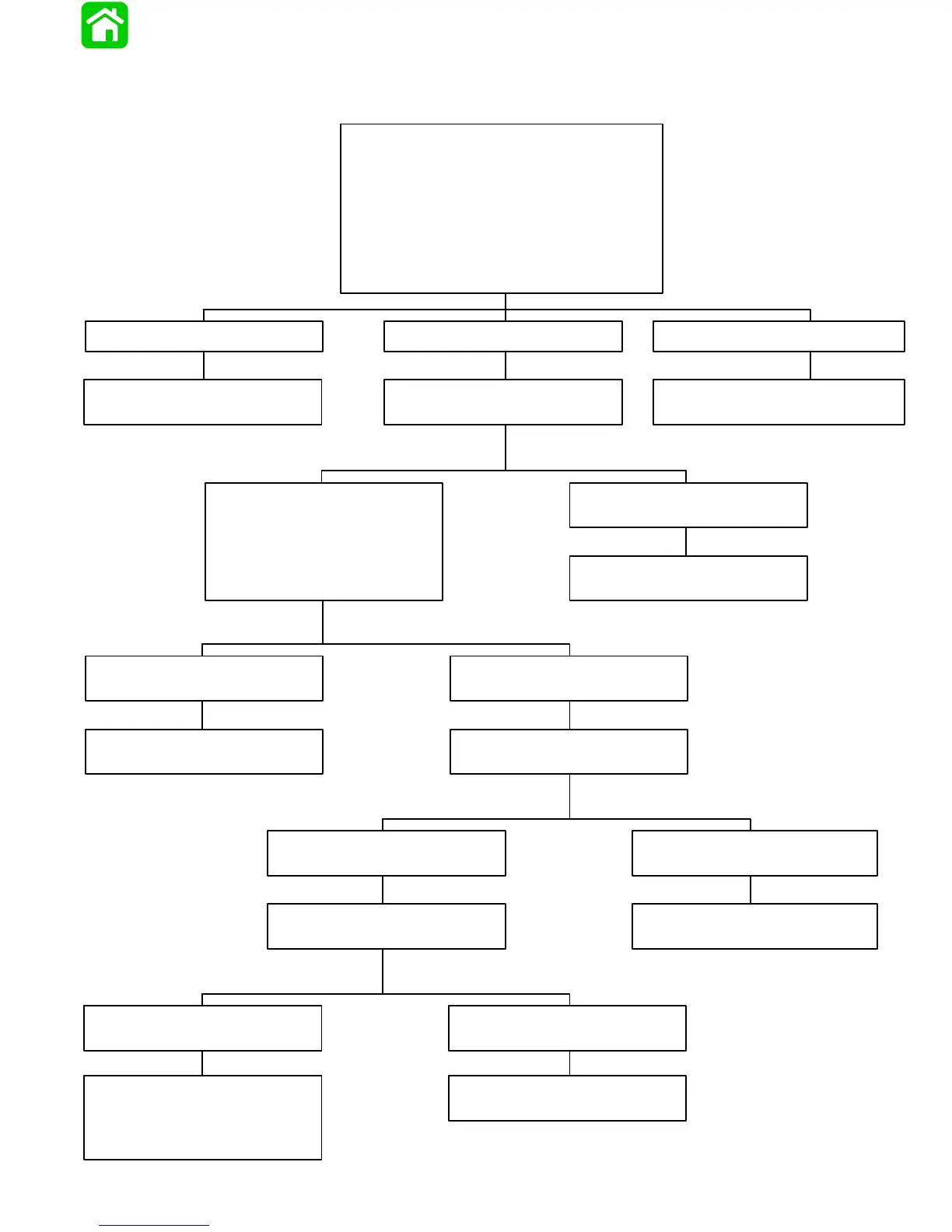

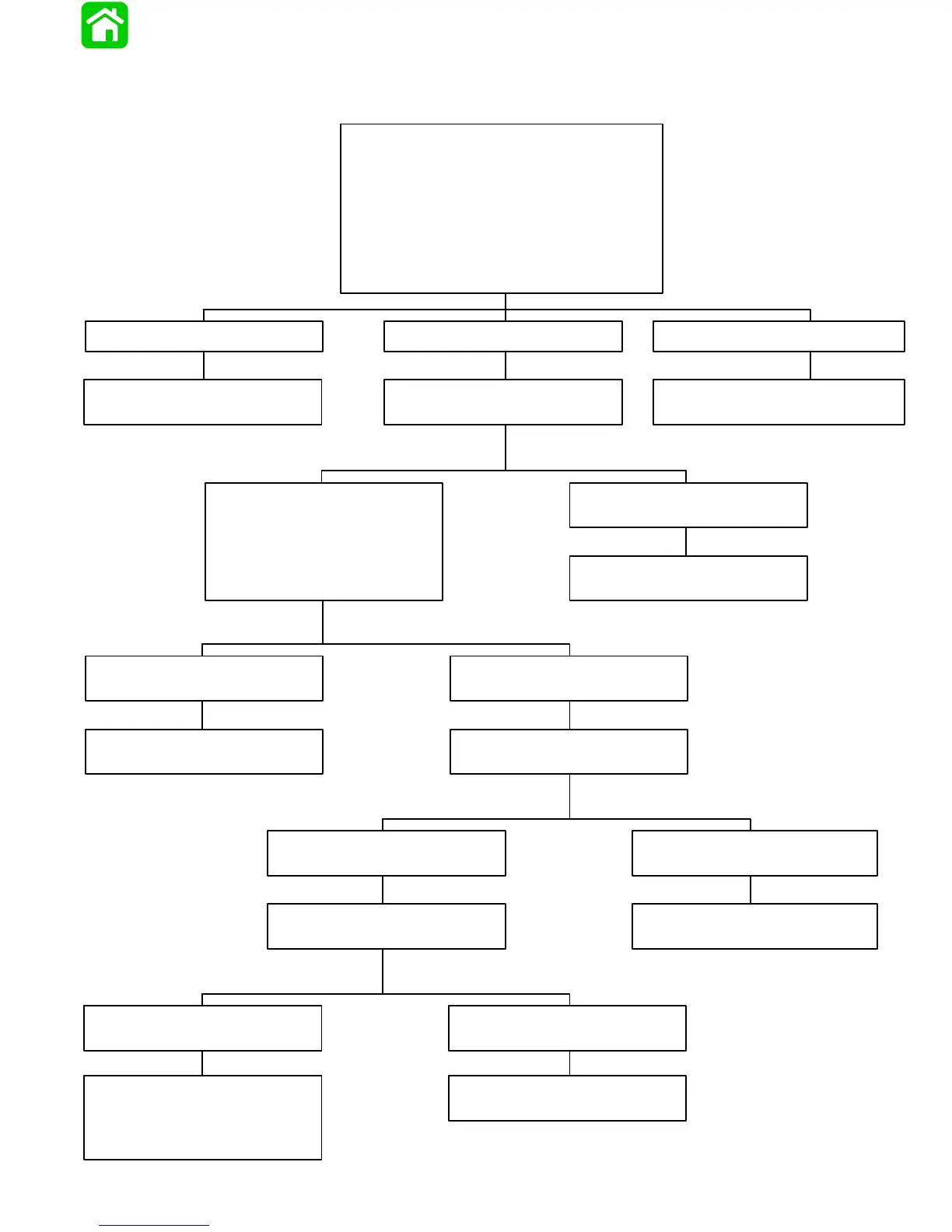

• Perform all preliminary checks 3D-13.

• Install fuel pressure gauge (P/N 91-16850A2)

on to manifold pressure port.

• Place ignition switch in “OFF” position 30 sec-

onds before testing.

• Place ignition switch in “ON” position and note

pressure within 30 seconds (34 to 36 psi; 234 to

248 kPa).

No or low fuel pressurePump does not run Fuel pressure above 36 psi (248 kPa)

Perform Vapor Separator Fuel

Delivery Test (page 3D-27).

Follow High Pressure Fuel

Route Flow Chart.

Follow High Pressure Fuel

Route Flow Chart.

No or little fuel flow from vapor

separator. Reconnect hose.

Fuel flows freely from vapor

separator. Reconnect hose.

Perform Vapor Separator Float

Test (page 3D-28).

Follow High Pressure Fuel

Route Flow Chart.

Fuel flows from fresh fuel inlet

hose.

Little or no flow from fresh fuel

inlet hose. Reconnect hose.

Inspect float system of vapor

separator.

Perform Water Separating Filter

Flow Test (page 3D-28).

Low or no fuel flow from water sep-

arating inlet hose. Reconnect hose.

Fuel flows freely from water separat-

ing filter inlet hose. Reconnect hose.

Perform Pulse Fuel Pump Deliv-

ery Test (page 3D-29).

Replace water separating

filter.

Fuel flows freely from pulse

pump inlet hose.

No fuel flow to pulse fuel

pump.

See pulse pump removal and

inspection section 3A. Locate all

fragments of failed pump before

reassembly.

Check for restrictions, holes or

loose connections from fuel supply.

Results Results

Results

Results

Results

Results

ResultsResults

Check in-line Filter

90-824052R3 JUNE 2002 FUEL SYSTEMS - 3D-23

EFI Fuel Management (Low Pressure Fuel Route)

Loading...

Loading...