90-824052R3 JUNE 2002 ATTACHMENTS/CONTROL LINKAGE - 7-7

STEERING LINK ROD INSTALLATION

IMPORTANT: The steering link rod that connects

the steering cable to the engine must be fastened

using special washer head bolt (“a” - Part Num-

ber 10-14000) and self locking nuts (“b” & “c” -

Part Number 11-34863). These locknuts must

never be replaced with common nuts (non lock-

ing) as they will work loose and vibrate off freeing

the link rod to disengage.

WARNING

Disengagement of a steering link rod can result

in the boat taking a full, sudden, sharp turn. This

potentially violent action can cause occupants to

be thrown overboard exposing them to serious

injury or death.

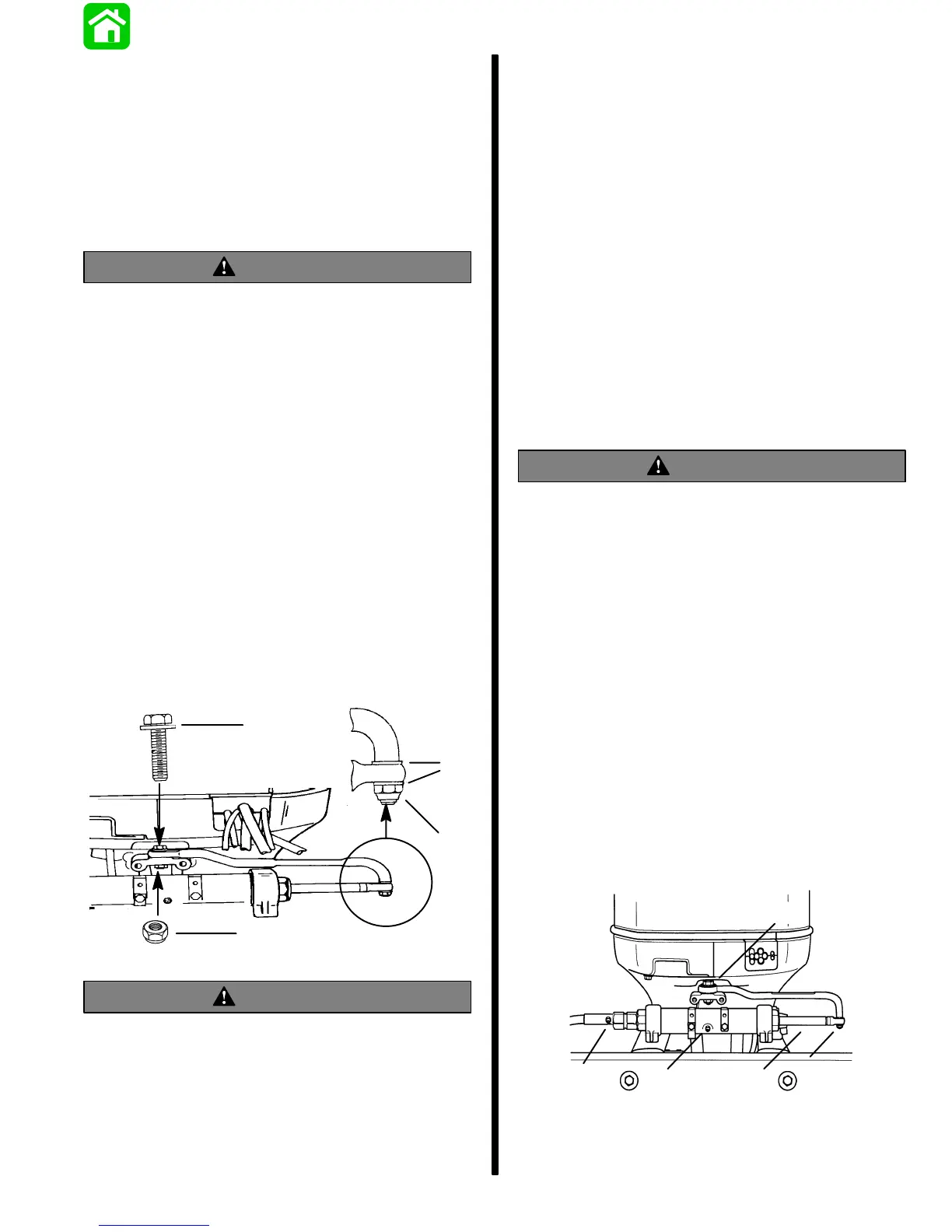

1. Assemble steering link rod to steering cable with

two flat washers (d) and nylon insert locknut (“b”

- Part Number 11-34863). Tighten locknut (b)

until it seats, then back nut off 1/4 turn.

2. Production Outboards - Assemble steering link

rod to engine with special washer head bolt (“a”

- Part Number 10-14000) and nylon insert locknut

(“c” - Part Number 11-34863). First torque bolt (a)

to 20 lb. ft. (27.0 N·m), then torque locknut (c) to

20 lb. ft. (27.0 N·m).

High Performance Outboards - An access hole

is provided through the bottom cowl to ease

installation of the link rod connecting bolt.

Remove the BACK plug for installation and

reinstall after installation.

a

d

c

b

WARNING

After installation is complete (and before

operating outboard), check that boat will turn

right when steering wheel is turned right and that

boat will turn left when steering wheel is turned

left. Check steering thru full range (left and right)

and at all tilt angles to assure interference-free

movement.

