ELECTRICAL - 2B-15

90-824052R3 JUNE 2002

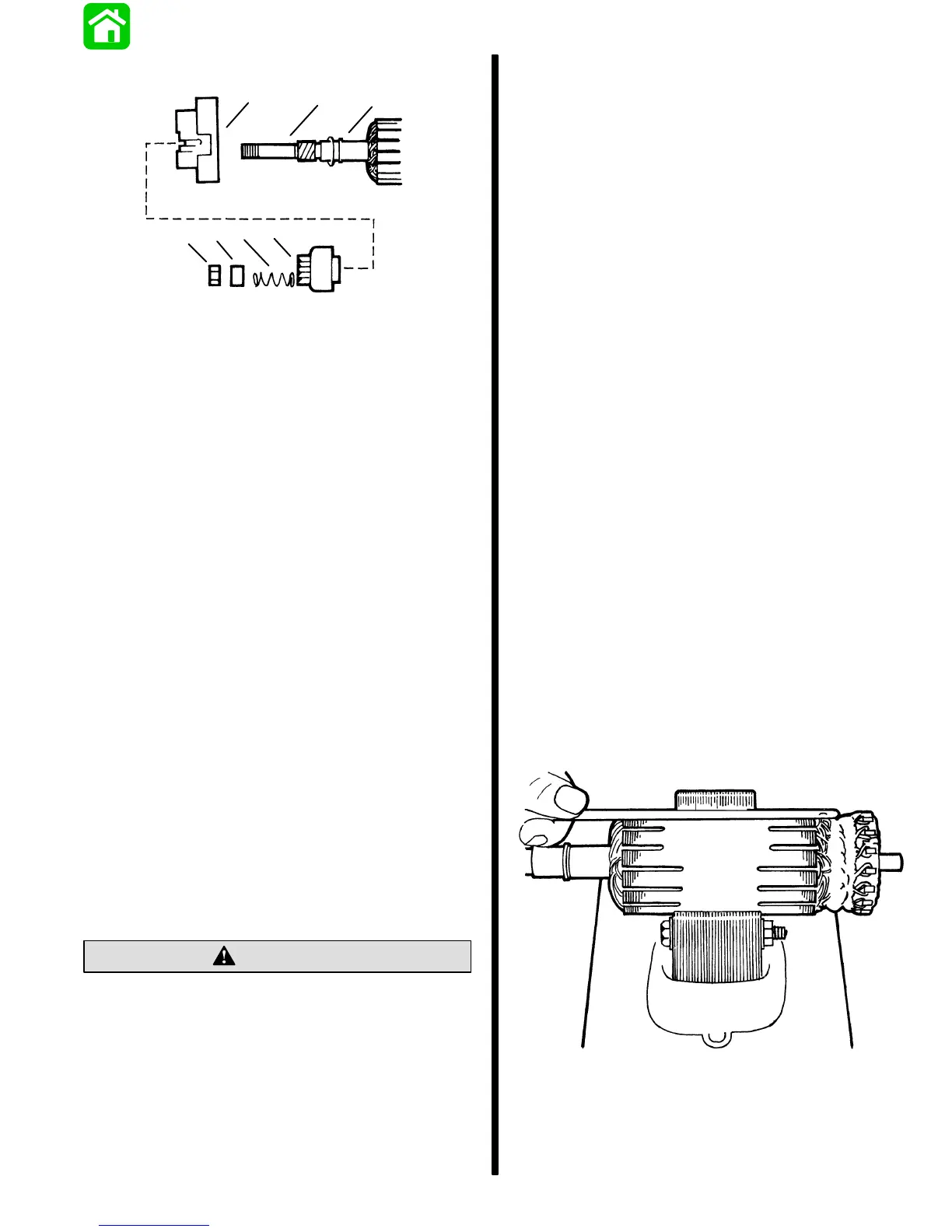

Then remove parts from shaft.

11658

e

f

g

a

b

c

d

a - Locknut

b - Spacer

c - Spring

d - Drive Assembly

e - Drive End Cap

f - Armature Shaft

g - Washer

Starter Cleaning, Inspection and

Testing

CLEANING AND INSPECTION

1. Clean all starter motor parts.

2. Check pinion teeth for chips, cracks or excessive

wear.

3. Replace the drive clutch spring and/or collar if

tension is not adequate or if wear is excessive.

4. Inspect brush holder for damage or for failure to

hold brushes against commutator.

5. Replace brushes that are pitted or worn to less

than 1/4 in. (6.4mm) in length.

6. Inspect the armature conductor (commutator bar

junction) for a tight connection. A loose

connection (excessive heat from prolonged

cranking melts solder joints) results in a burned

commutator bar.

