3C-26 - FUEL SYSTEMS 90-824052R3 JUNE 2002

Results: Fuel flows freely from pulse pump inlet

hose. Remove, disassemble, and inspect

pulse fuel pump (Section 3A).

IMPORTANT: All fragments of failed pump must

be located before re-assembly.

No or low fuel flow from pulse pump inlet hose. Check

for restrictions, holes, or loose connections from fuel

supply.

NOTE: Inspect anti-siphon valve on tank.

Final Filter Check and

De-pressurizing EFI System

Procedures

Purpose: Checking the final filter for obstructions,

damage etc. eliminates this component as a

possible source of restriction in the system.

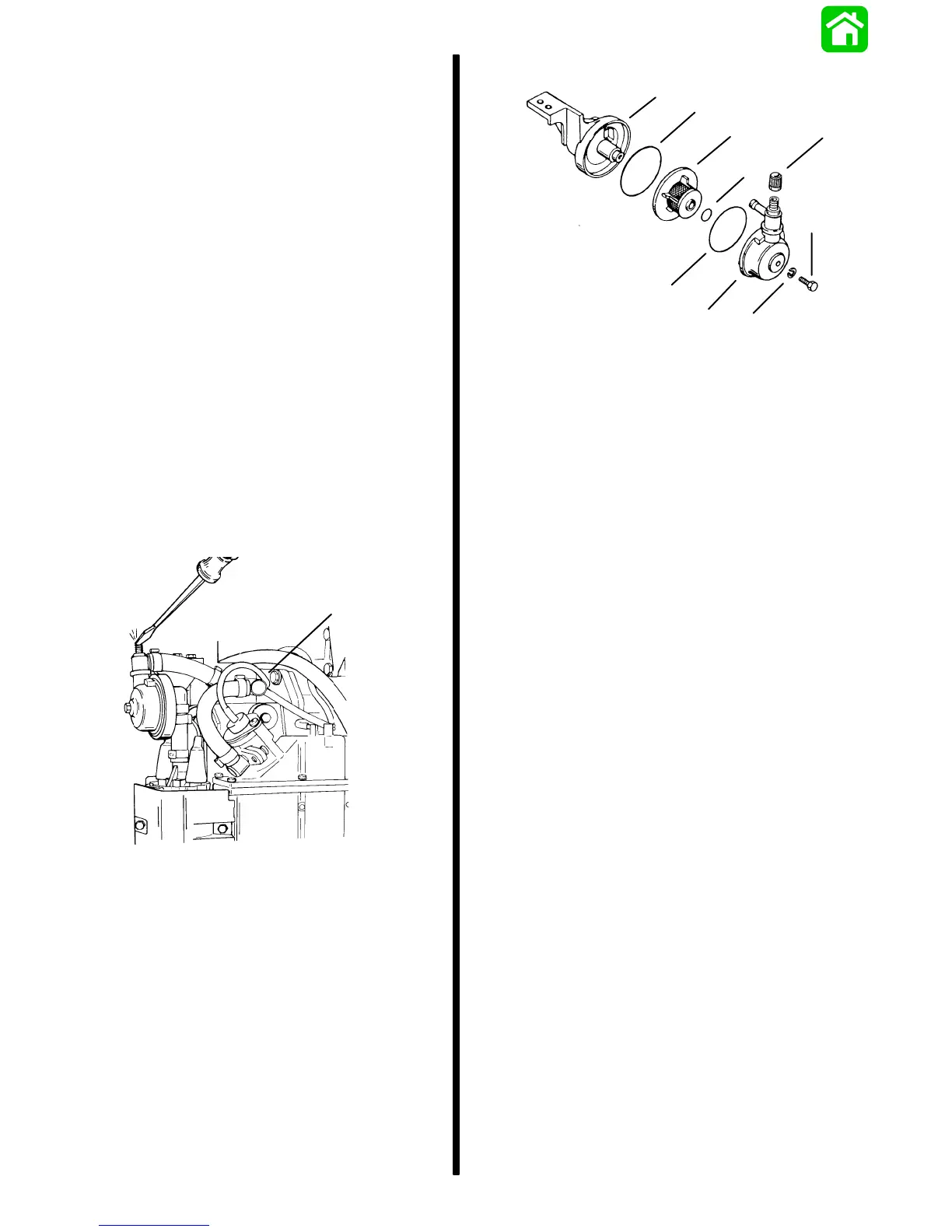

Procedure: STEP 1: De-pressurize EFI fuel

system by wrapping a clean cloth around

pressure port valve and inserting tip of

screwdriver into valve, depressing valve

core. Let fuel drain from valve.

