6D-28 - LOWER UNIT 90-824052R3 JUNE 2002

8. Place shim(s) (retained from disassembly) into

gear housing. If shim(s) were lost or are not

reusable (damaged), start with approximately

0.010″ (0.254mm).

9. Install bearing race and bearing retainer.

d

b

a

c

51880

a - Shim(s)

b - Bearing Race

c - Bearing Retainer (Word “OFF” must be visible)

Torque to 100 lb. ft. (135.5 N·m)

d - Bearing Retainer Tool (91-43506)

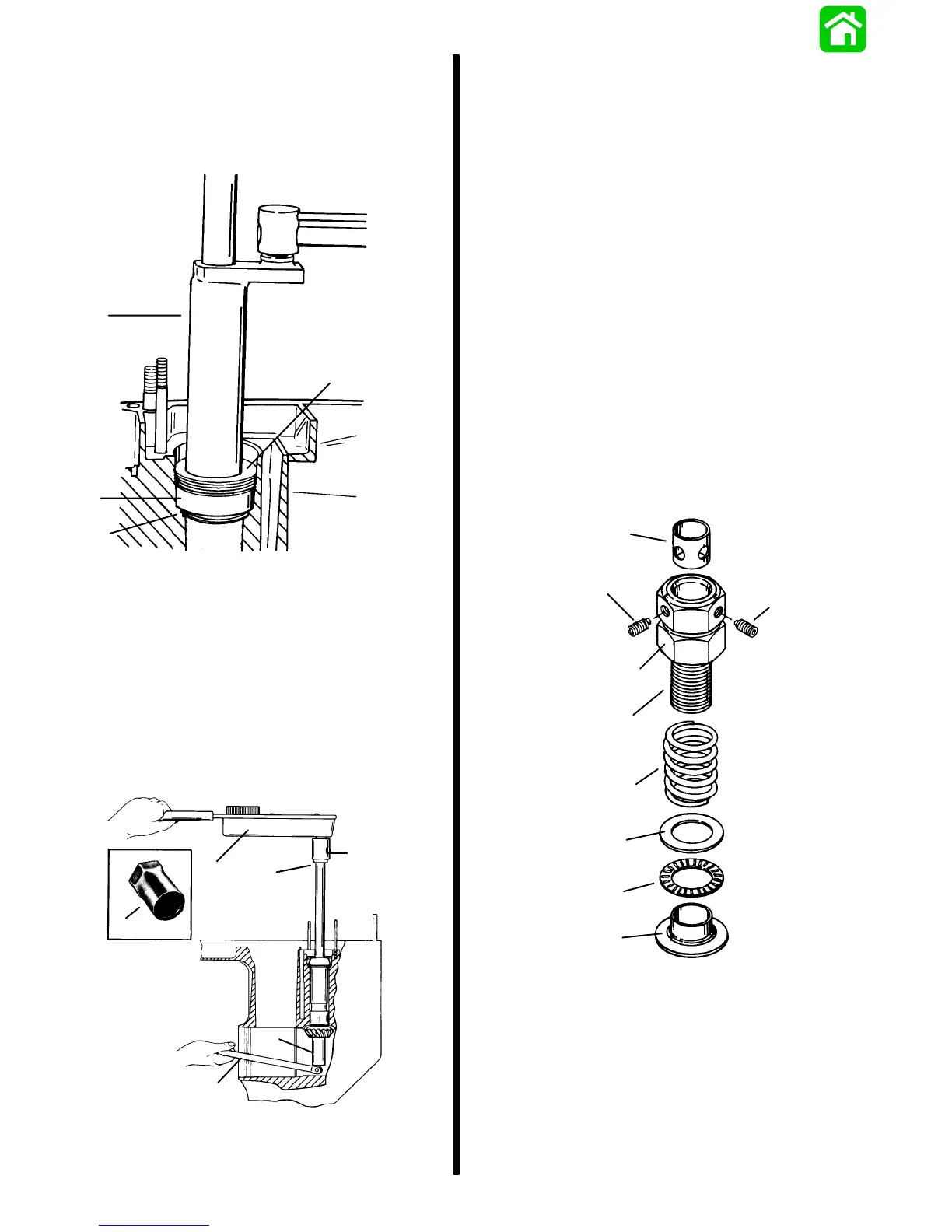

10. Use a socket and flex handle to hold pinion nut

(pad area where flex handle will contact gear

housing while torquing nut).

11. Place Driveshaft Holding Tool (91-34377A1) over

crankshaft end of driveshaft. Torque pinion nut to

75 lb. ft. (101.5 N·m).

a

ba

c

c

d

a - Driveshaft Holding Tool (91-34377A1)

b - Torque Wrench; Torque Nut to 75 lb. ft. (101.5 N·m)

c - Socket

d - Breaker Bar

IMPORTANT: Wipe any excess Loctite from

pinion nut and pinion gear.

