6B-30 - LOWER UNIT 90-824052R3 JUNE 2002

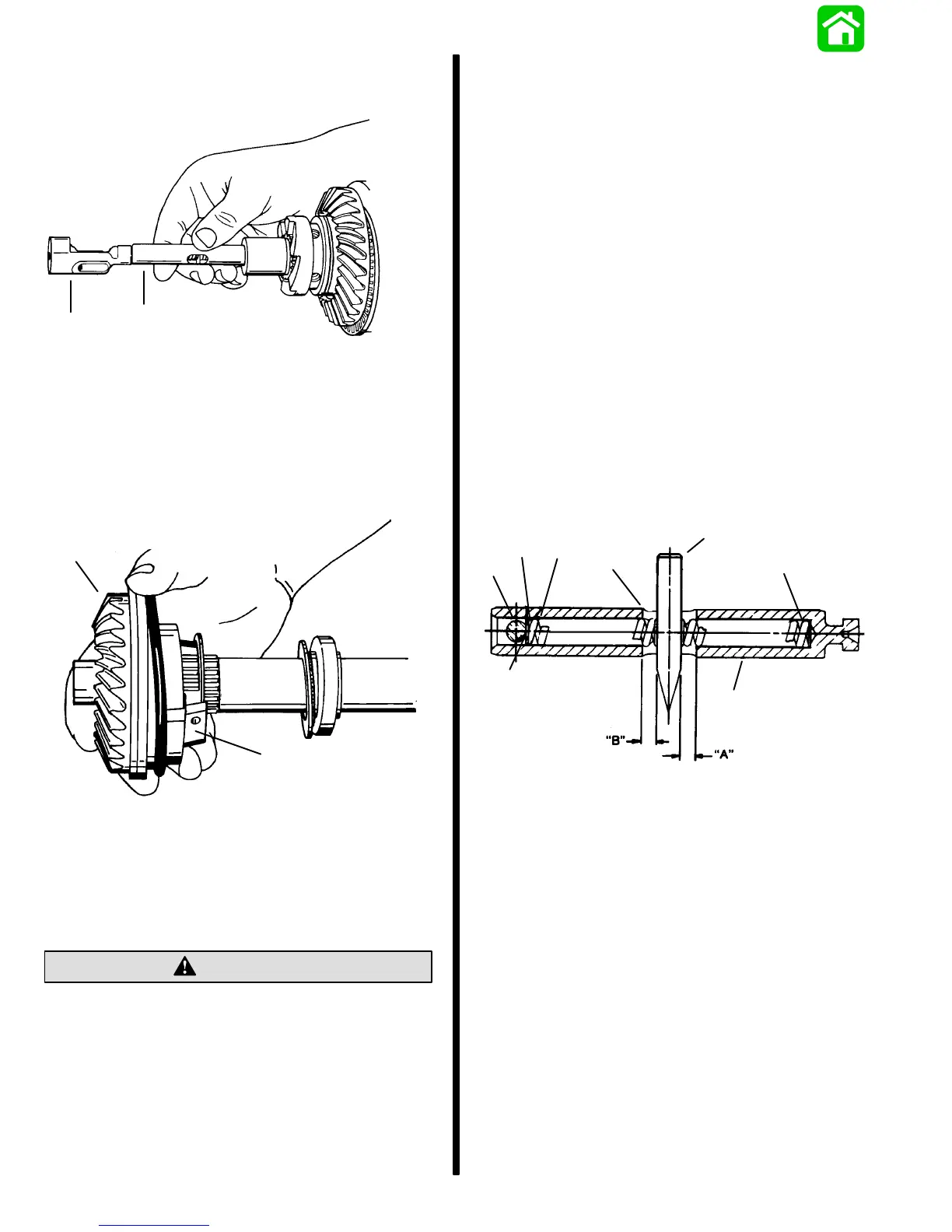

9. Once cam follower and clutch actuator rod are

removed from propeller shaft, lift rod out of cam

follower.

51884

b

a

a - Cam Follower

b - Clutch Actuator Rod

10. Check condition of cam follower. If it shows wear

(pitting, scoring or rough surface), replace cam

follower and shift cam.

11. Remove forward gear and bearing adaptor

assembly.

51913

a

b

a - Forward Gear

b - Bearing Adaptor Assembly

Clutch Actuator Rod

CLEANING AND INSPECTION

CAUTION

Care MUST BE taken when handling clutch

actuator rod. The locating pin is free and will fall

out, allowing compression springs and shims to

fall out.

1. Clean clutch actuator rod in solvent and dry with

compressed air.

