90-824052R3 JUNE 2002 FUEL SYSTEMS - 3C-23

Vapor Separator Fuel Delivery Test

Purpose: Verifying there is adequate fuel flow to the

electric fuel pump (through full RPM range)

will determine components in low pressure

fuel system are functioning correctly.

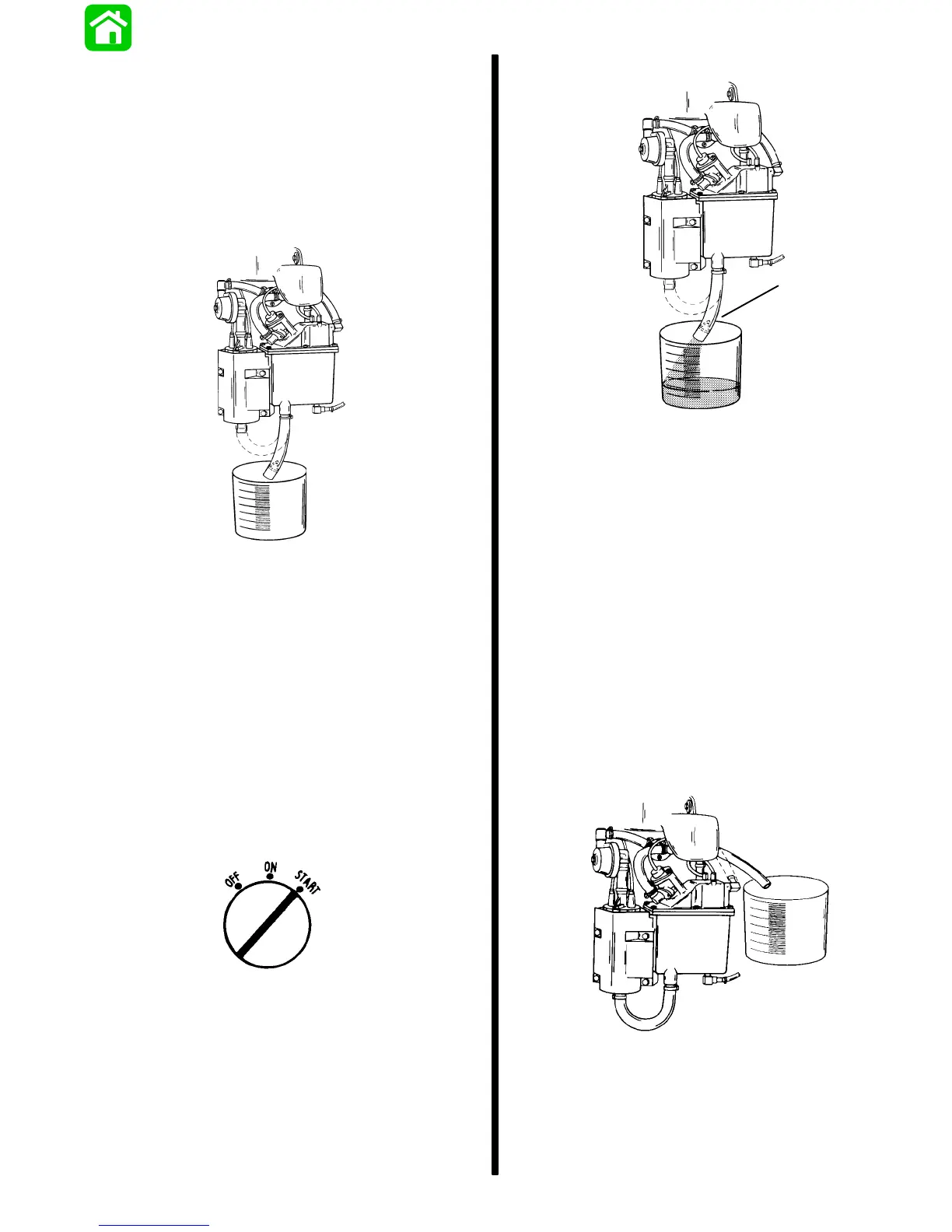

Procedure: STEP 1: Remove hose from intake

port of electric fuel pump and put discon-

nected end of hose in clean container.

51798

Results: If fuel flow is present, fuel is being delivered

to electric fuel pump. Go to high pressure flow

chart.

If fuel flow is not present, proceed to step 2.

