90-824052R3 JUNE 2002 LOWER UNIT - 6B-35

3. Inspect driveshaft needle bearing surface (area

just above pinion gear splines) for pitting,

grooves, scoring, uneven wear and/or discolor-

ation from overheating. Replace driveshaft and

driveshaft needle bearing, if any of the preceding

conditions are found.

4. Inspect driveshaft to crankshaft splines for wear.

Replace driveshaft if wear is excessive.

5. Inspect tapered bearing race for pitting, grooves,

scoring, uneven wear and discoloration from

overheating. Replace tapered bearing and race

as a set, if any of the preceding conditions are

found.

6. Inspect driveshaft for groove(s) where water

pump base oil seals contact shaft. Replace drive-

shaft if groove(s) are found.

Reverse Gear

REMOVAL AND DISASSEMBLY

NOTE: Reverse gear can be removed from gear

housing only after driveshaft and pinion gear have

been removed.

NOTE: Cautiously applying heat to both sides of

gearcase where reverse gear assembly is located

will aid in removal of reverse gear assembly and

bearing cup adapter.

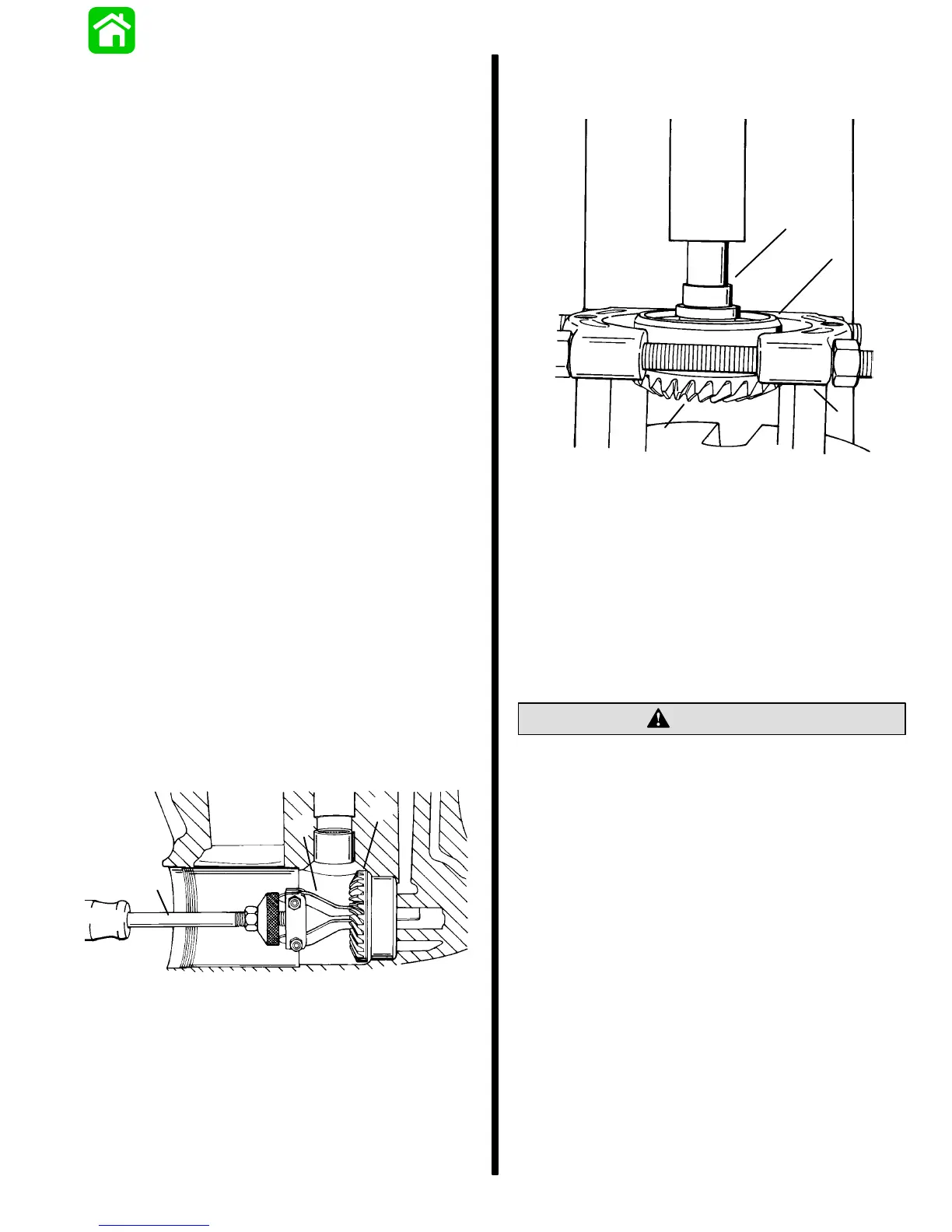

1. Use a slide hammer and two-jaw puller to remove

reverse gear bearing assembly.