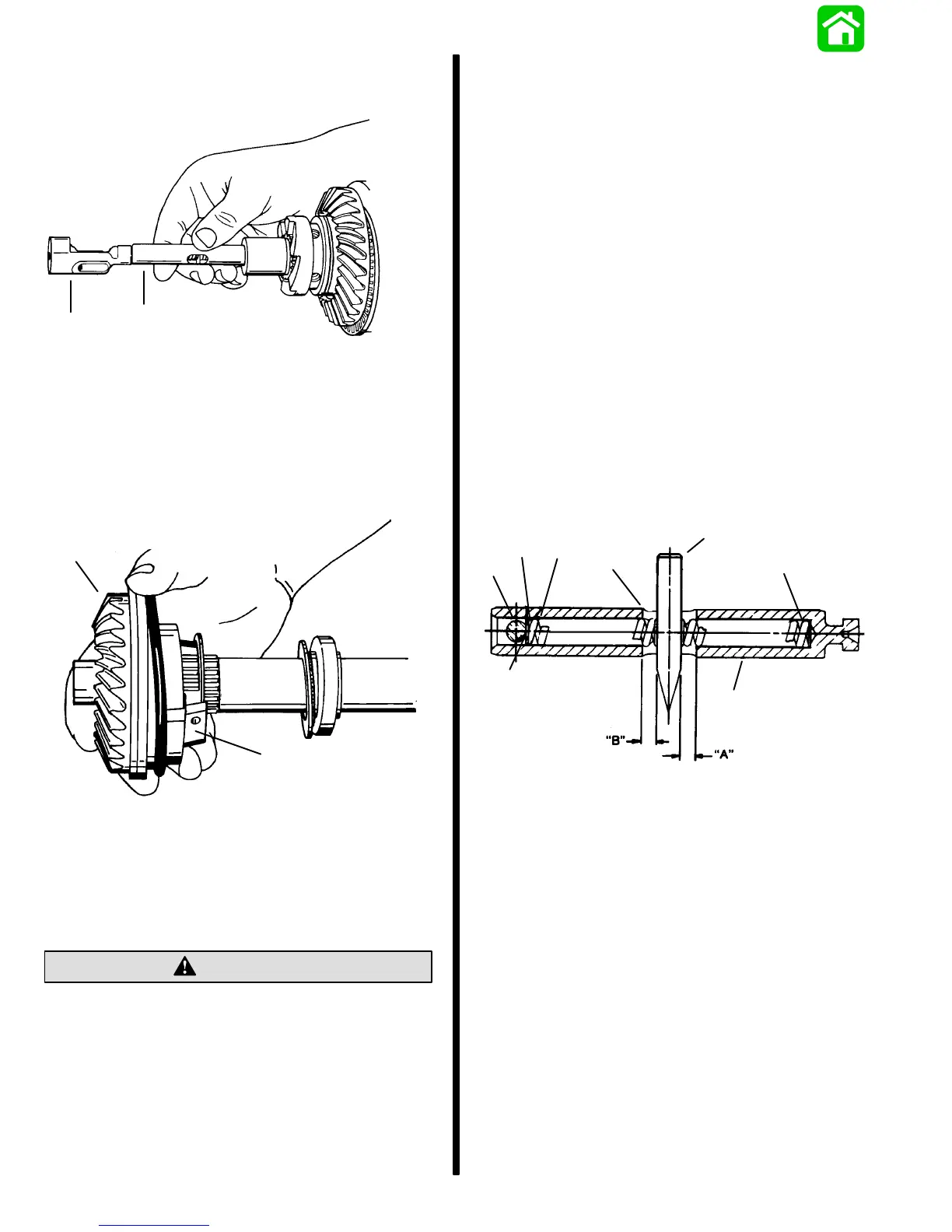

2. Insert Cross Pin Tool (91-86642) between com-

pression springs in elongated slot in clutch rod.

3. Compress both springs by forcing cross pin tool

back-and-forth in elongated slot. This will release

any initial set from springs.

4. Measure distance from each end of elongated

slot to the near side of cross pin tool. The mea-

surement taken must be equal within 1/64″[.016″

(0.4mm)].

5. If measurements (taken in Step 4) are not equal

to within 1/64″, disassembly of clutch actuator

rod must be performed to determine the reason.

[Reasons for unequal measurements may be a

broken spring, a spring of reduced length (see

Step 6) or the wrong spring shimming.]

6. If disassembly is performed on clutch actuator

rod, spring length must be 1.535″ to 1.560″

[1-17/32″ to 1-9/16″ (38.9mm to 39.7mm)].

a

bc

d

e

c

f

g

a - Spring Locating Pin

b - Shim Washer

c - Compression Spring

d - Elongated Slot

e - Cross Pin Tool (91-86642)

f - Clutch Actuator Rod

g - Shim Washer Must Lie Flat on Spring Locating Pin

NOTE: “A” and “B” Measurements Must Be Equal

within 1/64

″

[.016

″

(0.4mm)].

DISASSEMBLY

IMPORTANT: Keep a record of shim amounts and

location during disassembly of clutch actuator

rod to aid in reassembly.

1. Push locating pin out of clutch actuator rod.

Loading...

Loading...