90-824052R3 JUNE 2002 LOWER UNIT - 6B-51

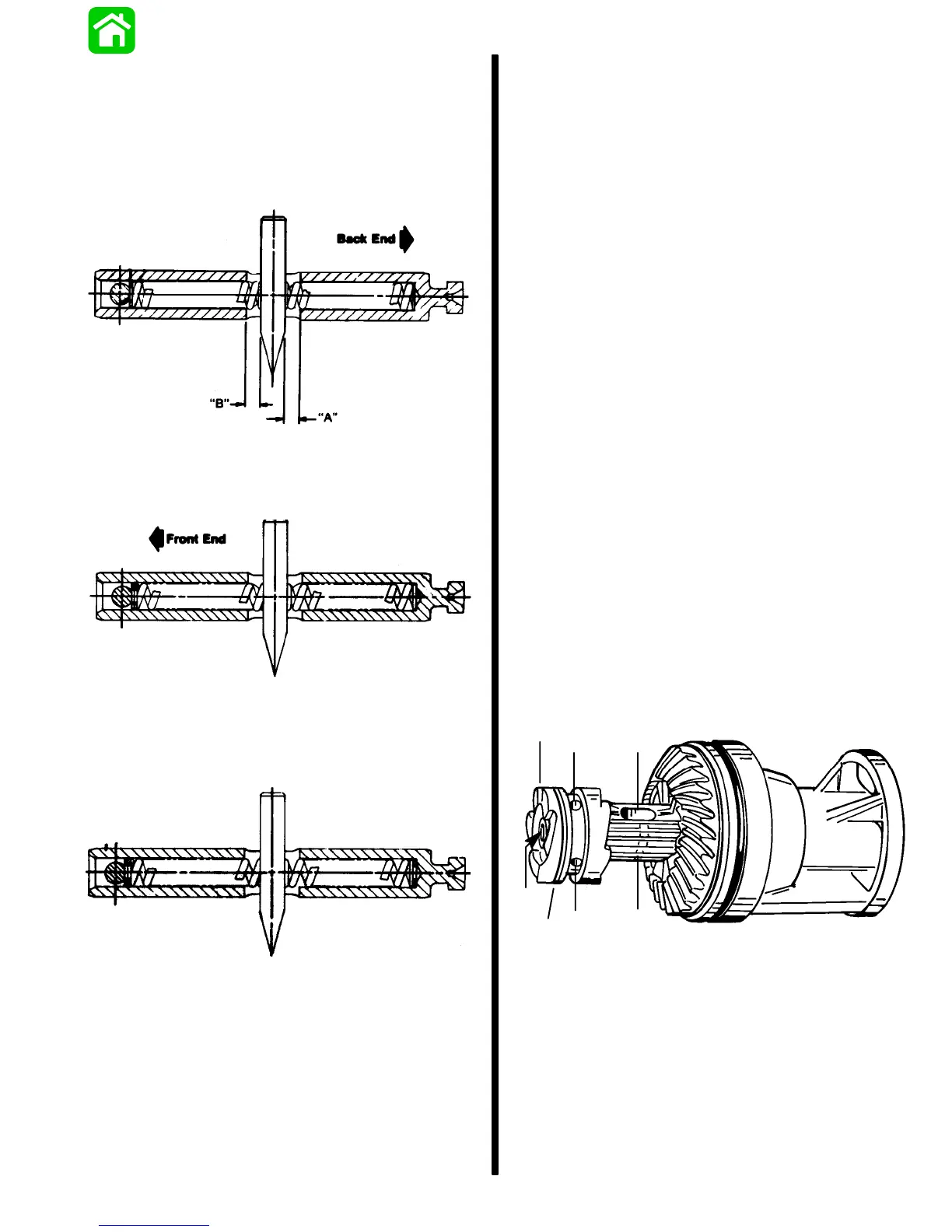

5. Measure distance (A and B) from each end of

elongated slot to the near side of cross pin tool.

The measurements taken must be equal within

1/64″ (0.4mm).

6. If measurements (taken in Step 5) are not equal

to within 1/64″, remove locating pin and re-shim

compression spring.

Clutch Actuator Rod with One Additional Shim

Washer Added to Back End

Clutch Actuator Rod with One Additional Shim

Washer Added to Front End

Clutch Actuator Rod with One Additional Shim

Washer Added to Each End

Shift Shaft Bushing

REASSEMBLY

1. Position shift shaft bushing on a press with

threaded side down.

2. Apply Loctite 271 to outside diameter of oil seal.

3. Press oil seal into shift shaft bushing with lip of

seal up.

4. Wipe any excess Loctite from oil seal and

bushing.

