4A-30 - POWERHEAD 90-824052R3 JUNE 2002

Reed Block Assembly

IMPORTANT: DO NOT remove reeds from reed

blocks, unless replacement is necessary. DO

NOT turn used reeds over for re-use. Replace

reeds in sets only.

1. Thoroughly clean gasket surfaces of reed blocks

and reed block housing. Check for deep grooves,

cracks and distortion that could cause leakage.

Replace parts as necessary.

2. Check for wear (indentations) on face of each

reed block. Replace block(s), if reeds have made

indentations.

3. Check for chipped and broken reeds.

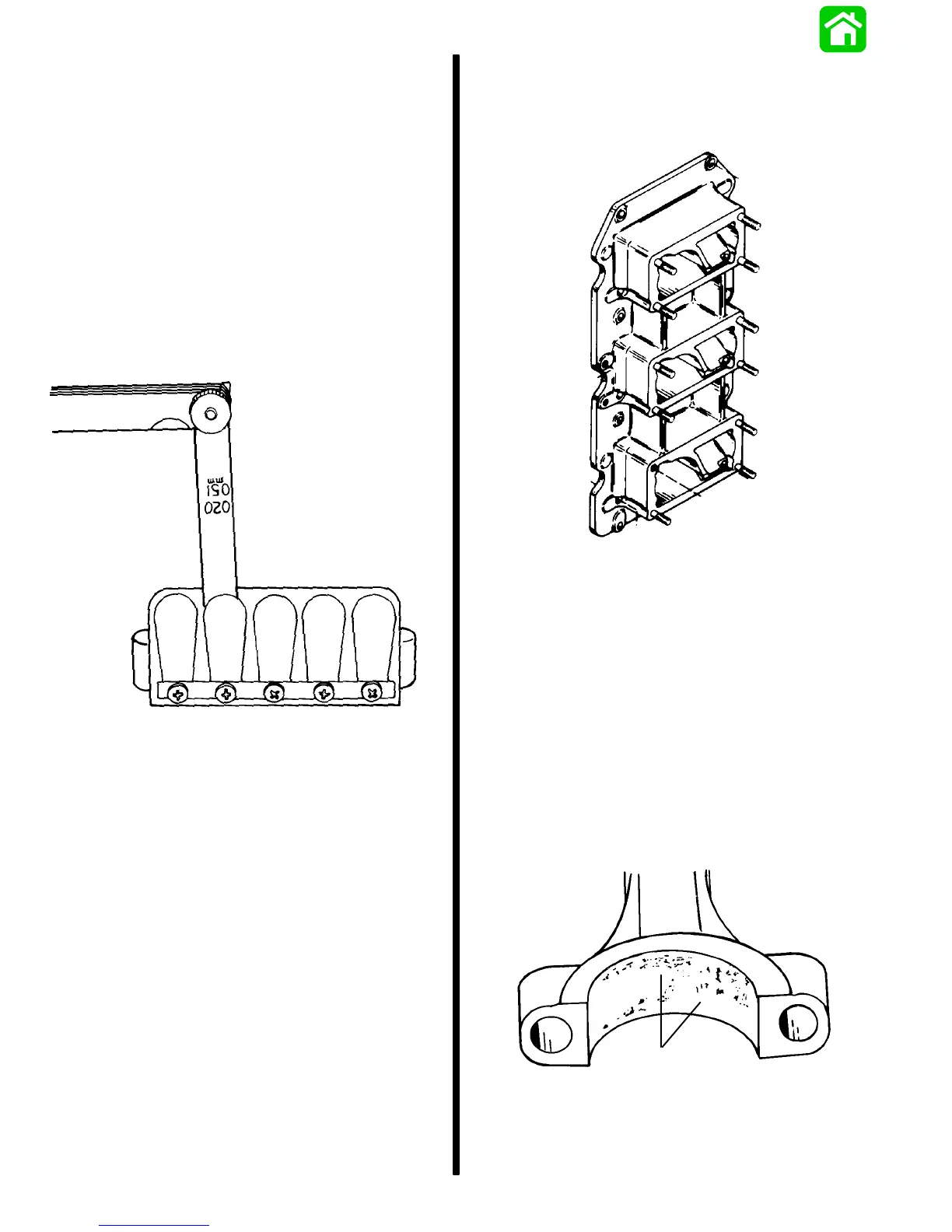

51851

Allowable reed opening is 0.020 in. (0.51mm) or less.

Replace reeds if either reed is standing open more

than 0.020 in. (0.51mm).

Reed Block Housing

1. Check rubber bleed hoses. Replace any hose

that is cracked, cut or deteriorating.