51796

a

a - Pressure Port may be located at this location on some

models.

NOTE: Pressure port valve may be located on

manifold fitting on some models.

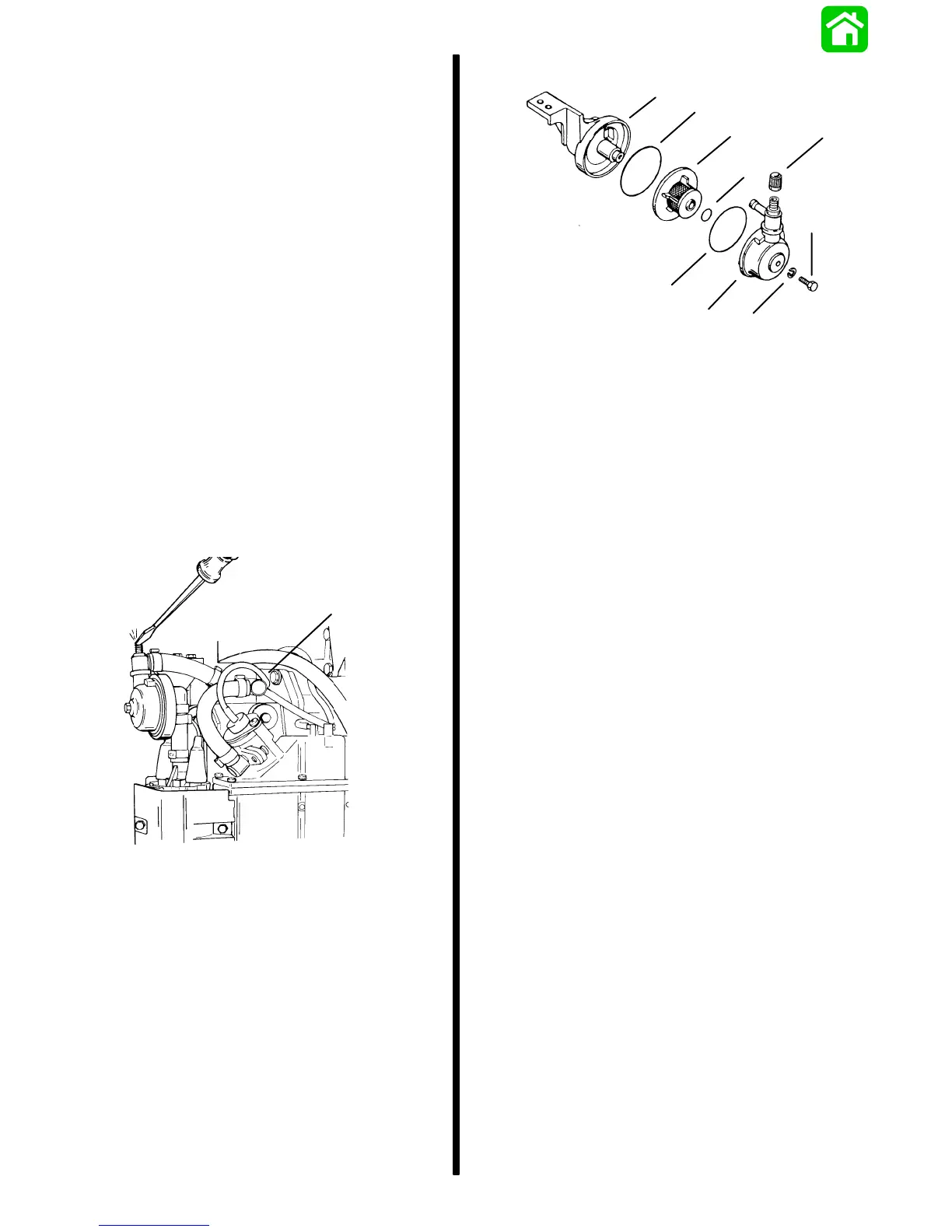

STEP 2: Remove filter cap.

a

b

c

d

h

g

f

e

b

51796

a - Filter Housing

b - Large O-ring

c - Filter Element

d - Small O-ring

e - Filter Cap

f - Lockwasher

g - Screw

h - Cap

STEP 3: Look at filter for plugging, damage or

other signs of unusual condition.

Results: Filter is clogged with debris. Clean with

carburetor cleaner and compressed air or

replace. Recheck fuel pressure.

Filter is O.K. Pressure still below 36 psi (248 kPa).

Perform fuel pressure regulator test.

Loading...

Loading...