6C-20 - LOWER UNIT 90-824052R3 JUNE 2002

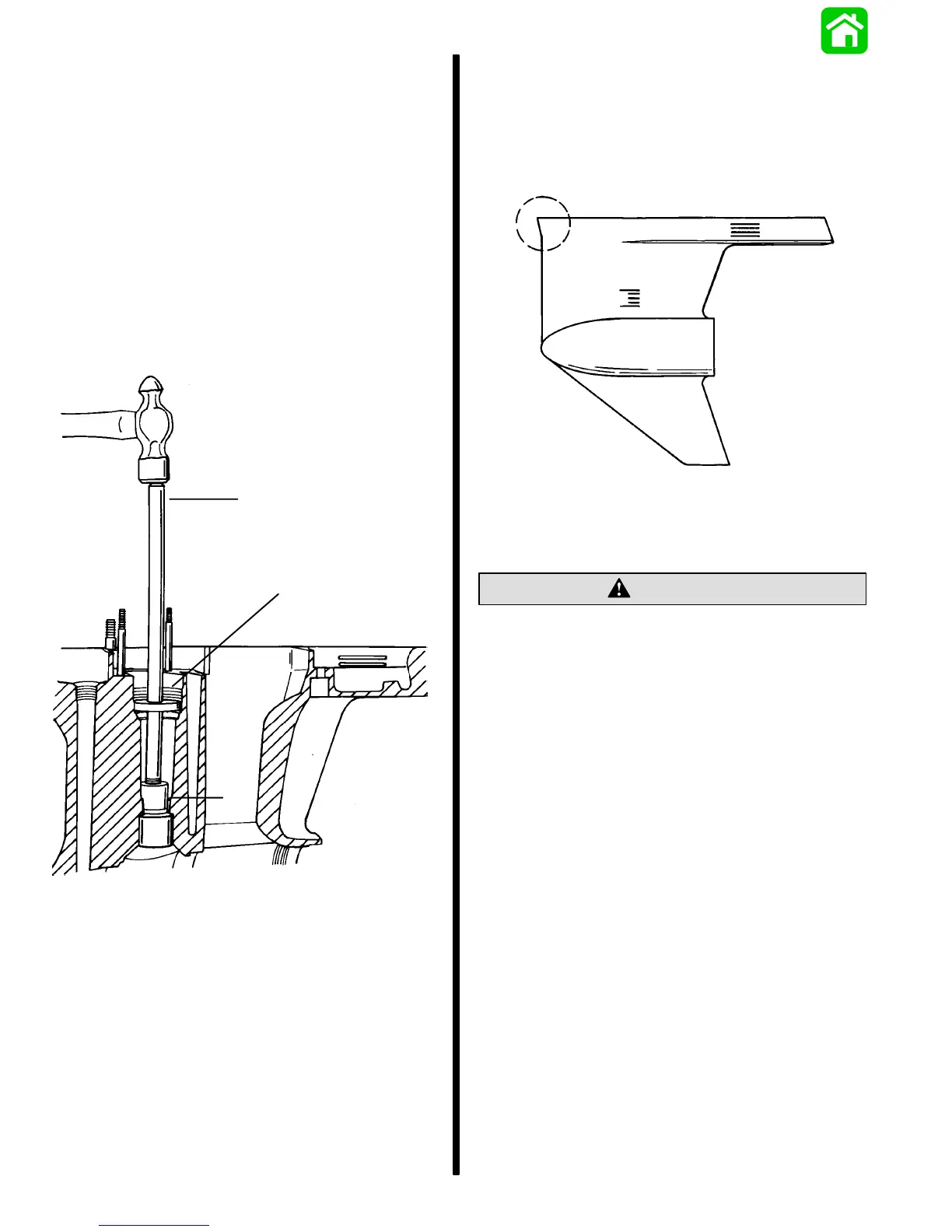

REMOVAL OF DRIVESHAFT NEEDLE BEARING

- LATE MODEL

1. If inspection of driveshaft needle bearing surface

(refer to “CLEANING and INSPECTION,”

following) determines that replacement of needle

bearing is required, remove bearing from gear

housing, following.

2. Remove forward gear from gear housing.

3. Verify 18 loose needle bearings are in place in

bearing race to provide a surface for mandrel to

drive against.

4. Using MANDREL (91-37263), PILOT

(91-36571), and DRIVER ROD (91-37323),

remove race from gear housing.

b

a

51869

c

a - Mandrel (91-37263)

b - Pilot* (91-36571)

c - Driver Rod* (91-37323)

*From Bearing Removal and Installation Kit (91-31229A5)

IMPORTANT: Discard driveshaft needle bearing

after removal (bearing cannot be reused).

IMPORTANT: If DRIVESHAFT NEEDLE BEARING

RACE has spun in bore in gear housing, gear

housing MUST BE REPLACED as reinstalling

new bearing in old housing will result in repeat

bearing failure.