7. Resurface and undercut a rough commutator as

follows:

CAUTION

Do not turn down the commutator excessively.

a. Resurface the commutator and undercut the

insulation between the commutator bars

1/32 in. (0.8mm) to the full width of the insu-

lation and so that the undercut is flat.

b. Clean the commutator slots after

undercutting.

c. Sand the commutator lightly with No. 00

sandpaper to remove burrs, then clean the

commutator.

d. Recheck the armature on a growler for shorts

as specified in the following procedure

(“Testing”).

8. Open-circuited armatures often can be repaired.

The most likely place for an open circuit is at the

commutator bars, as a result of long cranking

periods. Long cranking periods overheat the

starter motor so that solder in the connections

melts and is thrown out. The resulting poor

connections then cause arcing and burning of the

commutator bars.

9. Repair bars, that are not excessively burned, by

resoldering the leads in bars (using rosin flux

solder) and turning down the commutator in a

lathe to remove burned material, then undercut

the mica.

10. Clean out the copper or brush dust from slots

between the commutator bars.

11. Check the armature for ground. See the following

procedure (“Testing”).

TESTING

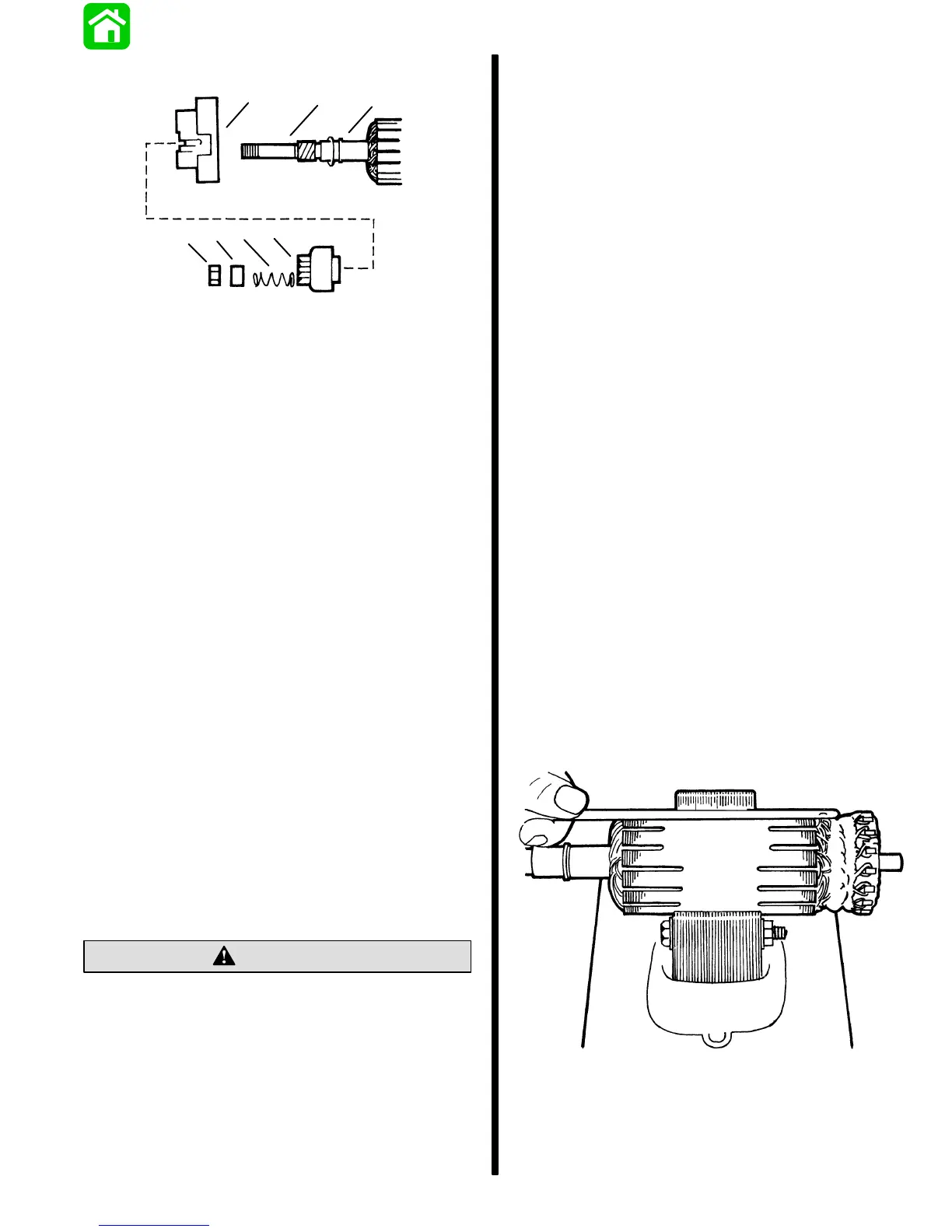

Armature Test for Shorts

Check armature for short circuits by placing on

growler and holding hack saw blade over armature

core while armature is rotated. If saw blade vibrates,

armature is shorted. Recheck after cleaning between

commutator bars. If saw blade still vibrates, replace

armature.

11669

Loading...

Loading...