90-824052R3 JUNE 2002 LOWER UNIT - 6A-57

Propeller Installation

WARNING

When installing or removing propeller, because

of the engine’s ease in starting, be sure that the

remote control is in neutral position and that the

key switch is “OFF.” Place a block of wood

between the anti-cavitation plate and propeller to

prevent accidental starting and to protect hands

from propeller blades while removing or

installing nut.

1. To aid in future removal of the propeller, liberally

coat the propeller shaft splines with one of the

following Quicksilver products:

– Anti-Corrosion Grease (92-78376A6)

-- Special Lubricant 101 (92-13872A1)

-- 2-4-C Marine Lubricant (92-90018A12)

-- Perfect Seal (92-34227--1)

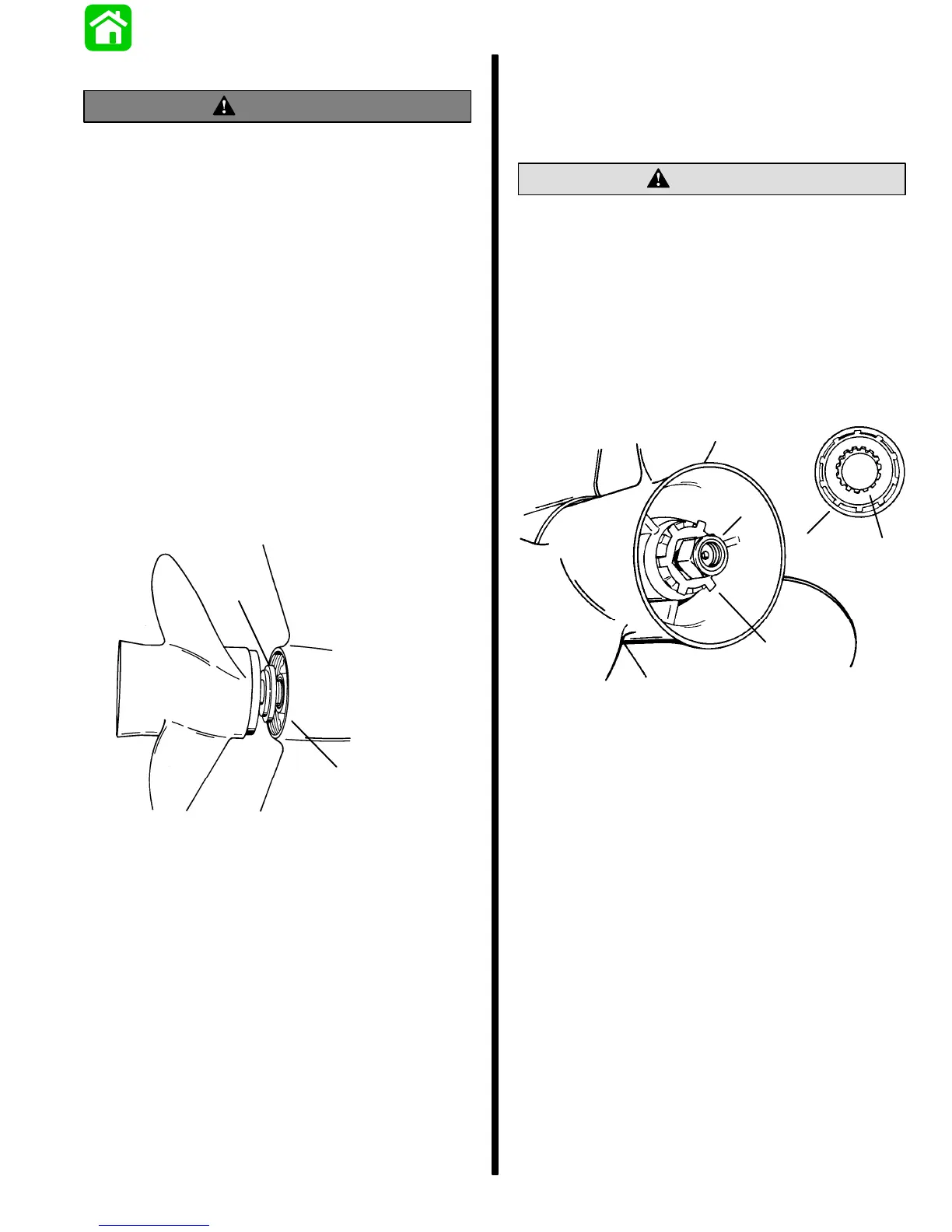

2. Place forward thrust hub over propeller shaft with

shoulder side toward propeller.