Maintenance Instructions

Maintenance inspection is owner’s responsibility and

must be performed at intervals specified, following:

Normal Service - Every 50 hrs. of operation or 60

days (whichever comes first)

*Severe Service - Every 25 hrs. of operation or 30

days (whichever comes first)

*Operation in a salt water area is considered

“Severe Service.”

1. Carefully check steering system components for

wear. Replace worn parts.

2. Check steering system fasteners to be sure that

they are torqued to correct specifications.

NOTE: RideGuide Steering Cables are lubricated at

the factory and require no additional lubrication at

initial installation.

WARNING

Core of each steering cable (transom end) must

be fully retracted into cable housing before lubri-

cating cable. If cable is lubricated while ex-

tended, hydraulic lock of cable could occur.

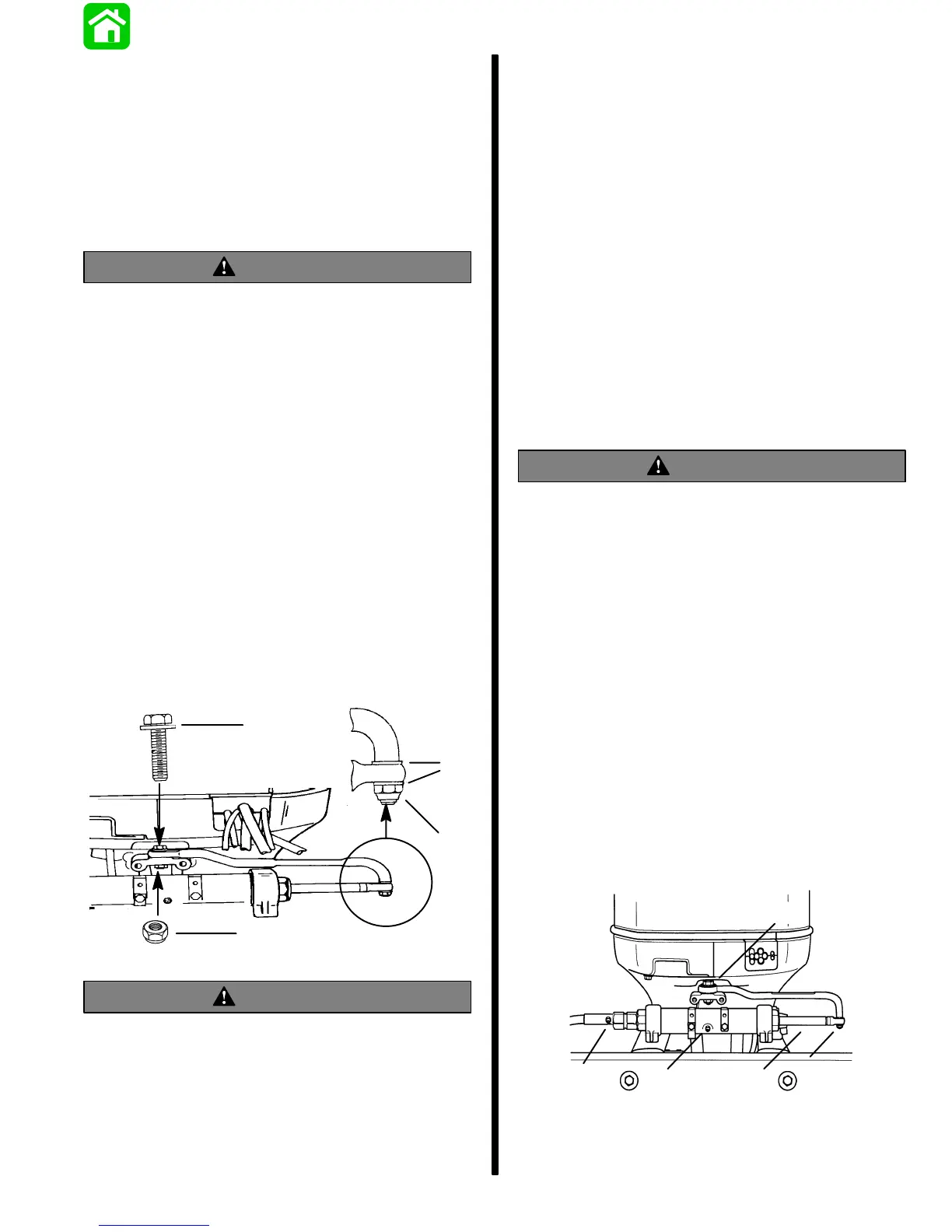

3. With core of RideGuide Steering Cable (transom

end) fully retracted, lubricate transom end of

steering cables thru grease fittings (a) with 2-4-C

w/Teflon (92-825407A12). Lubricate exposed

portion of cable end (b) with 2-4-C w/Teflon.

4. Lubricate pivot point (c) of steering link rod and

ball joint (d) of link rod with SAE 30 Weight Oil.

5. Inspection and lubrication of steering head

assembly (rotary or straight rack) should be

performed once each year (by your Authorized

Dealer) or whenever steering mount and/or

steering head are disassembled, or if steering

effort has increased. Lubricate with 2-4-C

w/Teflon.

28169

a

a

b

c

d

Loading...

Loading...