Pinion Gear Depth/Forward Gear

Backlash/Reverse Gear Backlash

DETERMINING PINION GEAR DEPTH

NOTE: Read entire procedure before attempting any

change in shim thickness.

IMPORTANT: Forward gear assembly must be

installed in gear housing when checking pinion

gear depth or an inaccurate measurement will be

obtained.

1. Clean the gear housing bearing carrier shoulder.

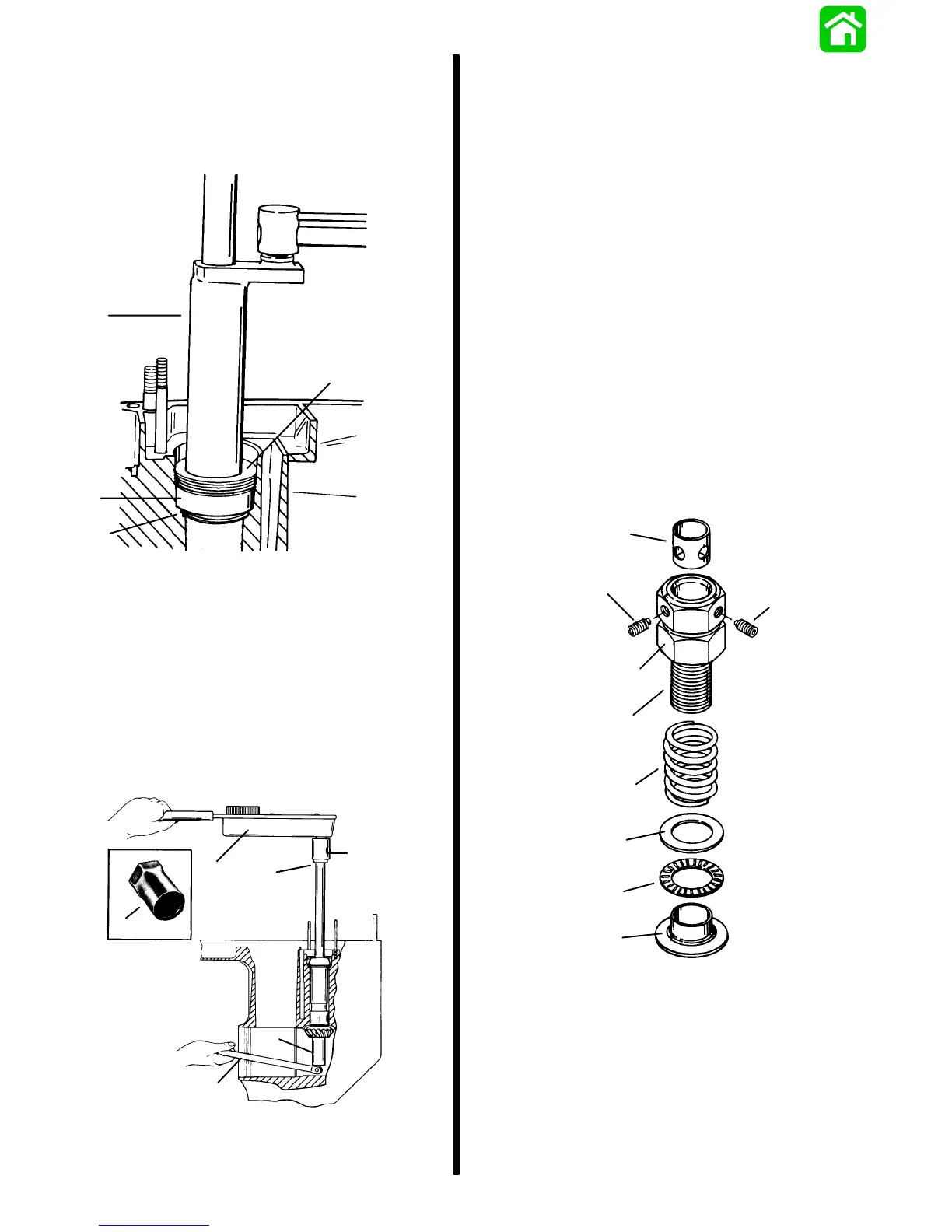

2. Install Bearing Preload Tool (91-14311A1) over

driveshaft in sequence shown.

NOTE: Bearing Preload Tool (91-44307A1) may also

be used. Follow instructions provided with tool for

proper installation.

h

g

g

e

f

d

c

b

a

a - Adaptor

b - Bearing

c - Washer

d - Spring

e - Nut; Thread Nut ALL-the-Way Onto Bolt

f - Bolt

g - Set Screw

h - Sleeve; Holes in Sleeve Must Align with Set Screw

3. Align adaptor on driveshaft bearing pocket ledge.

Loading...

Loading...