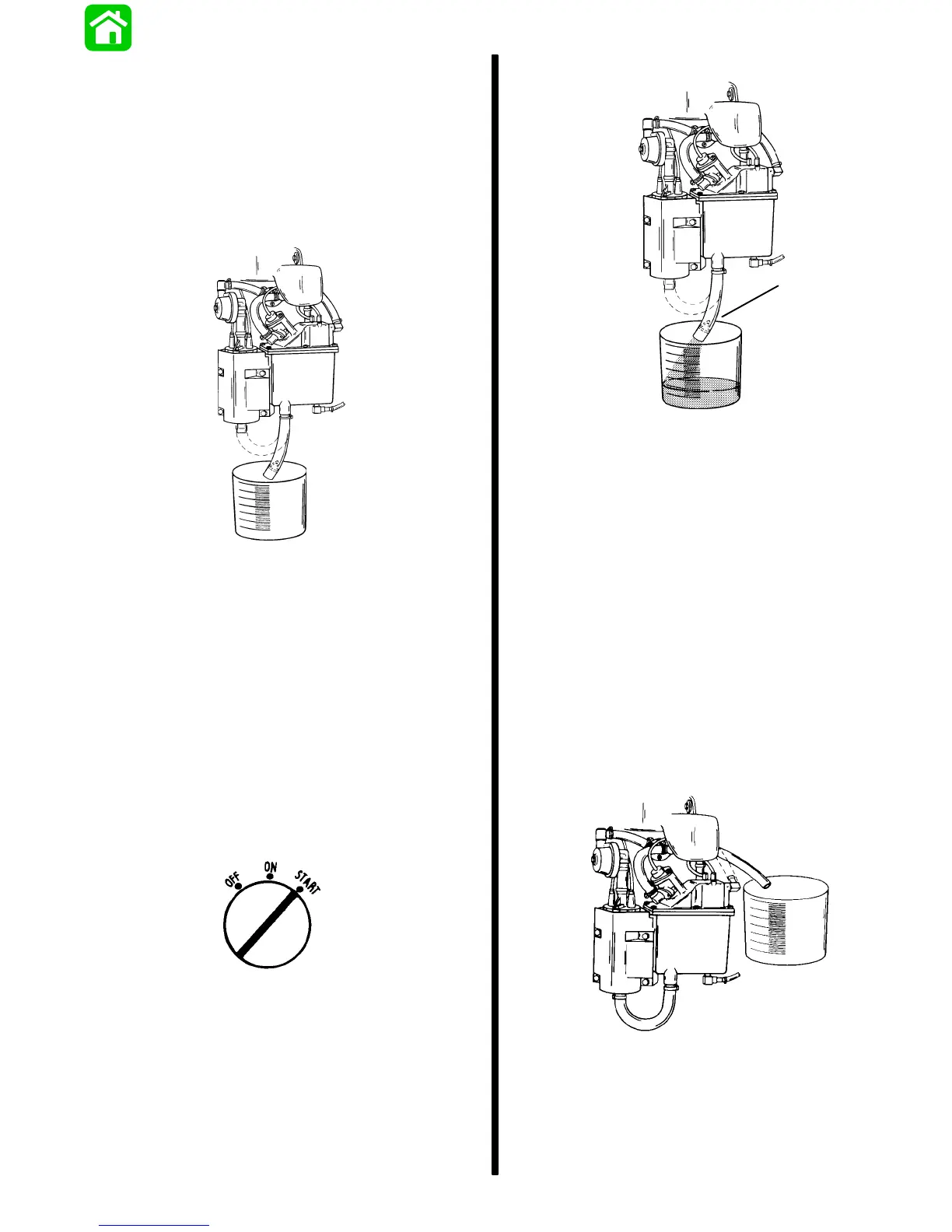

STEP 2: Place emergency stop switch in OFF

position to prevent engine from starting. If

boat is not equipped with a emergency

stop switch, connect a jumper lead from

the BLACK/YELLOW terminal on the

switch box to engine ground.

STEP 3: Turn ignition key switch to “START” and

operate starter motor for 10 to 20

seconds.

STEP 4: Look for fuel flow from hose.

IN-LINE

FILTER

51798

Results: If low or no fuel flow is present following

inspection of in-line filter, perform Vapor

Separator Float Test.

Vapor Separator Float Test

Purpose: This test will indicate if float is stuck in the

up position.

NOTE: If float is stuck down vapor separator will over

flow causing a rich condition.

Procedure: If float is suspected of sticking in the up

position:

STEP 1: Remove fuel inlet hose from vapor

separator and put end of hose in clean

container.

STEP 2: Remove all spark plugs from engine to

prevent engine from starting.

Loading...

Loading...