3E-10 - FUEL SYSTEMS 90-824052R3 JUNE 2002

Installing Drive Gear (for Oil Injection

Pump) Onto Crankshaft

IMPORTANT: Oil pump drive gear retaining

screws ARE STAKED after installation. DO NOT

remove drive gear from crankshaft unless gear is

damaged or shows signs of excessive wear.

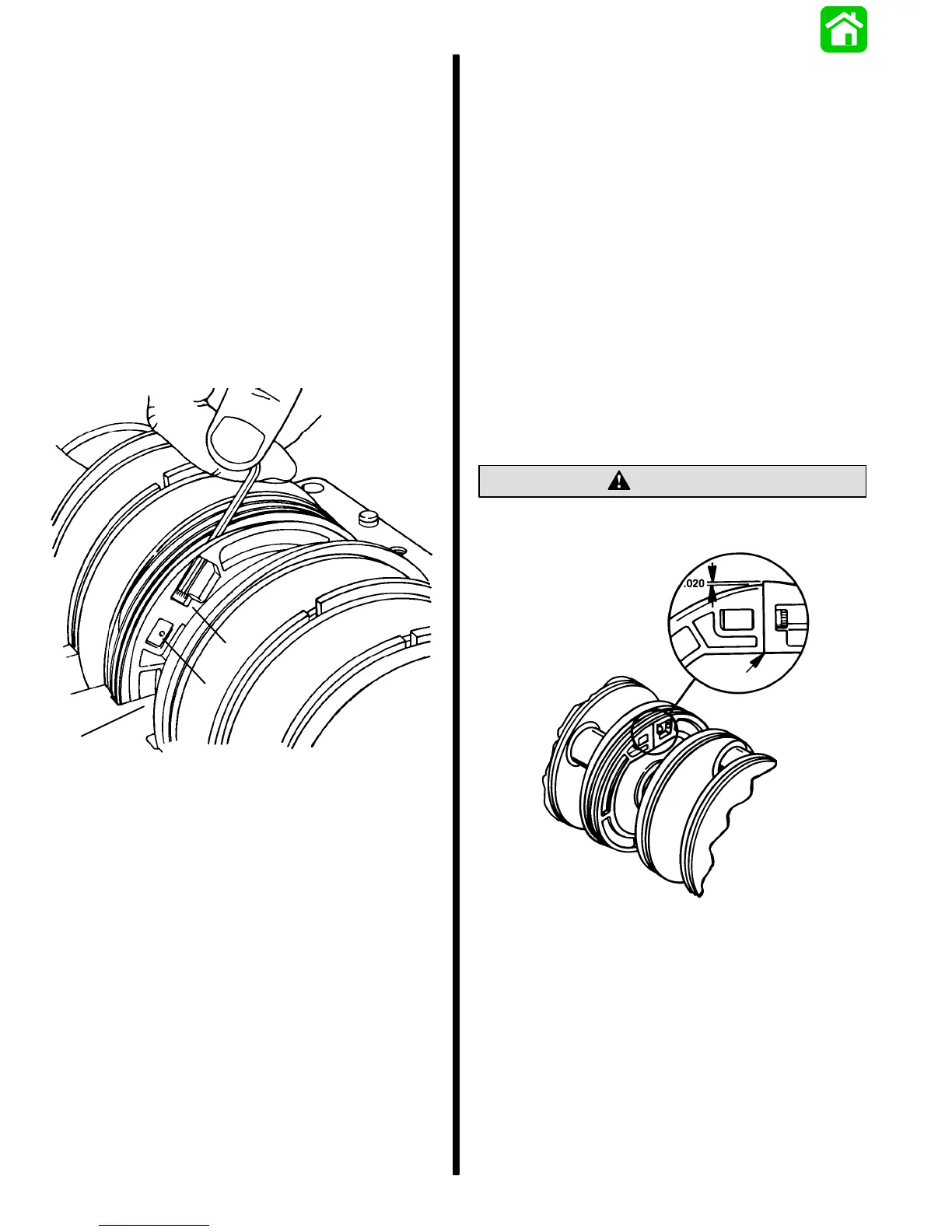

REMOVAL OF DRIVE GEAR

1. Rotate crankshaft to gain access to two drive

gear retaining allen screws.

2. Remove two screws and remove drive gear from

crankshaft. DO NOT reuse retaining screws as

screw threads may be damaged by factory stak-

ing process.

b

a

c

51892

a - Retaining Nut

b - Allen Screw

c - Center Main Bearing (Hidden)

INSTALLATION OF NEW DRIVE GEAR

NOTE: If drive gear must be replaced, it is recom-

mended that the oil pump be inspected for operating

smoothness; plastic bearing, bronze bushing and oil

pump drive shaft be inspected for wear, gauling or

damage. Replace parts as required.