5. Place rubber washer against oil seal.

6. Install O-ring over threads and up against

shoulder of bushing.

7. Lubricate O-ring and oil seal with Quicksilver

2-4-C w/Teflon Marine Lubricant.

Propeller Shaft

REASSEMBLY/INSTALLATION

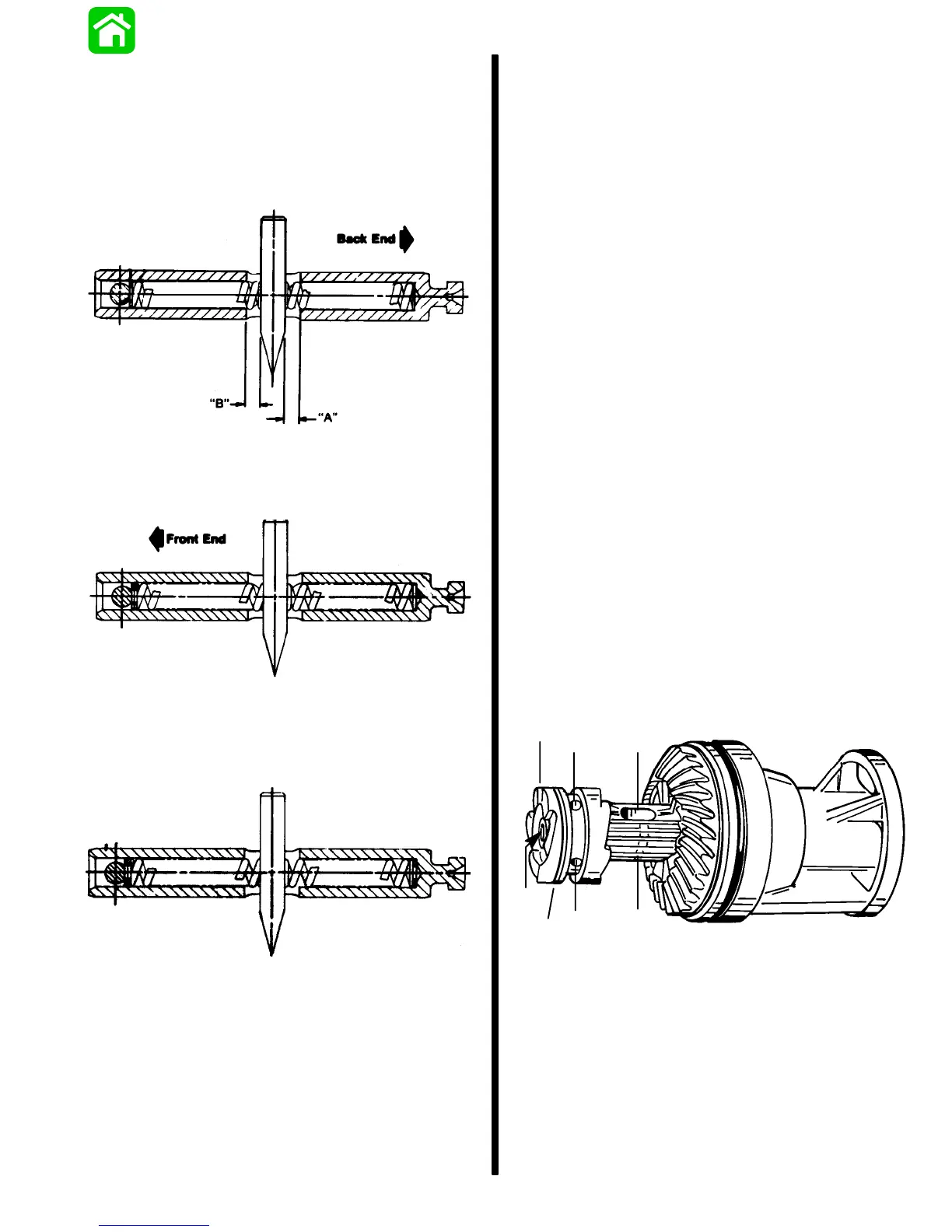

1. Position sliding clutch onto propeller shaft. The

“GROOVED RINGS” on the Sport Master gear

cases should be installed with the grooves

toward the front of the gear housing. On all other

gear cases, the grooves are for manufacturing

purposes only and may be positioned towards

either gear. Cross pin hole and detent holes in

sliding clutch must line up with cross pin slot and

detent notches in propeller shaft.

d

a

g

e

c

b

51913

f

a - Sliding Clutch

b - Propeller Shaft

c - Grooved Rings (Toward Front of Gear Case for Hi-Perfor-

mance Applications)

d - Cross Pin Hole

e - Detent Holes

f - Cross Pin Slot

g - Detent Notches

Loading...

Loading...