IMPORTANT: DO NOT remove ball bearing or

needle bearing from reverse gear unless replace-

ment of bearings is required. Bearings cannot be

reused after they have been removed.

a

c

b

a - Slide Hammer

b - Two-Jaw Puller

c - Reverse Gear Bearing Assembly

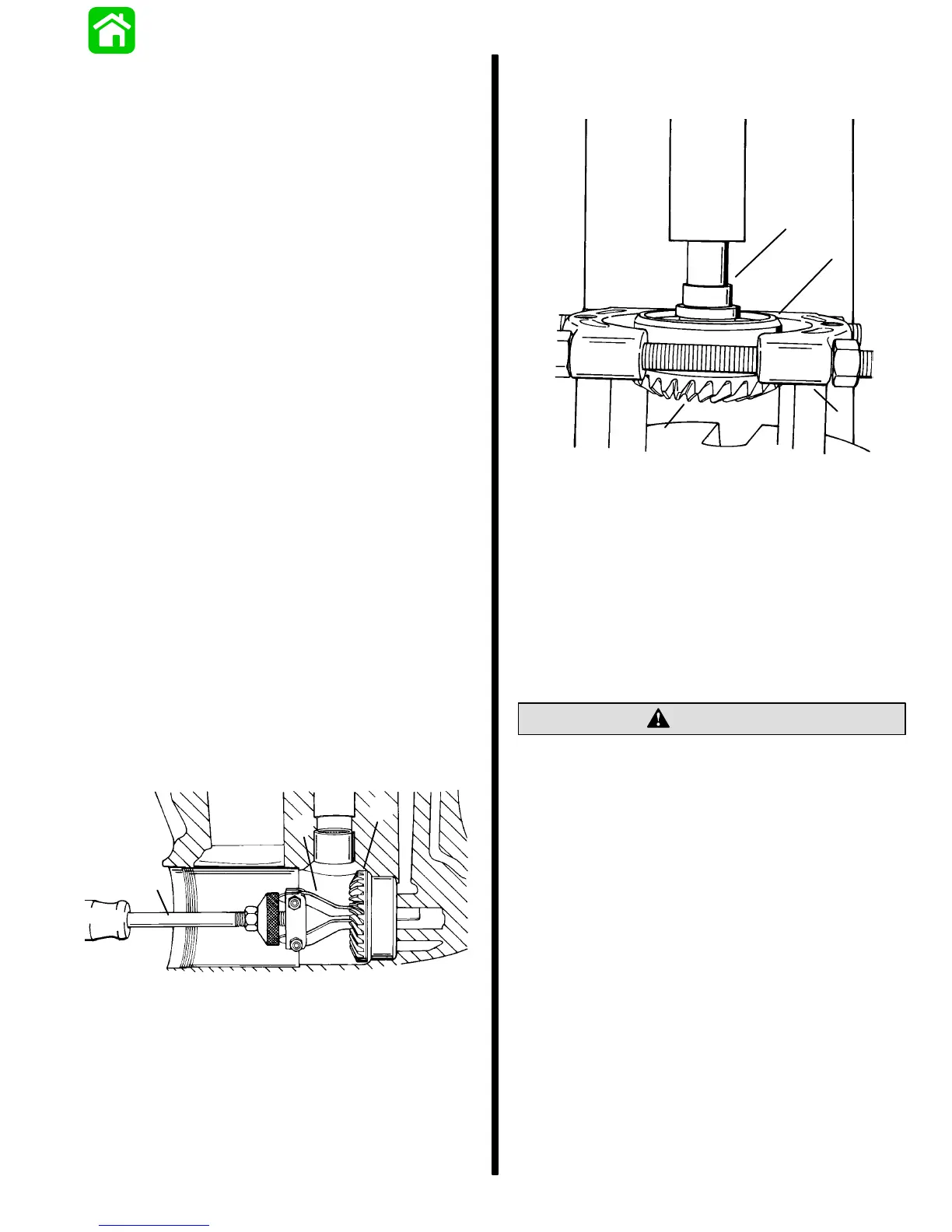

2. If inspection determines that replacement of

reverse gear ball bearing is required, then:

a. Install Universal Puller Plate (91-37241)

between reverse gear and ball bearing.

b. Place reverse gear, bearing and puller plate

on a press and press gear out of bearing

using a suitable mandrel.

d

a

b

c

51884

a - Reverse Gear Ball Bearing

b - Universal Puller Plate

c - Reverse Gear

d - Mandrel

3. If inspection determines that replacement of pro-

peller shaft needle bearing in REVERSE gear is

required, place REVERSE gear in press and use

mandrel 91-36569 to press bearing out of gear.

CLEANING AND INSPECTION

CAUTION

DO NOT spin bearings dry with compressed air,

as this could cause bearing to score.

1. Clean reverse gear and bearing with solvent and

dry with compressed air.

2. Inspect gear teeth for pitting, grooves, scoring,

uneven wear and for discoloration (from over-

heating). Replace gear if any of these conditions

are found.

3. Check clutch jaws on reverse gear for damage.

Replace reverse gear if damage is found.

4. Inspect ball bearing race for pitting, grooves,

scoring, uneven wear and discoloration (from

overheating). Replace ball bearing (on reverse

gear) if any of these conditions are found.

5. To determine condition of propeller shaft needle

bearings (in reverse gear), inspect propeller shaft

reverse gear needle bearing surface as outlined

in “Propeller Shaft Inspection.”

Loading...

Loading...