1. Align drive gear halves on crankshaft with retain-

ing screw access holes towards center main

bearing.

2. Clean retaining screw threads with Loctite Primer

T (92-59327-1). Apply Loctite 680 (obtain locally)

to screw threads.

3. Secure drive gear halves together with retaining

nuts and allen screws. Torque screws to 8 Ib. in.

(1.0 N·m).

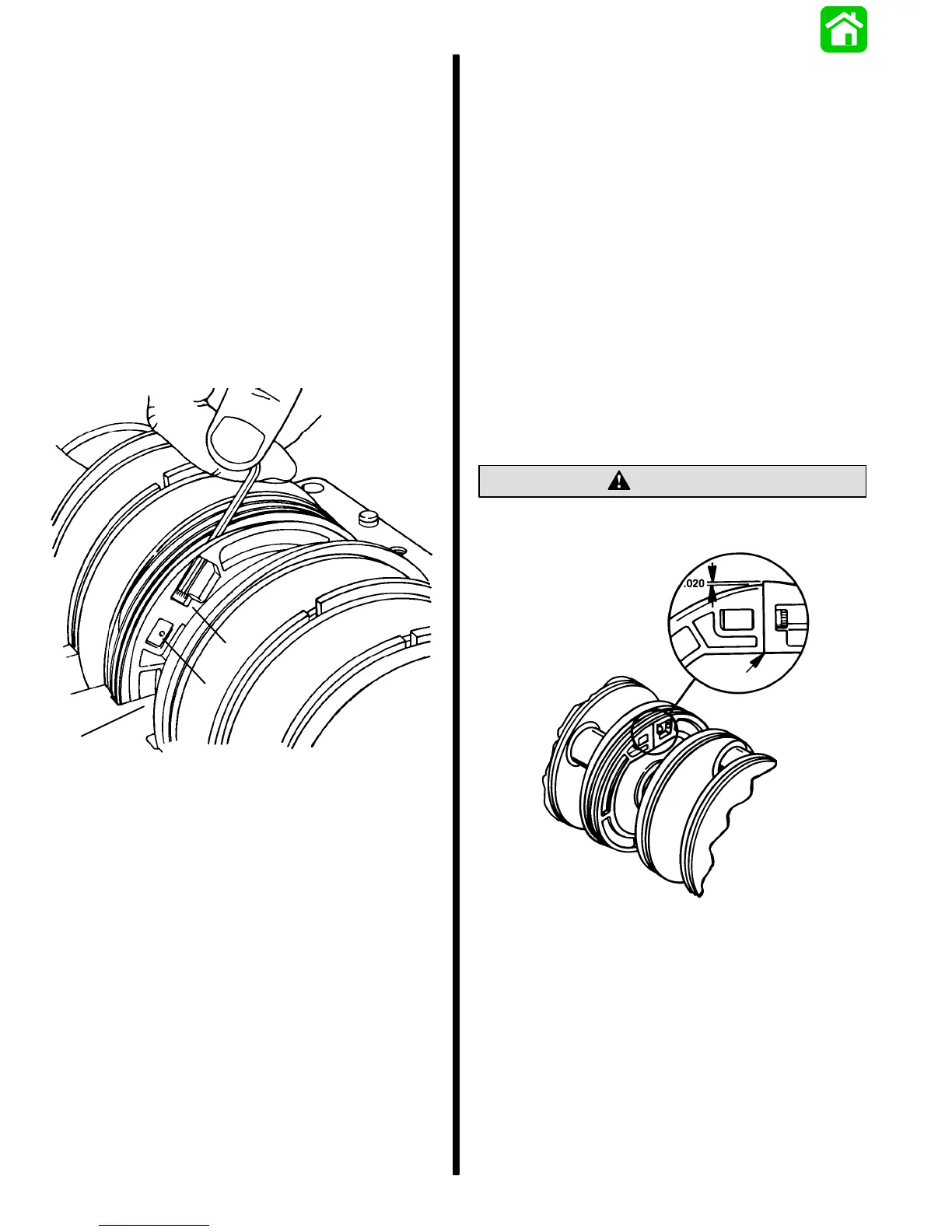

4. Check gear halve split lines. Split should be

drawn tight together (zero clearance) if gear

halves are properly installed.

CAUTION

Gear tooth mismatch at split line must not exceed

0.020 in. (0.50mm) or gear failure will result.

50755

Motion Sensor

Testing Procedure--Refer to “Oil Injection System

Trouble Shooting Chart,” following:

Removal--Remove screw securing sensor to oil

pump. Disconnect WHITE and BLUE/WHITE leads

from WARNING MODULE. Remove BLACK LEAD

from engine ground. Remove MOTION SENSOR

from powerhead.

Loading...

Loading...