2. Check operation of bleed system check valves in

reed block housing. If valves are working

properly, air can be drawn thru check valves “one

way” only. If air can pass thru a check valve both

ways, valve is not working properly and must be

replaced.

3. Check that bleed system check valves are

pressed tight into reed housing.

4. Inspect passages in reed block housing to be

sure that they are not obstructed.

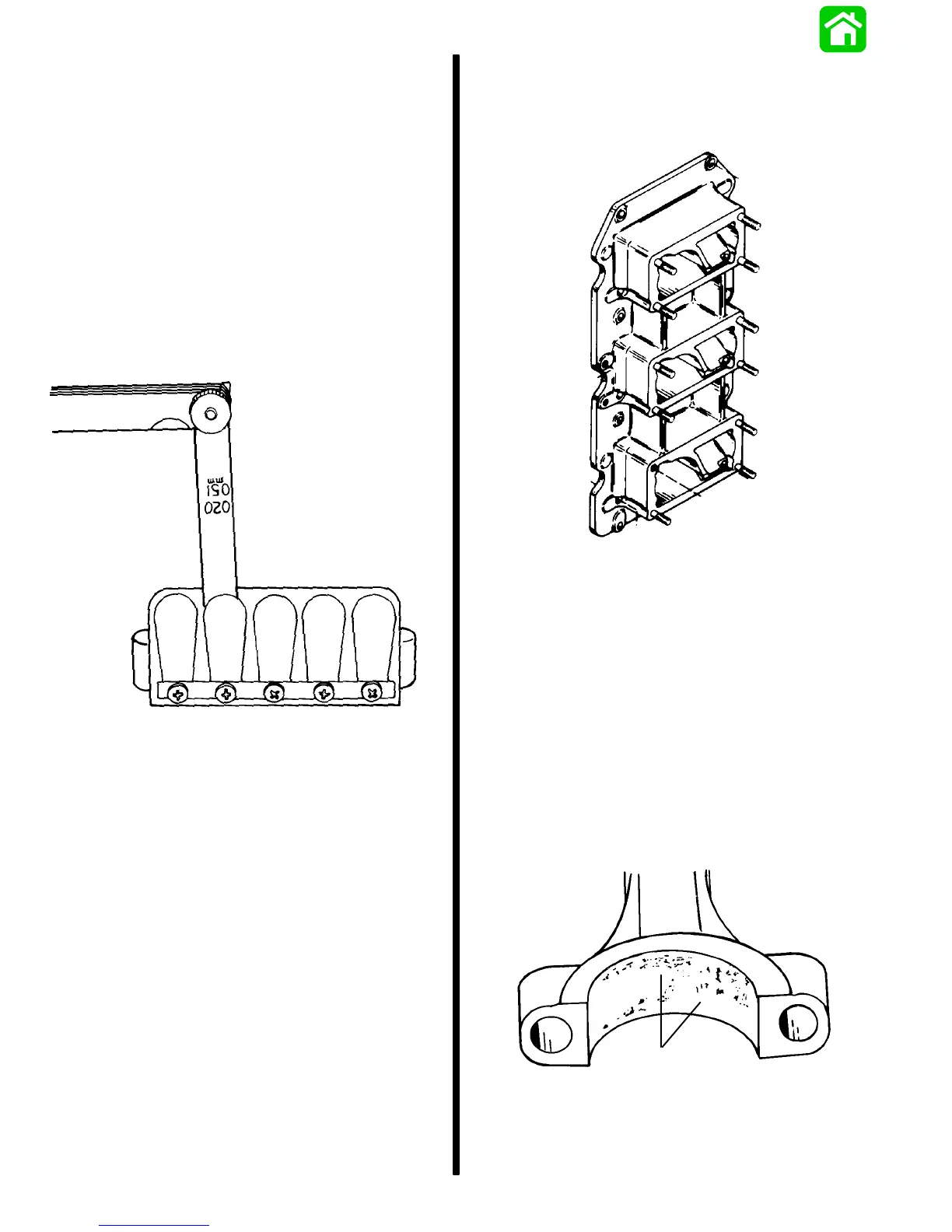

Connecting Rods

1. Check connecting rods for alignment by placing

rods on a surface plate. If light can be seen under

any portion of machined surfaces, if rod has a

slight wobble on plate, or if a 0.002 in. (0.051mm)

feeler gauge can be inserted between any

machined surface and surface plate, rod is bent

and must be discarded.

2. Overheating: Overheating is visible as a bluish

bearing surface color that is caused by inade-

quate lubrication or excessive RPM.

3. Rust: Rust formation on bearing surfaces

causes uneven pitting of surface(s).

a

51853

a - Pitting

Loading...

Loading...