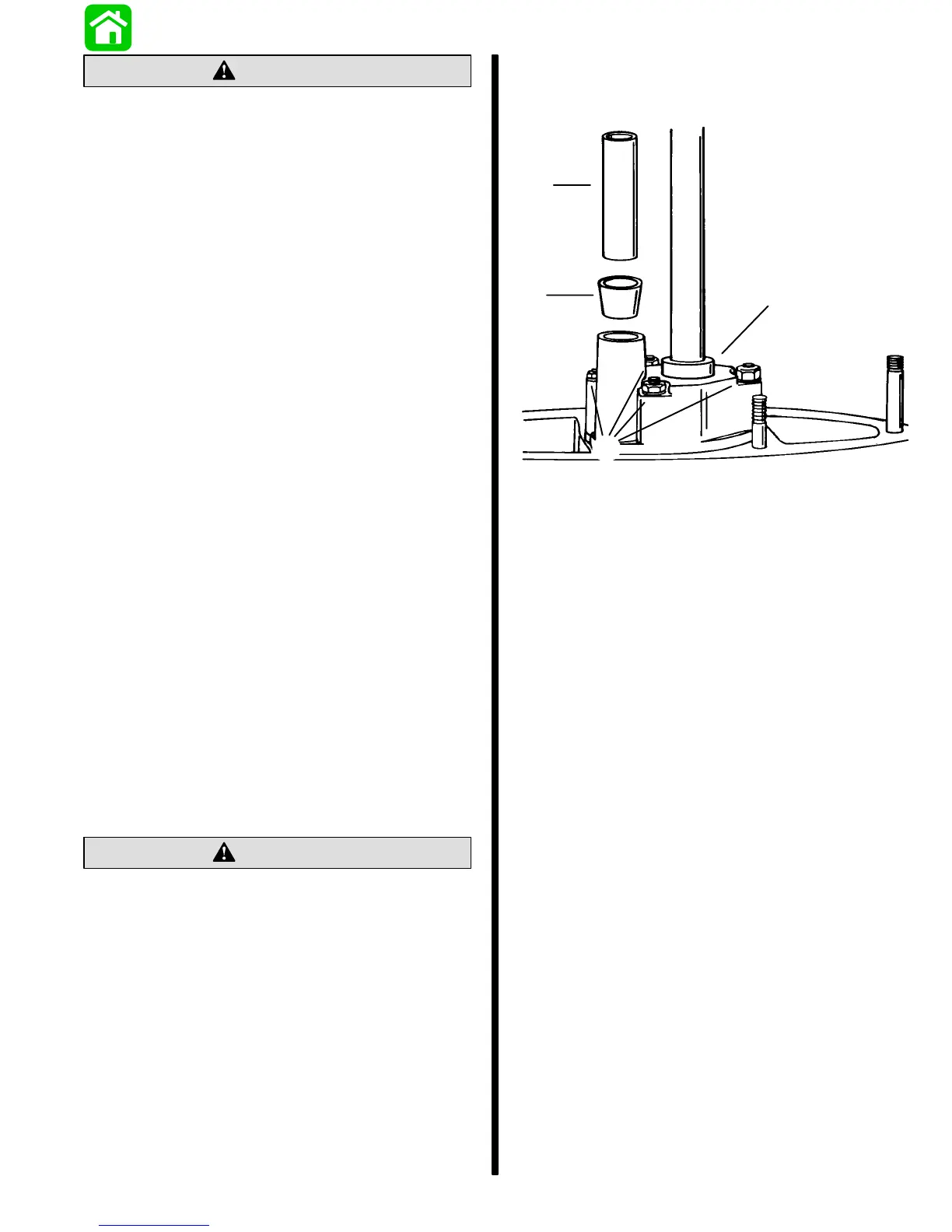

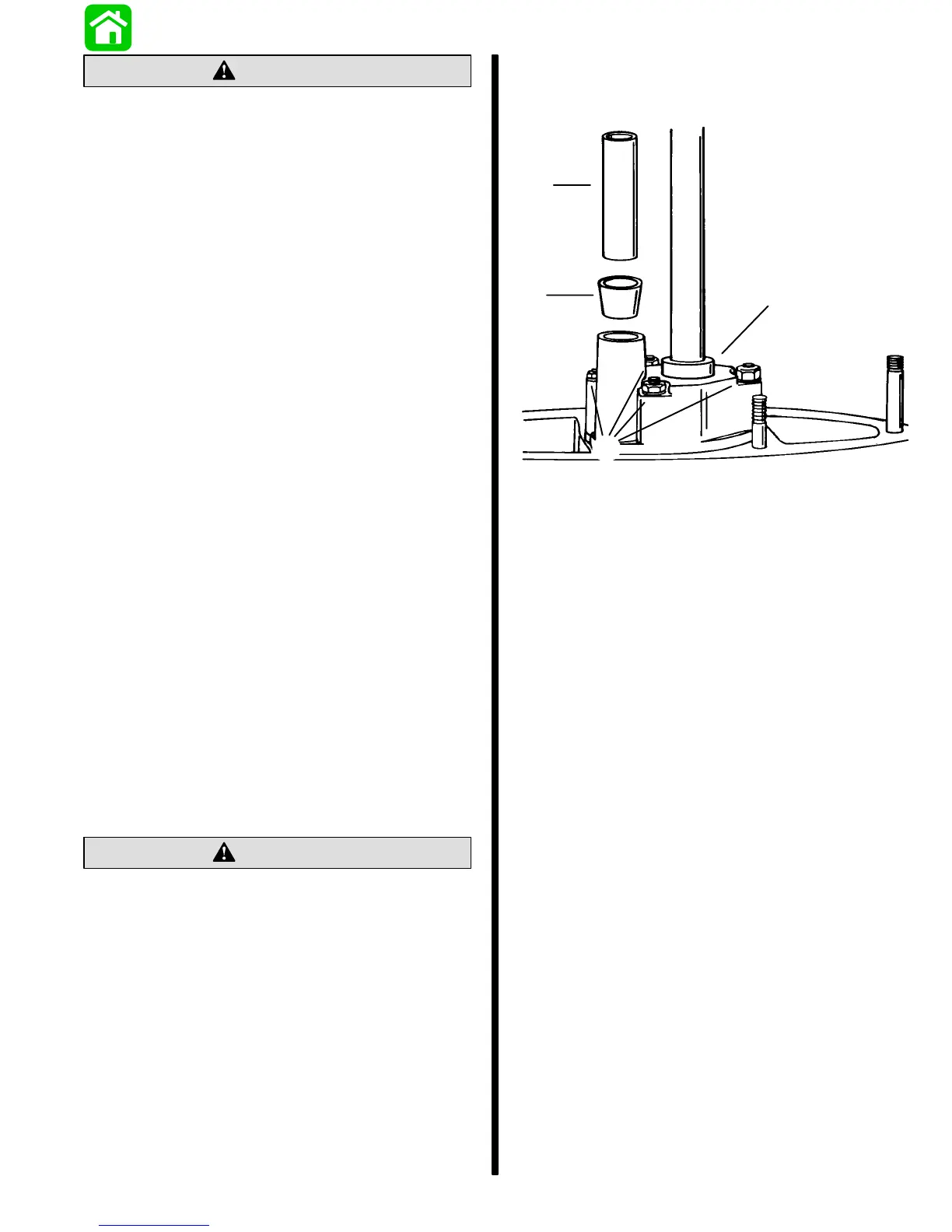

b

c

a

d

51874

a - Centrifugal Slinger (if equipped)

b - Water Tube Guide

c - Water Tube Seal

d - Nuts, Bolts and Washers

Gear Lubricant Filling Instructions

1. Remove any gasket material from “Fill” and

“Vent” screws and gear housing.

2. Install new gaskets on “Fill” and “Vent” screws.

IMPORTANT: Never apply lubricant to gear

housing without first removing “Vent” screw, or

gear housing cannot be filled because of trapped

air. Fill gear housing ONLY when housing is in a

vertical position.

IMPORTANT: All CLE, Sport Master and Torque

Master gear cases should use Quicksilver Hi-

Performance Gear Lube (92-816026A4).

3. Slowly fill housing thru “Fill” hole with Quicksilver

Super Duty Lower Unit Lubricant until lubricant

flows out of “Vent” hole and no air bubbles are

visible.

4. Install “Vent” screw into “Vent” hole.

IMPORTANT: DO NOT lose more than one fluid

ounce (30cc) of gear lubricant while reinstalling

“Fill” screw.

5. Remove grease tube (or hose) from “Fill” hole

and quickly install “Fill” screw into “Fill” hole.

Loading...

Loading...