90-824052R3 JUNE 2002 LOWER UNIT - 6D-37

8. Move gear housing up toward driveshaft hous-

ing, while aligning shift shaft splines and water

tube with water tube guide (in water pump cover).

9. Place flat washers onto studs (located on either

side of driveshaft housing). Start a nut on these

studs and tighten finger-tight.

10. Start bolt at rear of gear housing inside trim tab

recess. DO NOT tighten bolt at this time.

11. Recheck shift shaft spline engagement and

correct if necessary.

IMPORTANT: Do not force gearcase up into place

with attaching nuts.

12. Evenly tighten 2 nuts which were started in Step

9. Torque to listing in “Torque Specifications,”

preceding.

13. After 2 nuts (located on either side of driveshaft

housing) are tightened, check shift operation as

follows:

a. Place guide block anchor pin into forward

gear position. Rotate flywheel clockwise

(viewed from top); propeller shaft should

rotate clockwise.

b. Place guide block anchor pin into neutral

position. Propeller shaft should rotate freely

clockwise/counterclockwise.

c. Place guide block anchor pin into reverse

gear position. Rotate flywheel clockwise

(viewed from top); propeller shaft should

rotate counterclockwise.

IMPORTANT: lf shifting operation is not as

described, preceding, the gear housing must be

removed and the cause corrected.

14. Install washers and nuts onto studs (located on

bottom center of anti-cavitation plate). Torque to

listing in “Torque Specifications,” preceding.

15. Install special flat washer and nut on stud at lead-

ing edge of driveshaft housing. Torque to listing

in “Torque Specifications,” preceding.

16. Torque bolt (started in Step 10) to listing in

“Torque Specifications,” preceding.

17. Install trim tab, adjust to position in which it had

previously been installed, and tighten securely.

18. Install plastic cap into trim tab bolt opening at rear

edge of driveshaft housing.

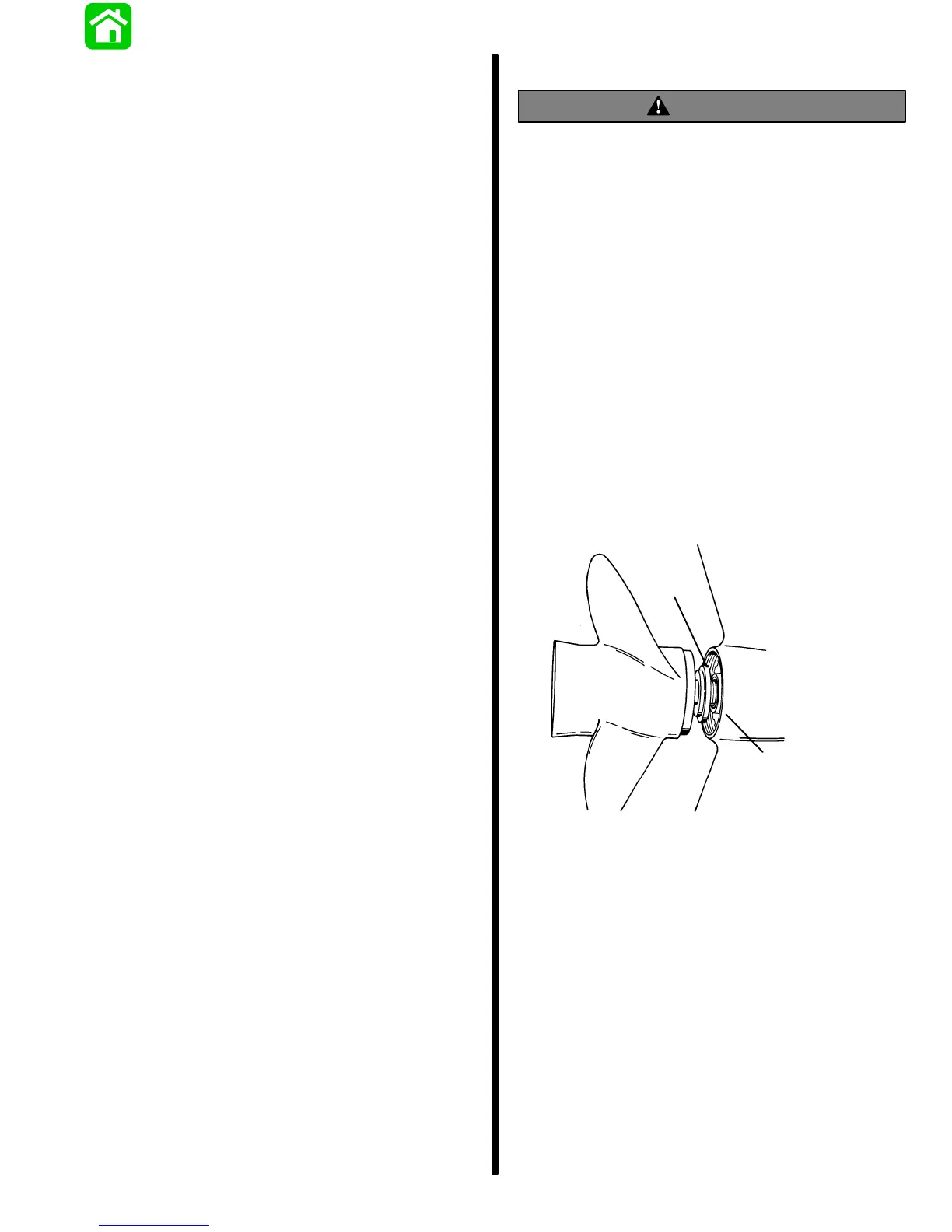

Propeller Installation

WARNING

When installing or removing propeller, because

of the engine’s ease in starting, be sure that the

remote control is in neutral position and that the

key switch is “OFF.” Place a block of wood

between the anti-cavitation plate and propeller to

prevent accidental starting and to protect hands

from propeller blades while removing or

installing nut.

1. To aid in future removal of the propeller, liberally

coat the propeller shaft splines with one of the

following Quicksilver products:

-- Anti-Corrosion Grease (92-78376A6)

-- Special Lubricant 101 (92-13872A1)

-- 2-4-C Marine Lubricant (92-90018A12)

-- Perfect Seal (92-34227--1)

2. Place forward thrust hub over propeller shaft with

shoulder side toward propeller.

3. Place propeller on propeller shaft and slide it up

against thrust hub.

a

b

51866

a - Forward Thrust Hub

b - Propeller Shaft

4. Place continuity washer (if equipped) onto

shoulder of rear thrust hub.

5. Place rear thrust hub, tab washer and propeller

nut on propeller shaft.

6. Thread propeller nut onto propeller shaft until nut

is recessed into tab washer.

7. After propeller nut is recessed into tab washer,

tighten nut securely [minimum of 55 Ib. ft. (74.5

N·m) torque].

Loading...

Loading...