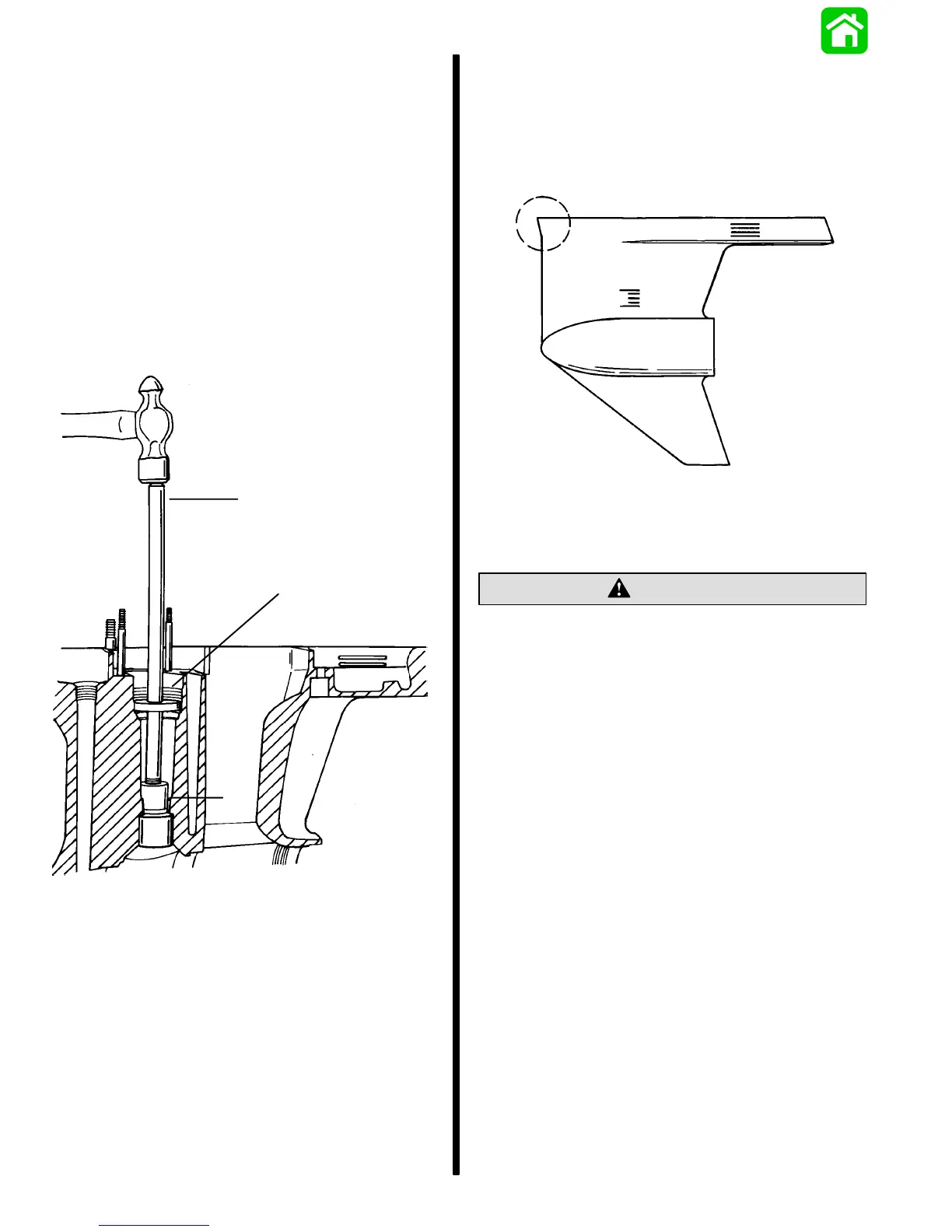

Reassembly and Installation

Driveshaft Needle Bearing

INSTALLATION - EARLY MODEL

50737

EARLY MODEL

NOTE: New gear housings have a driveshaft needle

bearing already installed.

CAUTION

If driveshaft needle bearing failure has occurred,

and original bearing race has turned in the gear

housing, gear housing must be replaced. Loose

fitting needle bearing will move out of position

and cause repeated failure.

1. Position driveshaft needle bearing over driver

head (from Bearing Removal and Installation Kit

91-31229A1) with numbered side of bearing

toward shoulder of driver head.

2. Thread driver rod from kit into driver head.

3. Lubricate needle bearing area of driveshaft

cavity with a thin coat of Quicksilver 2-4-C

w/Teflon Marine Lubricant.

4. Position rod, driver head and bearing into gear

housing driveshaft cavity.

5. Place pilot washer (from kit) over driver rod and

slide it down into driveshaft bearing cavity.

Loading...

Loading...