3D-26 - FUEL SYSTEMS 90-824052R3 JUNE 2002

EFI System Test Procedures

Fuel Gauge Connection/Pressure

Test

IMPORTANT: When checking fuel pressure while

engine is running, fuel pressure may fluctuate.

Fuel pressure fluctuation (i.e. 34 to 36 psi “234 to

248 kPa”) is common, as the regulated pressure

is a differential between fuel rail and manifold

vacuum.

Purpose: Checking fuel manifold pressure ensures

that fuel under usable pressure is available to

the fuel injectors. This test isolates the prob-

able cause as either a fuel delivery or EFI

electrical system failure.

IMPORTANT: Fuel pressure should be monitored

through full RPM range to determine fuel supply

problems at high engine speeds.

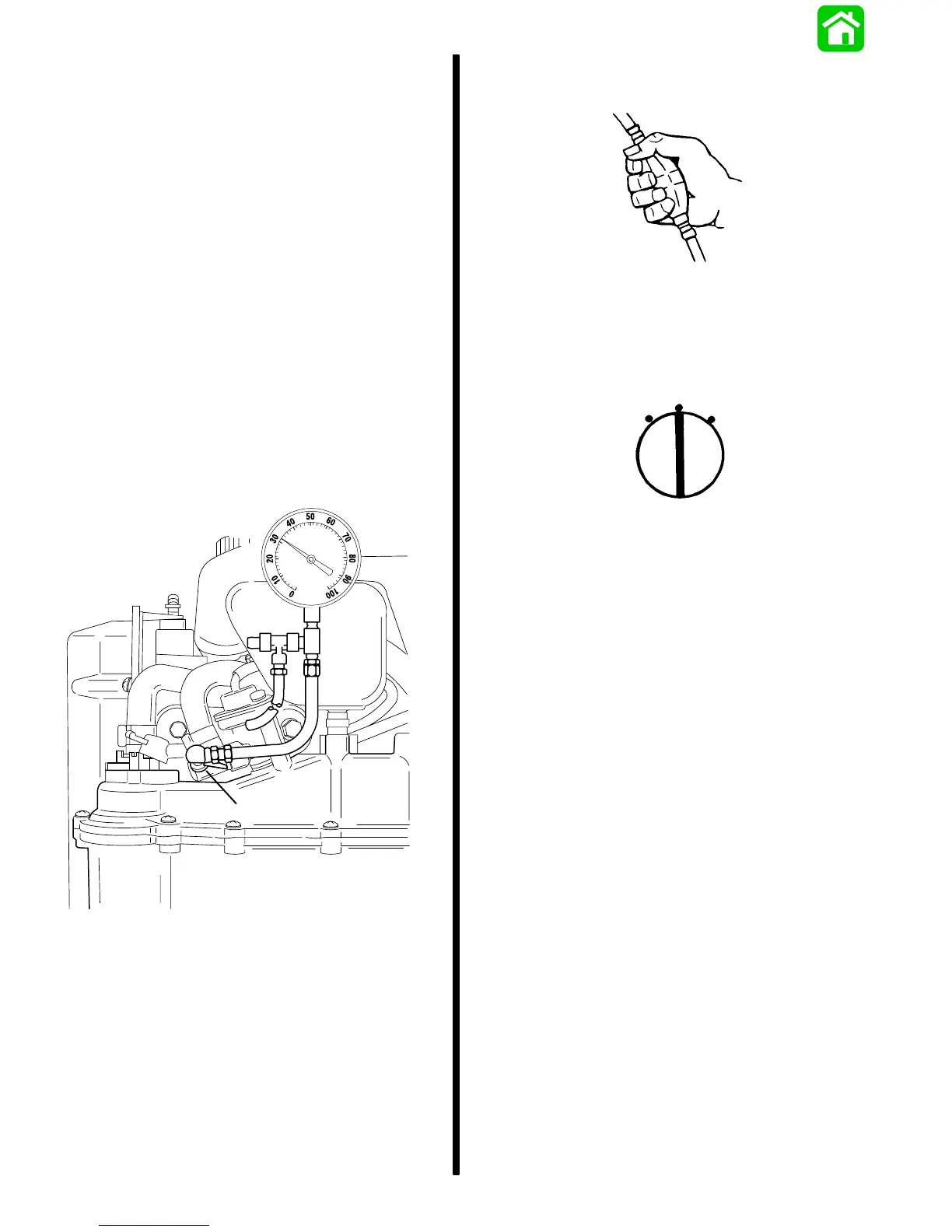

1. Connect fuel pressure gauge to induction

manifold pressure port.

55180

a

a - Pressure Port

2. Prime engine using fuel primer bulb.

3. Turn ignition key switch to “On” position.

OFF

ON

START

4. Operate electric fuel pump for approximately 10

seconds.

NOTE: Fuel pump will only operate for approximately

30 seconds. By turning the key switch to “OFF” and

then back to “ON” the pump will operate for 30

seconds more.

5. Take reading on fuel pressure gauge.

Results: If pressure reading is 34 to 36 psi (234 to

248 kPa), the electric fuel pump is providing

fuel with enough pressure to be used by the

injectors. Pump malfunction is not the cause

of EFI trouble.

If fuel pressure is well below 34 psi (234 kPa), fuel

delivery to electric fuel pump, fuel pump failure or

other related problem exists. Follow low/high fuel

pressure flow charts.

If fuel pressure is above 36 psi (248 kPa) go to fuel

pressure regulator test.

Loading...

Loading...