3. Place propeller on propeller shaft and slide it up

against thrust hub.

b

51866

a

a - Forward Thrust Hub

b - Propeller Shaft

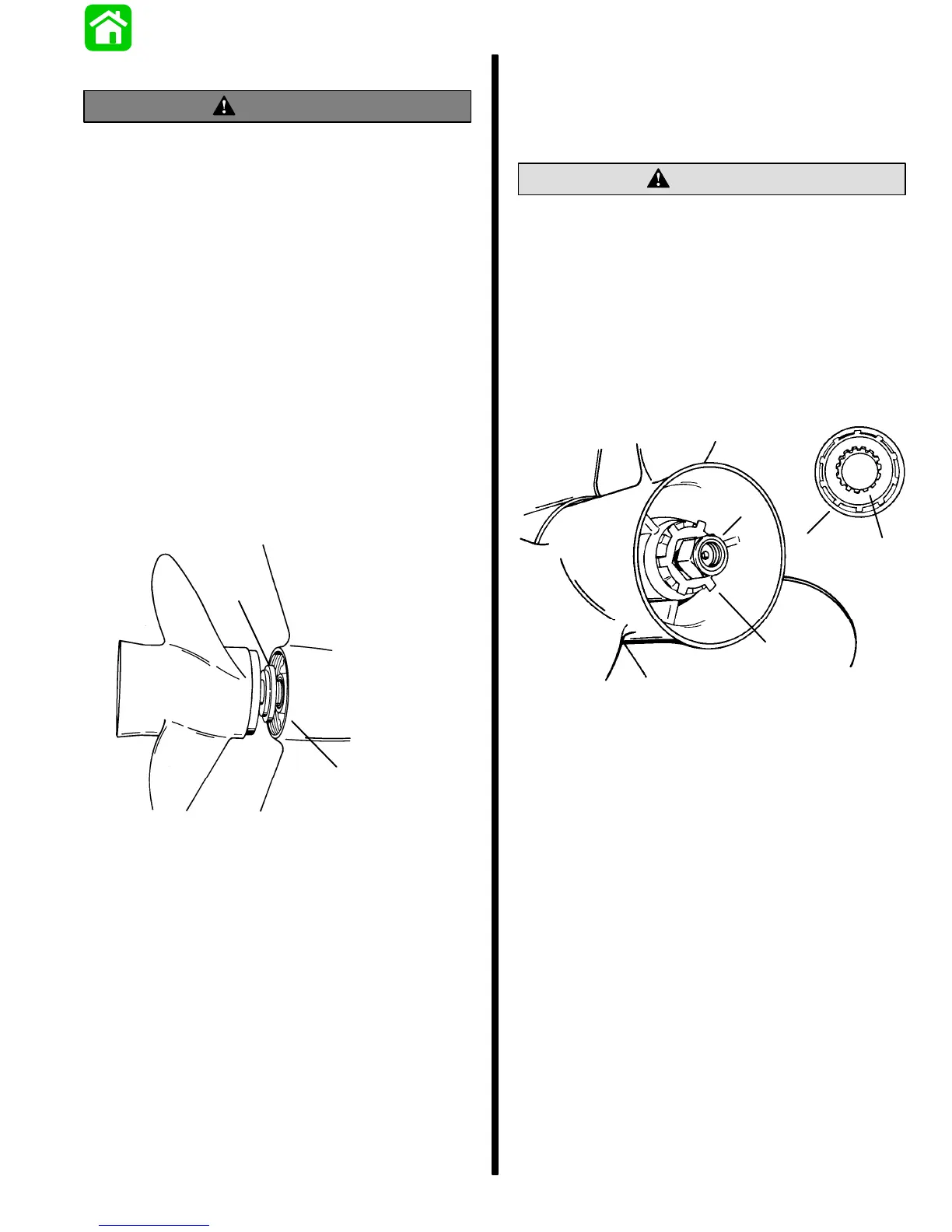

4. Place continuity washer (if equipped) onto

shoulder of rear thrust hub.

5. Place rear thrust hub, tab washer and propeller

nut on propeller shaft.

6. Thread propeller nut onto propeller shaft until nut

is recessed into tab washer.

7. After propeller nut is recessed into tab washer,

tighten nut securely [minimum of 55 Ib. ft. (74.5

N·m) torque].

8. Bend 3 of the tabs of tab washer down in grooves

of rear thrust hub to secure propeller nut. (If tab

washer tabs do not align with slots, continue to

tighten propeller nut to obtain alignment. DO

NOT loosen nut to align tabs.)

CAUTION

DO NOT misinterpret propeller shaft movement

with propeller movement. If propeller and

propeller shaft together move forward-and-aft,

this is normal; how- ever, propeller should not

move forward-and-aft on propeller shaft.

9. After first use, retighten propeller nut and again

secure with tab washer (Steps 7 and 8, preced-

ing). Propeller should be checked periodically for

tightness, particularly if a stainless steel propeller

is used.

d

c

a

b

51866

a - Continuity Washer (if Equipped)

b - Rear Thrust Hub

c - Tab Washer

d - Propeller Nut

Loading...

Loading...